Method and device for exhaust gas management

a technology of exhaust gas management and exhaust inserts, applied in the direction of engines, mechanical equipment, machines/engines, etc., can solve the problems of poor engine performance, exhaust inserts that would produce detrimental effects on stock exhaust systems, etc., and achieve the effect of increasing horsepower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

)

[0031]The inventive concept will now be described more fully hereinafter with reference to the accompanying drawings, through which some, but not all possible embodiments of the invention are shown. Indeed, the inventive concept may be embodied in various forms and should not be construed as limited to the particular embodiments set forth herein.

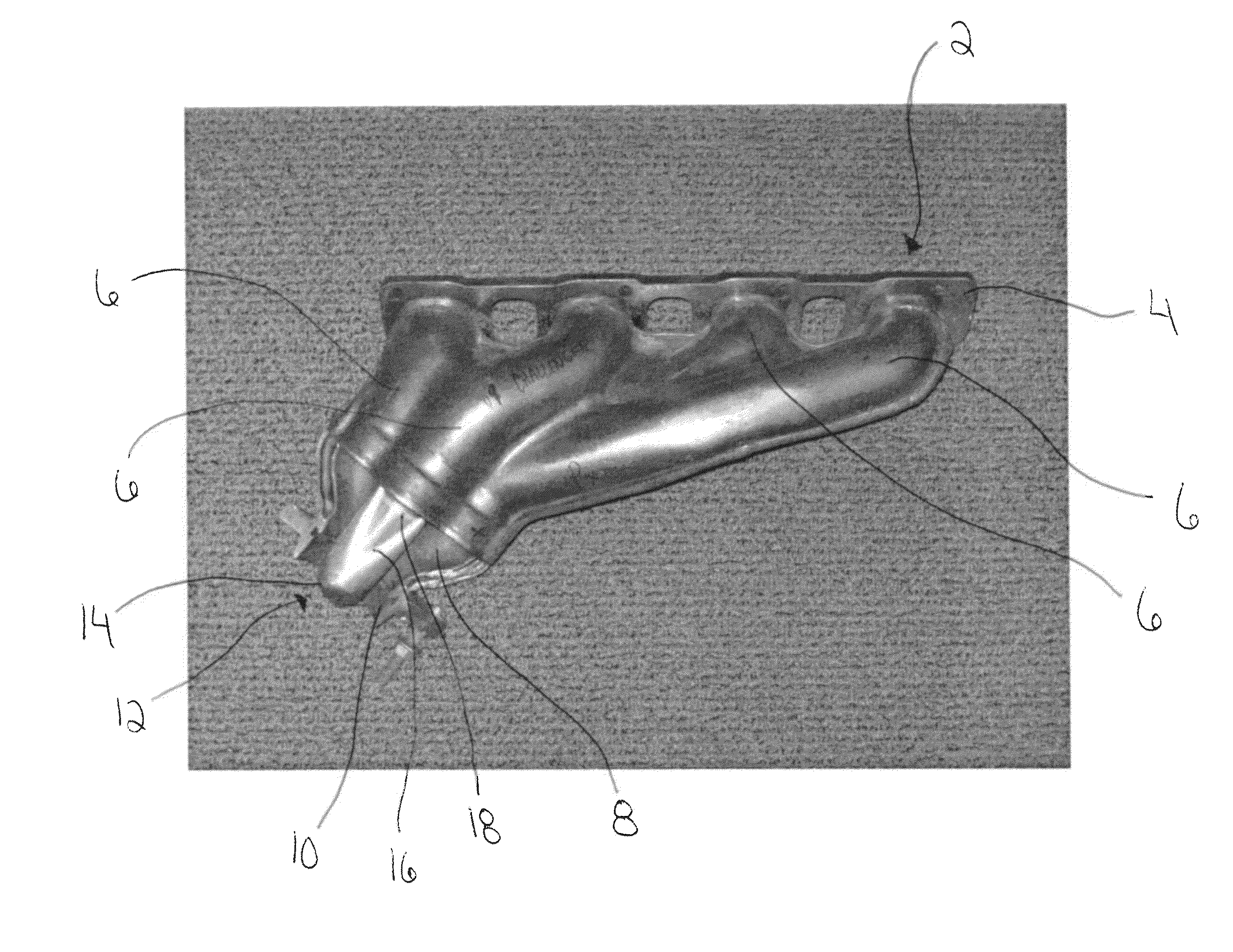

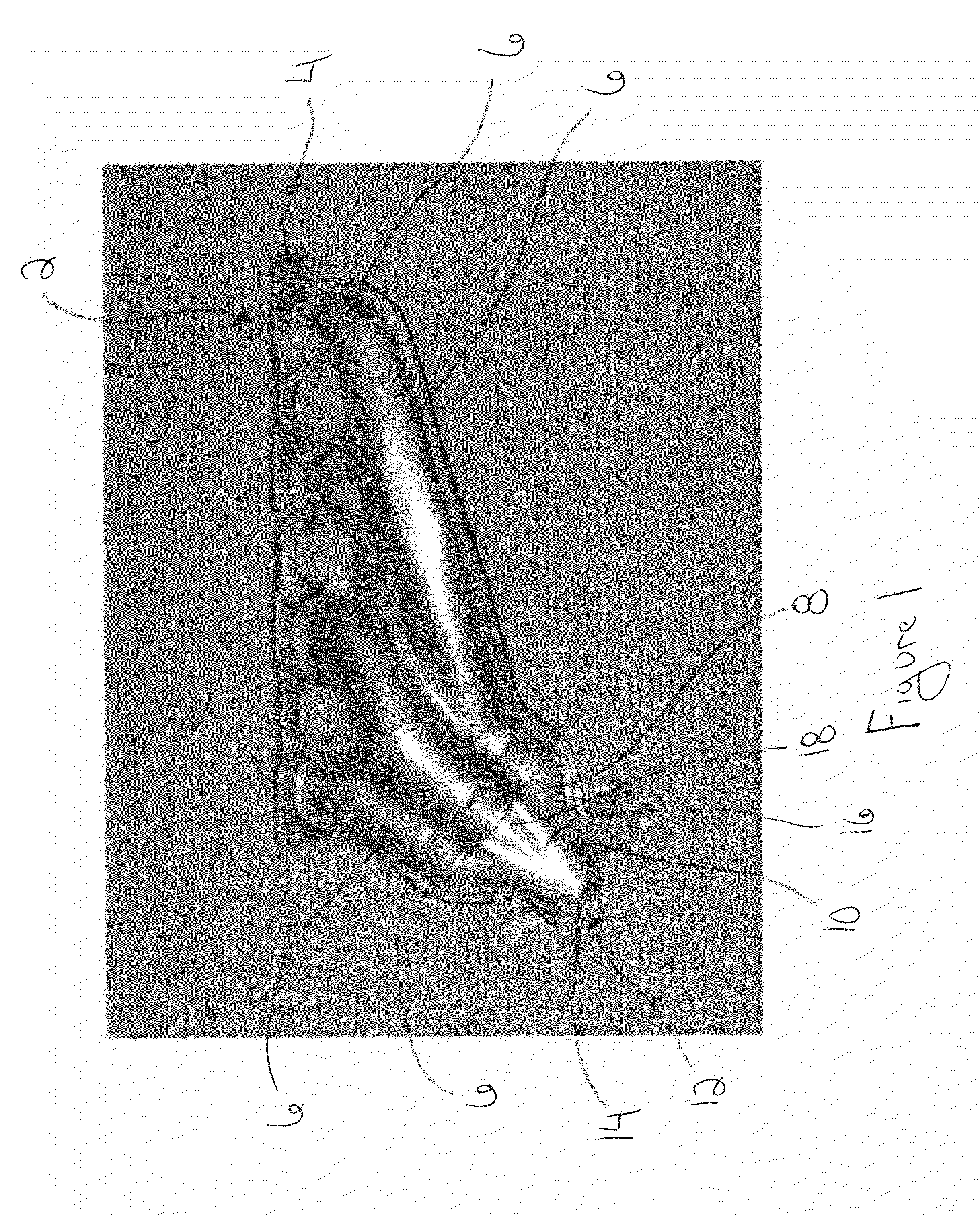

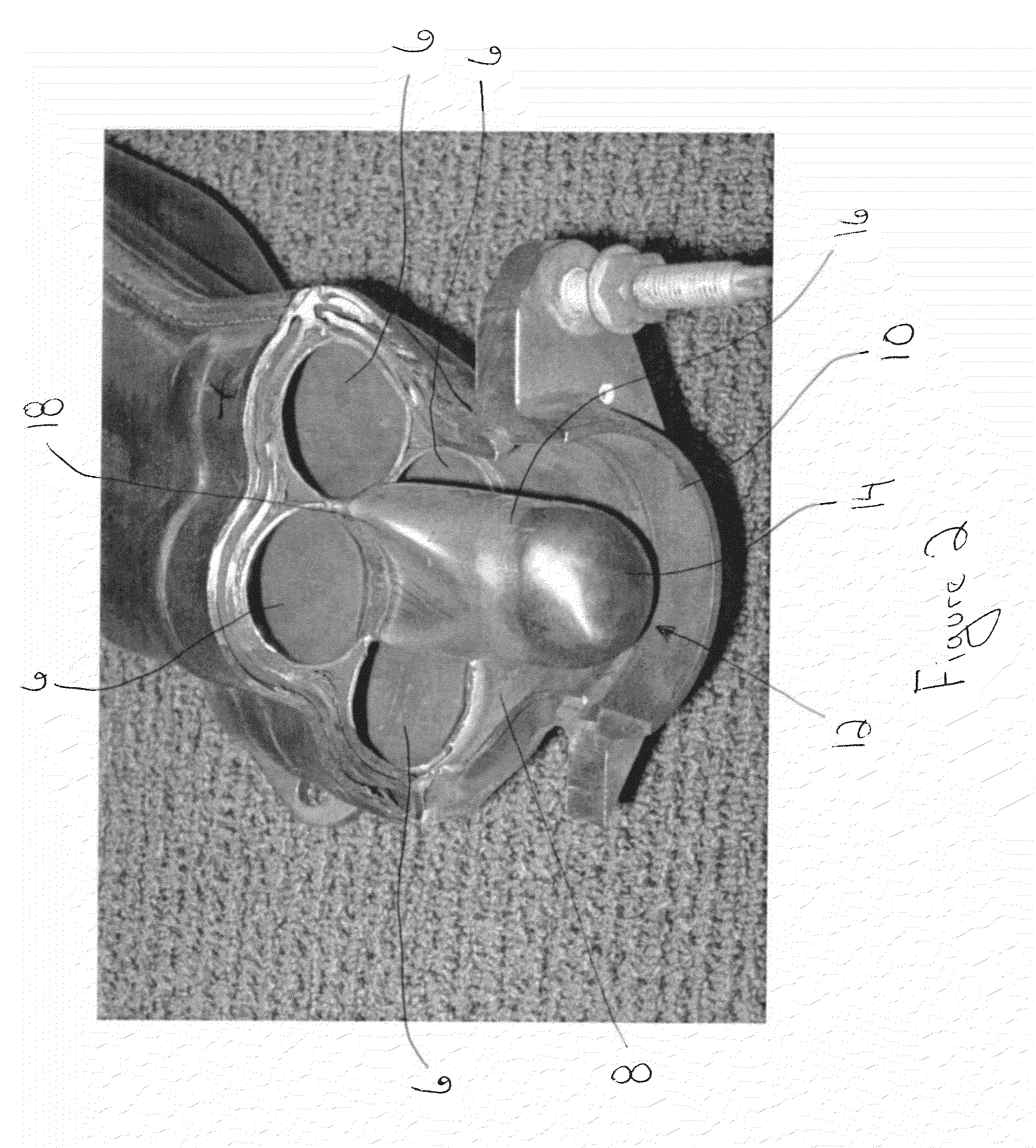

[0032]FIG. 1 is a perspective view of an original manufacturer exhaust system 2. As shown in FIG. 1, the exhaust system 2 includes a flange 4, conduits 6 and a collector 8. The flange 4 is formed to the dimensions and shape of the engine (not shown in the Figures) to which it is to be attached. As shown in FIG. 1, the flange 4 may be coupled to the engine with mechanical fasteners, such as bolts. The conduits 6 extend from the flange 4 to the collector 8. The conduits 6 may be of varying length depending on the space available in the engine compartment. The flange 4 has openings therein to allow exhaust gas from an engine's cylinders to pas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com