Passage channel for a turbomachine and turbomachine

a technology of passage channel and turbomachine, which is applied in the direction of motors, air transportation, climate sustainability, etc., can solve the problems of high noise development, heavy secondary flows, energy transmission losses, etc., and achieve the effects of minimizing energy transmission losses, improving inflow, and high degree of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

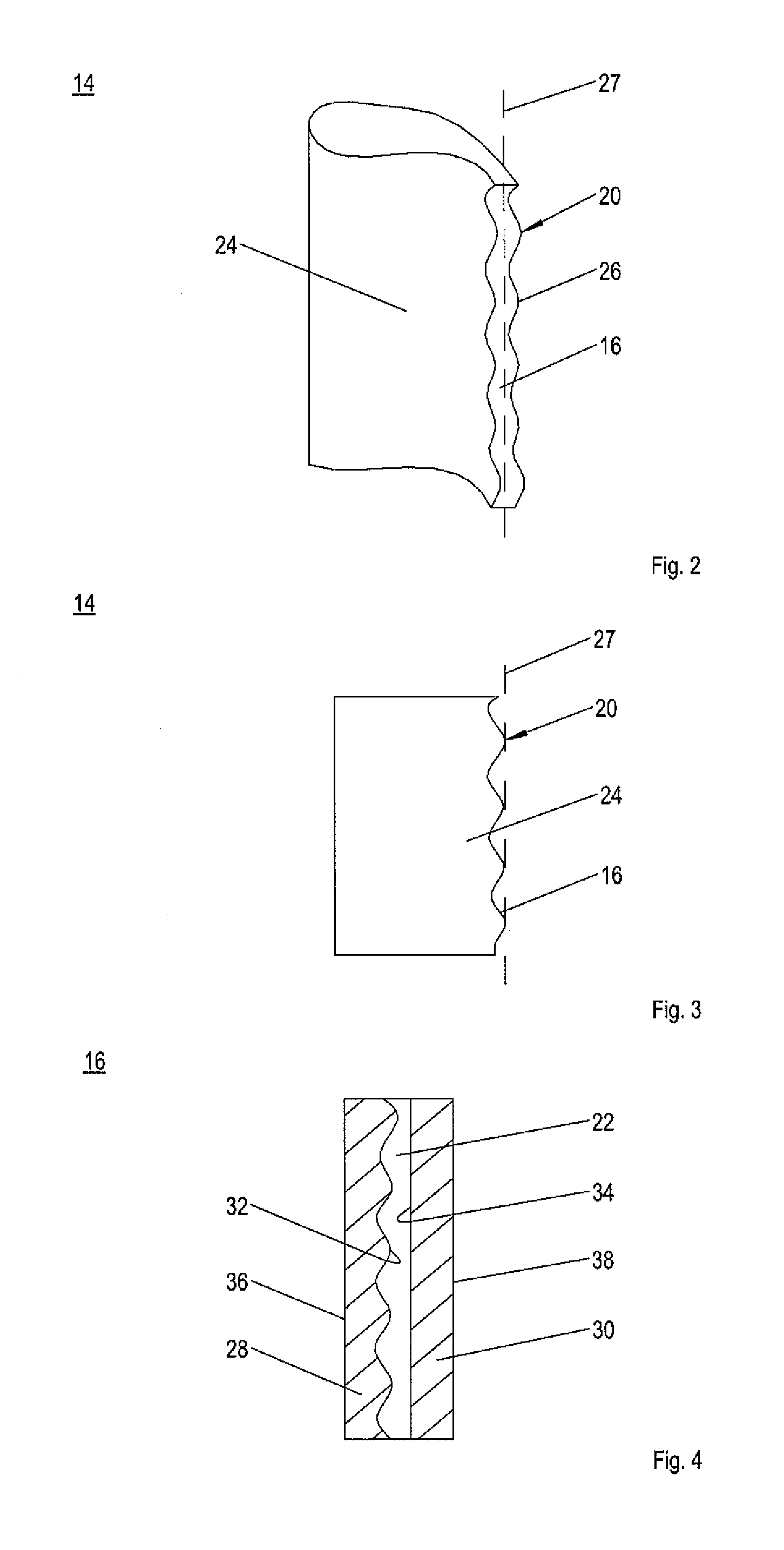

[0033]In the figures, identical structural elements are denoted with the same reference numeral, for the sake of clarity only one element being or may be provided with a reference numeral in the case of multiple identical elements in one figure.

