Modular Electric Wall Heater

a heater and module technology, applied in the field of heater technology, can solve the problems of inefficiency of assembly line production, inconvenient maintenance, and inconvenient maintenance, and achieve the effects of reducing maintenance costs, improving production efficiency, and saving space and transportation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

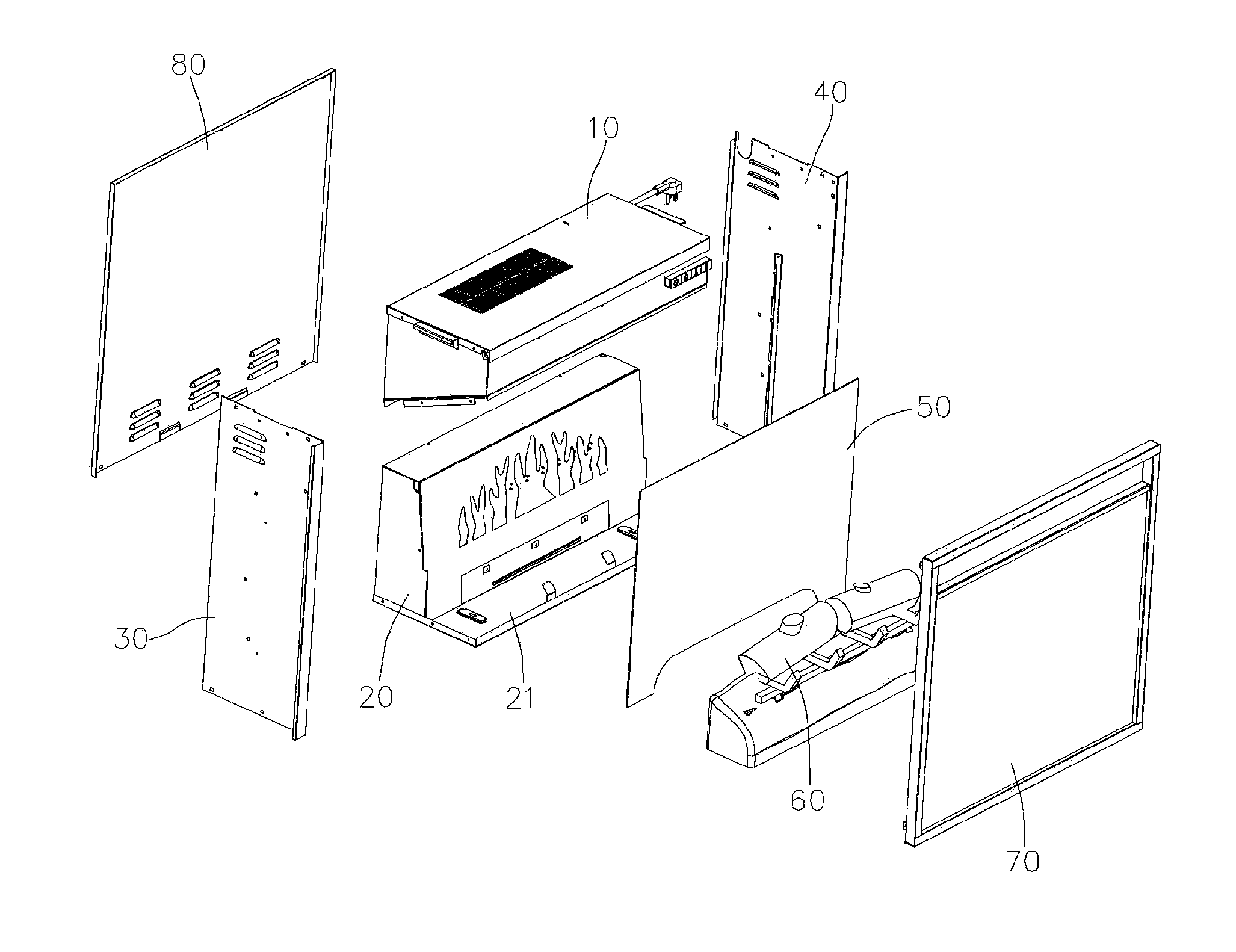

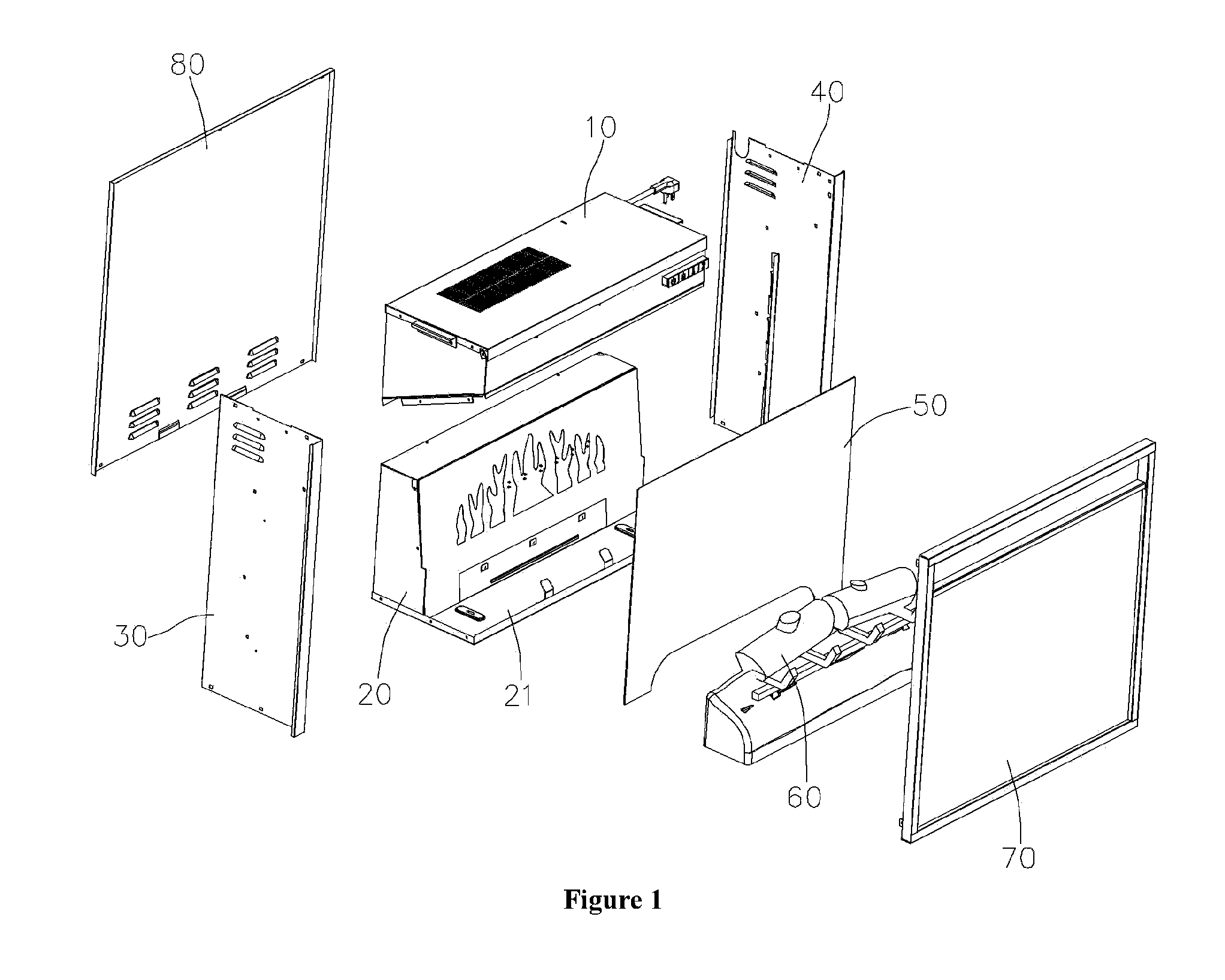

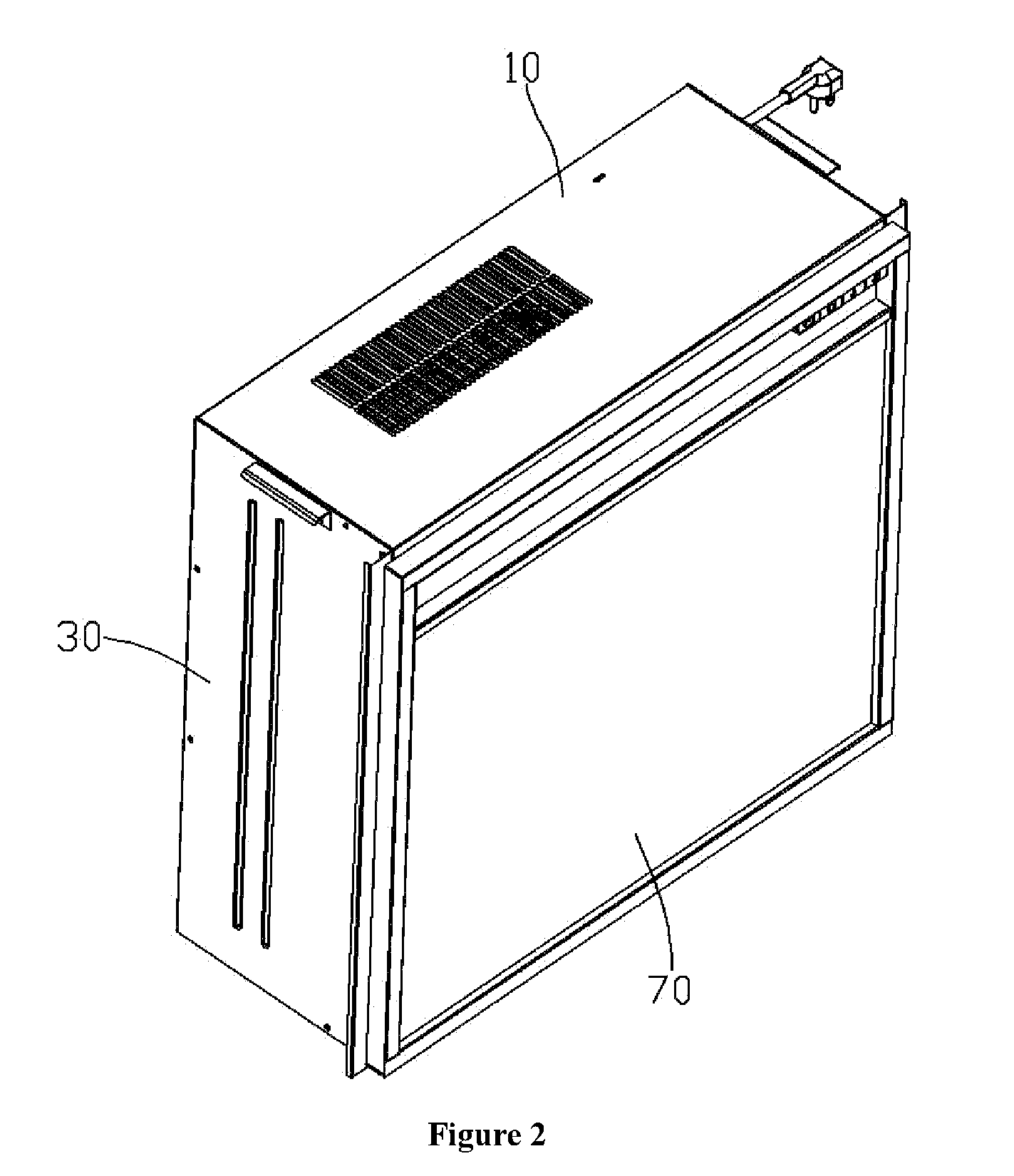

[0018]As shown in FIG. 1 through FIG. 7: the present invention of modular electric wall heater (heater) comprises an upper main box component 10, a lower main box component 20, a left side panel component 30, a right side panel component 40, a flame simulator component 50, a fake ashes component 60, a front panel component 70 and a rear panel component 80, wherein, the upper main box component 10 is a closed structure and enclosing, at least, a heater 11, a fan motor 12, an air outlet channel 13 and enclosing other elements not shown in the drawings: a main control circuit board, a control key board, a receiver, a power cord or power cord slot, a Negative Temperature Coefficient Thermistor (NTC), a shell box, fan motor seat, an air filter or an air outlet. The lower main box component 20 can also be a closed structure, enclosing, at least, a bottom panel 21, a flame PCB light strip 22, a blue light PCB light strip 23, a gray PCB light strip 24, a screen film 25 imprint with flame de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com