Air compressor unit

a compressor and air technology, applied in the direction of pumps, mechanical equipment, liquid fuel engines, etc., can solve the problems of high construction complexity of compressors of this type, high precision machining and assembly of components, and cumbersomeness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

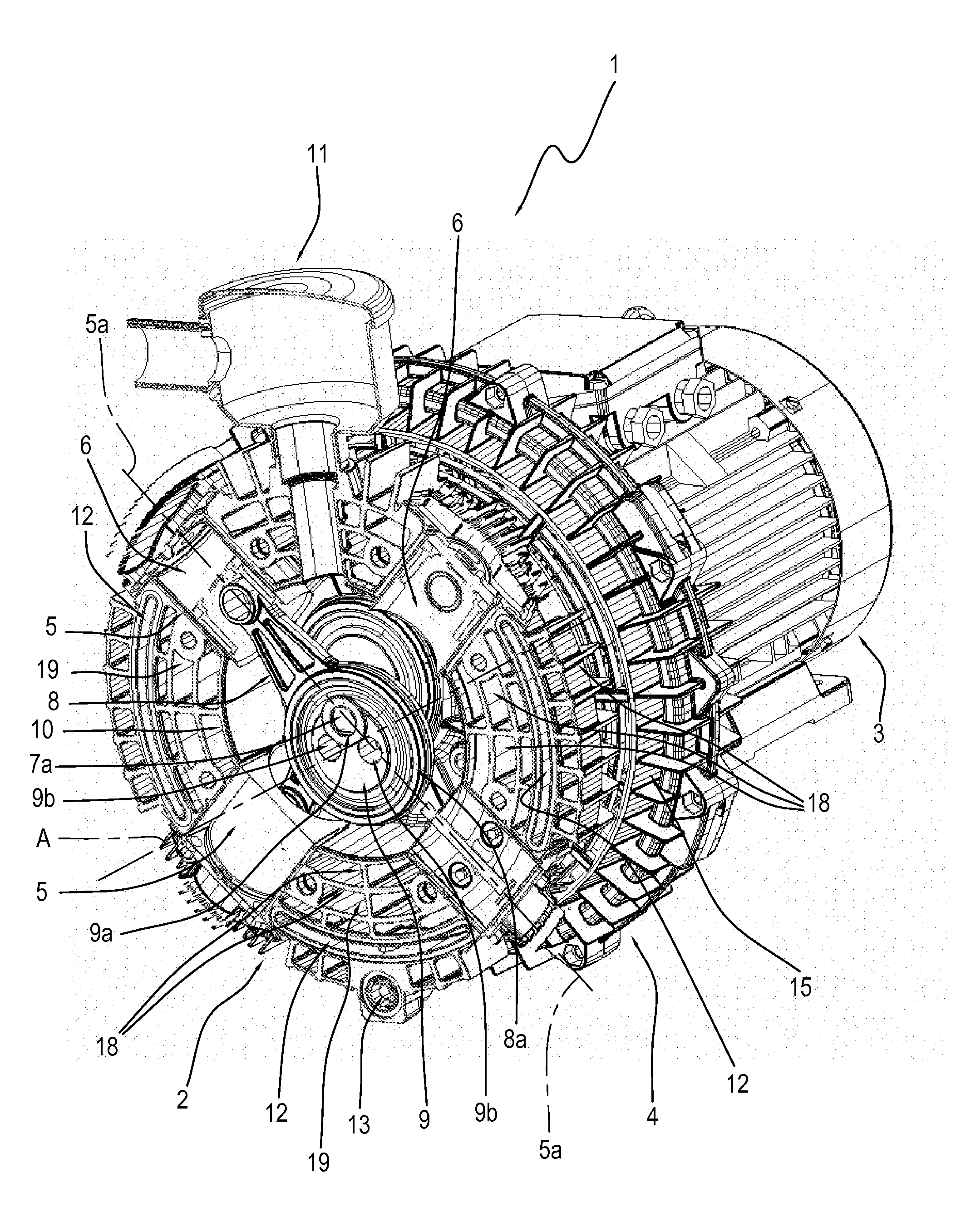

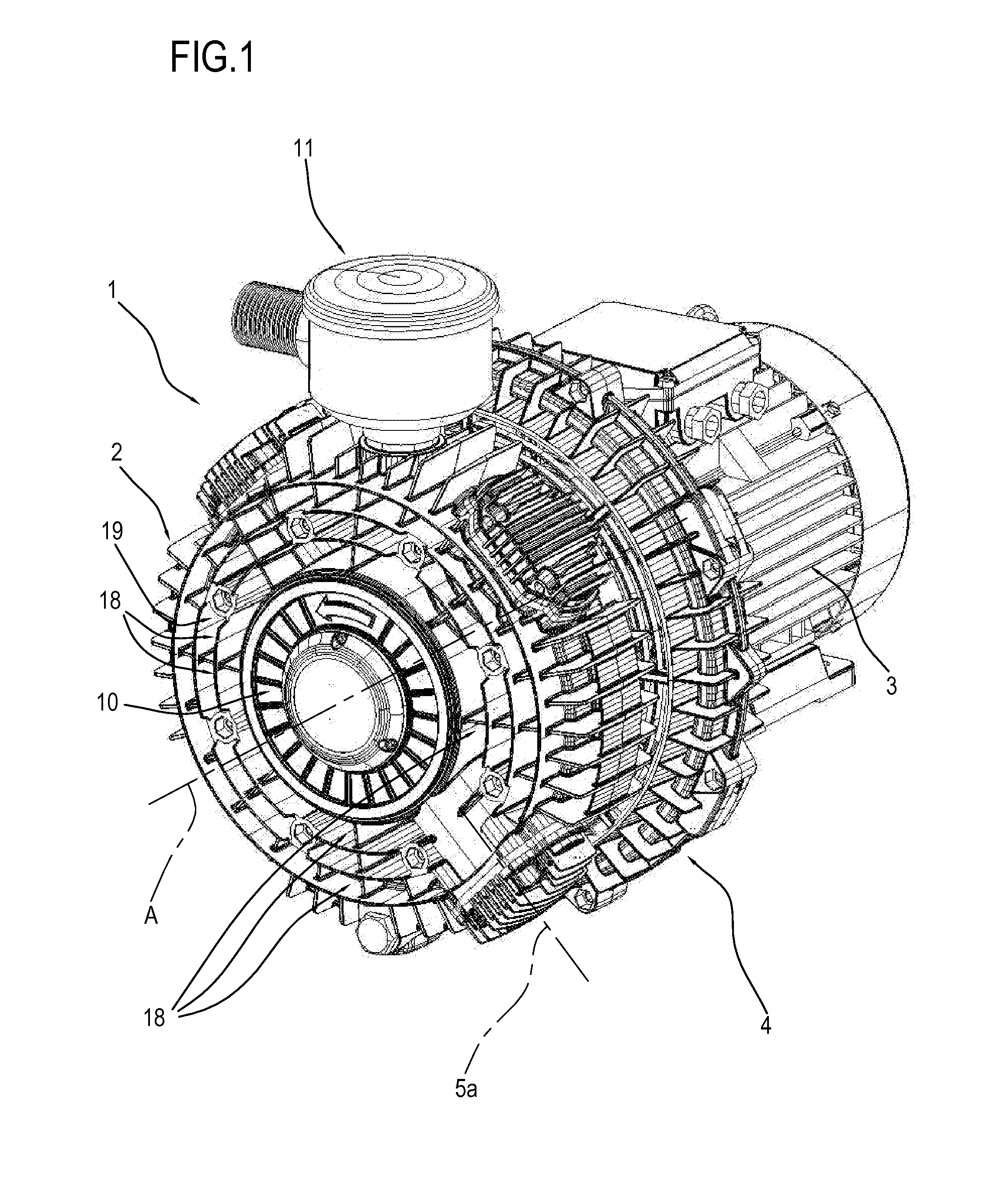

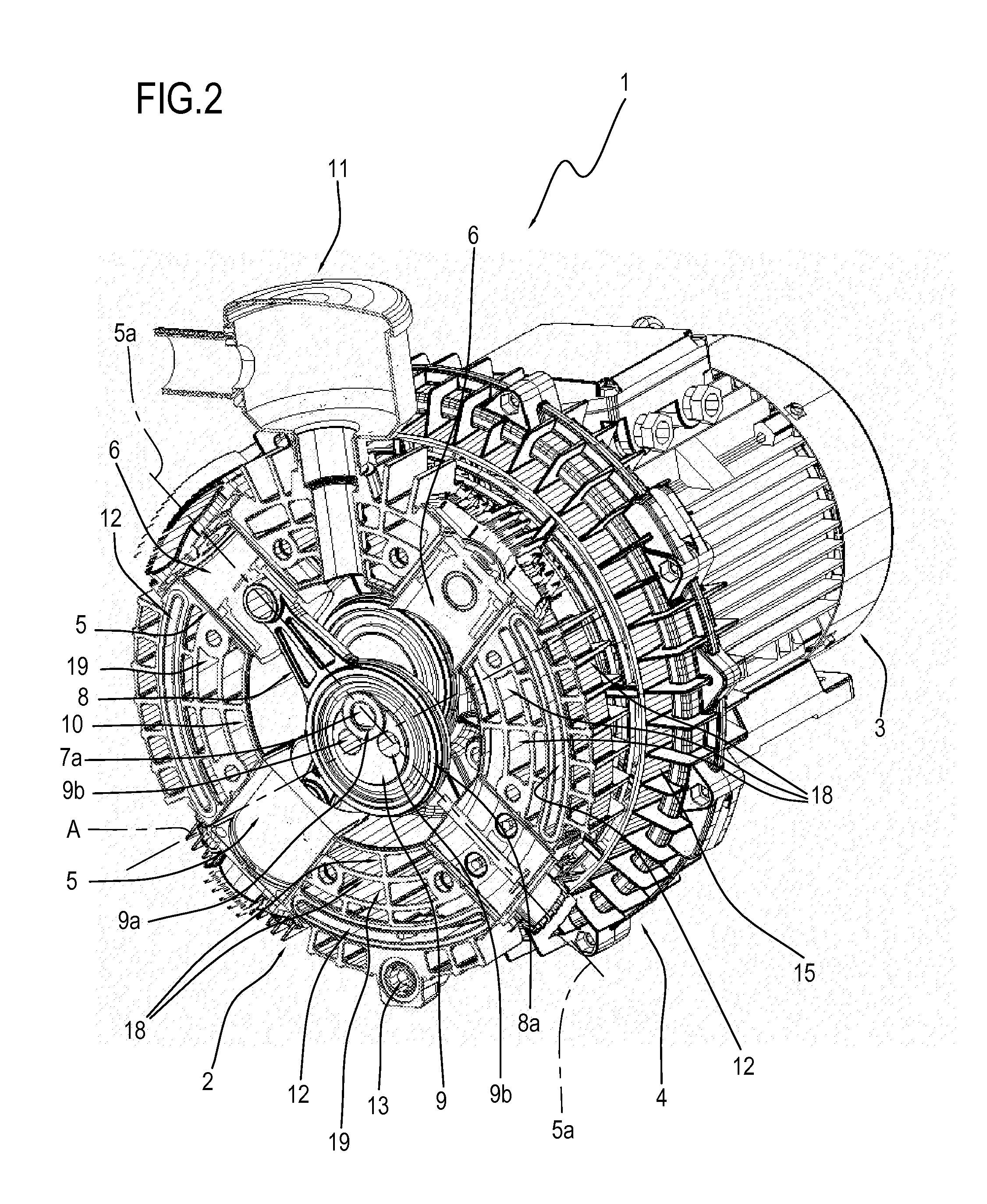

[0023]In the accompanying drawings, the reference numeral 1 denotes a volumetric reciprocating compressor for compressing air for use preferably by pneumatic tools.

[0024]As clearly illustrated in FIGS. 1 and 2, the compressor 1 comprises an air compressing unit 2, a motor 3 for driving the compressing unit 2 and a cooling unit 4 by which the compressed air from the unit 2 is cooled.

[0025]As illustrated in FIGS. 2 and 3, the air compressing unit 2 comprises a plurality of cylinders 5 (four in the embodiment illustrated), within which respective reciprocating pistons 6 are received.

[0026]The motor 3, which is advantageously an electric motor, has a shaft 7 which rotates about a respective axis of rotation A.

[0027]As described in detail below, the rotating shaft 7 protruding from the motor 3 drives both the cooling unit 4 and the compressing unit 2.

[0028]Each piston 6 is kinematically connected to the shaft 7 by a respective con rod 8 and a crank lever member 9.

[0029]The crank lever me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com