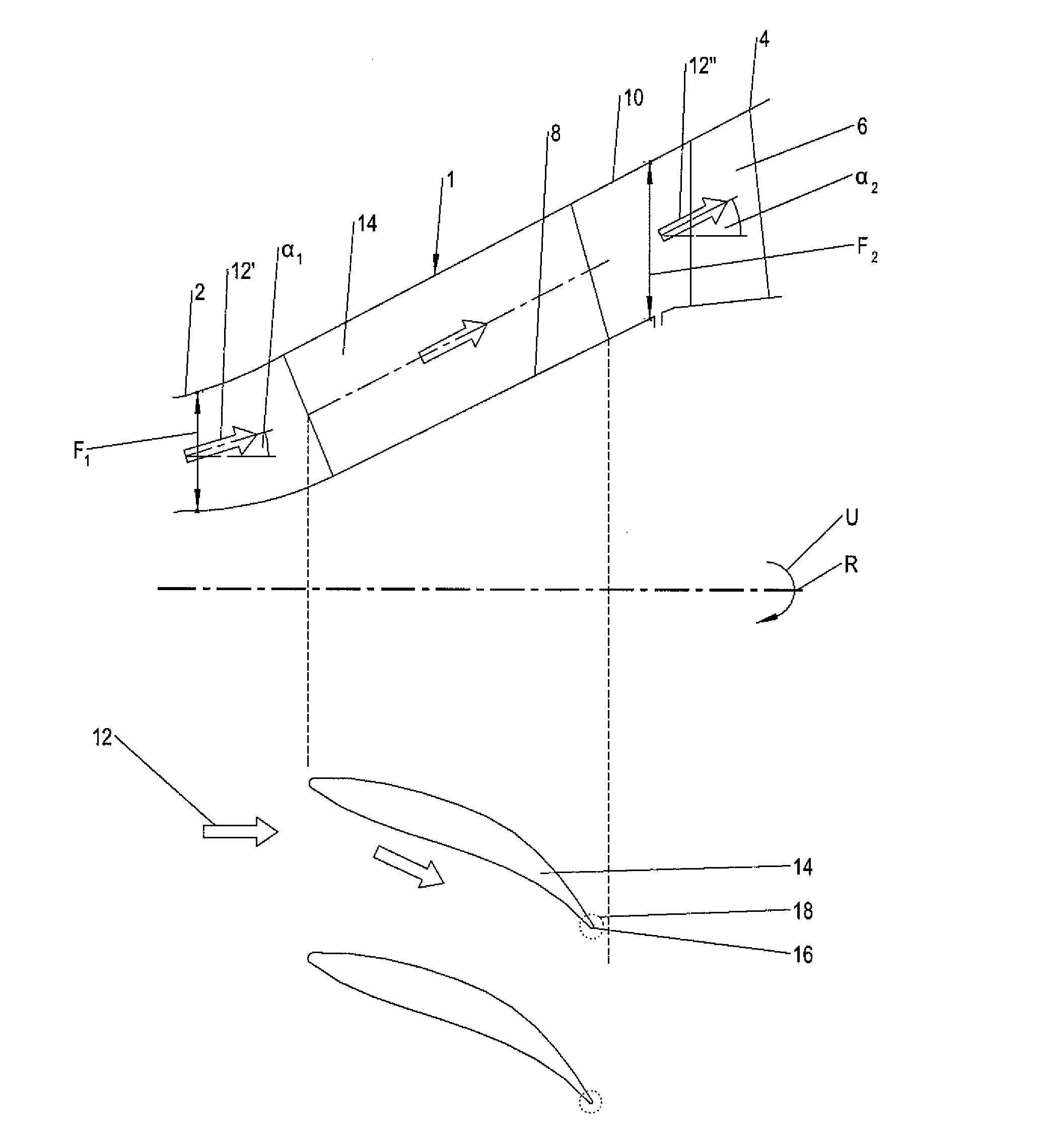

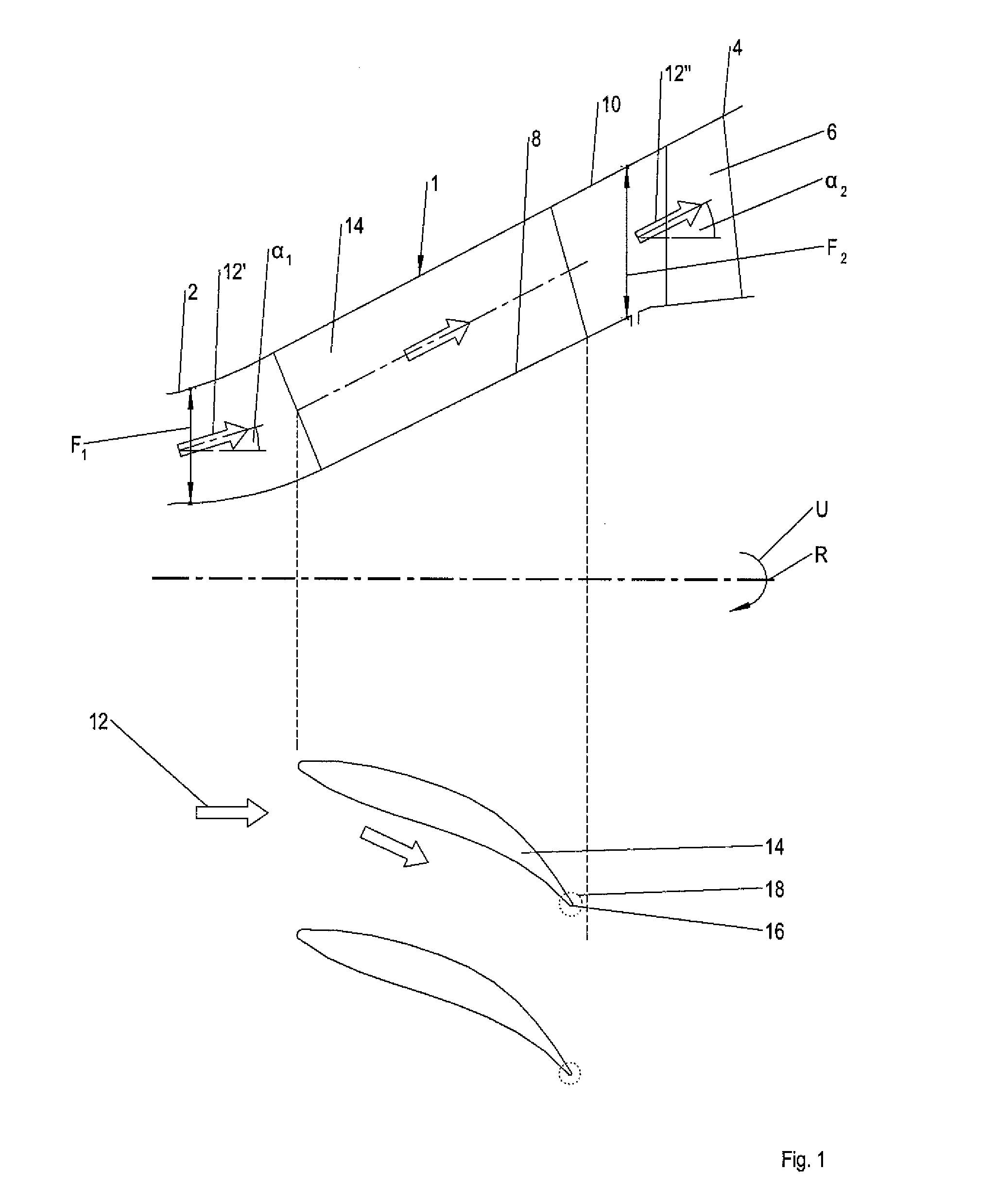

[0034]FIG. 1 shows an example of a transition duct 1 between a high pressure turbine 2 and a low-pressure turbine 4 of an axial turbomachine, such as an aircraft engine, in an axial half section or meridian section (upper part of the figure) as well as in a planar developed view or in a profile section (lower part of the figure).

[0035]Transition duct 1 is mounted in a stationary manner in a turbine housing, while high pressure turbine 2 and low pressure turbine 4 each have moving blade rows 6 which rotate around a rotation axis or turbine axis R in rotation direction U. Transition duct 1 encompasses rotation axis R and has an annular flow cross section. It has a radially inner duct wall 8, a radially outer duct wall 10 and a high pressure tur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com