Nanofluid for thermodynamic solar system

a solar system and nanofluid technology, applied in the direction of solar heat collectors with working fluids, solar heat collectors for particular environments, solar-ray concentration, etc., can solve the problems of considerable technological character, achieve the effect of improving the thermodynamic performance of the solar system, and improving the control of the thermodynamic solar plan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

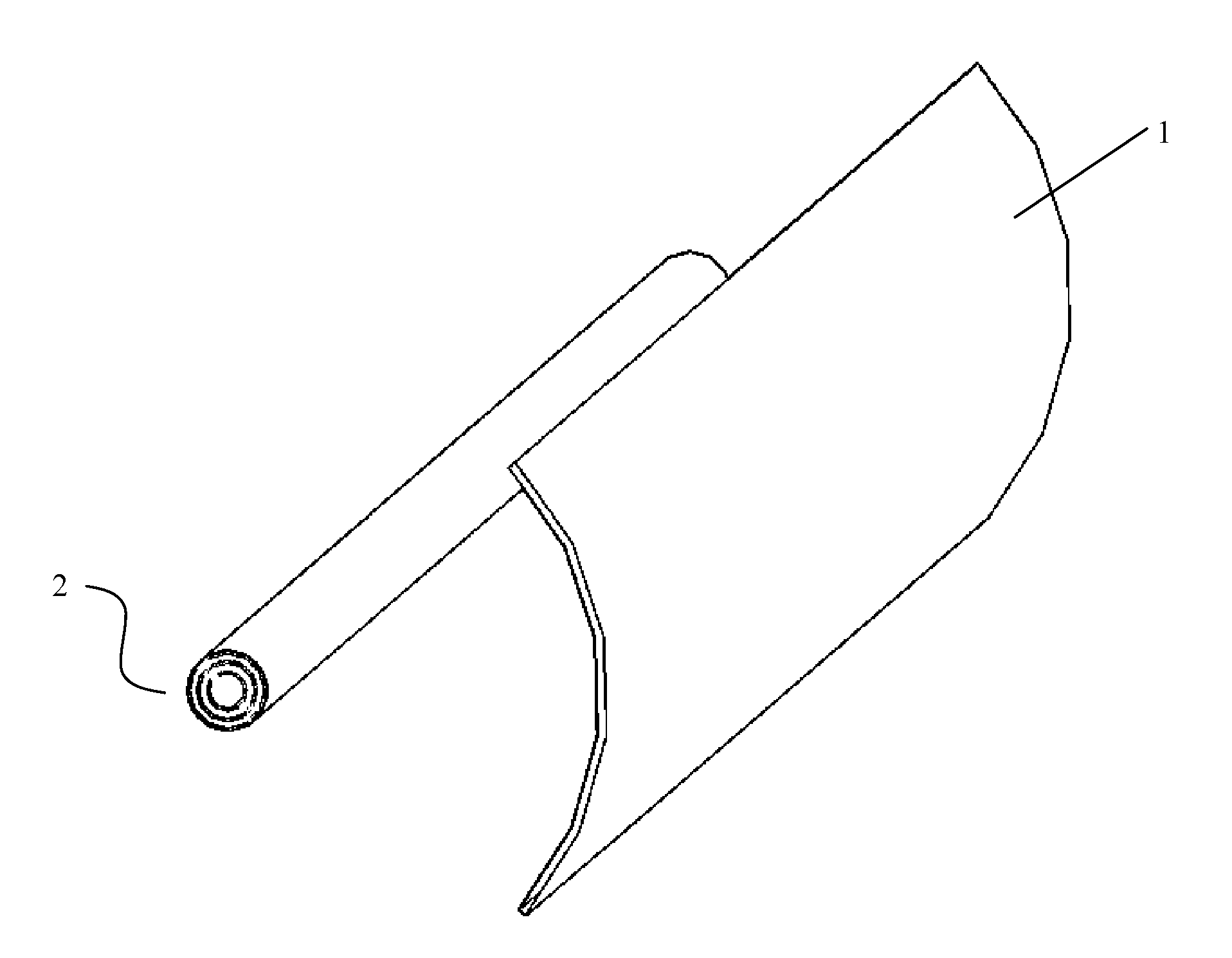

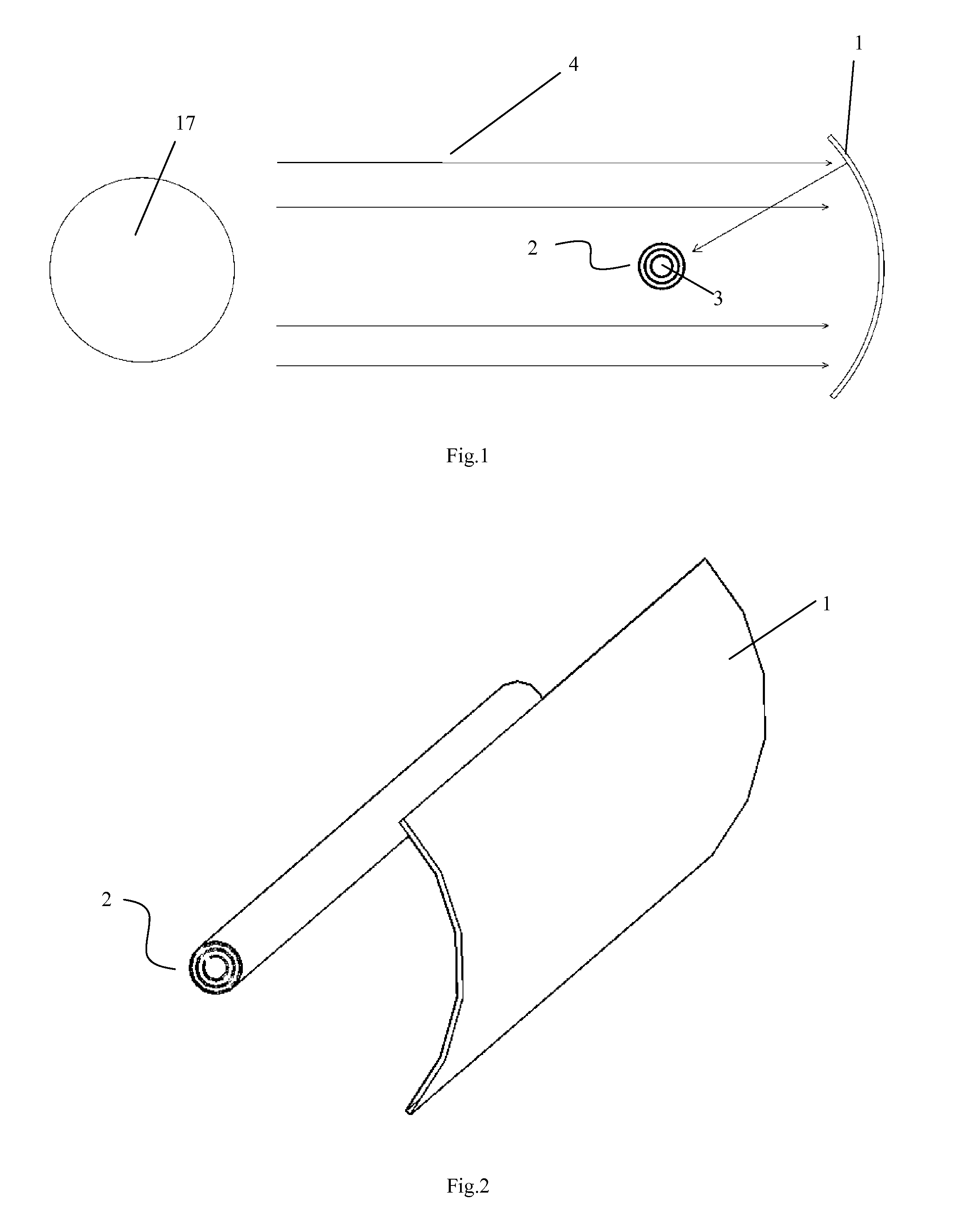

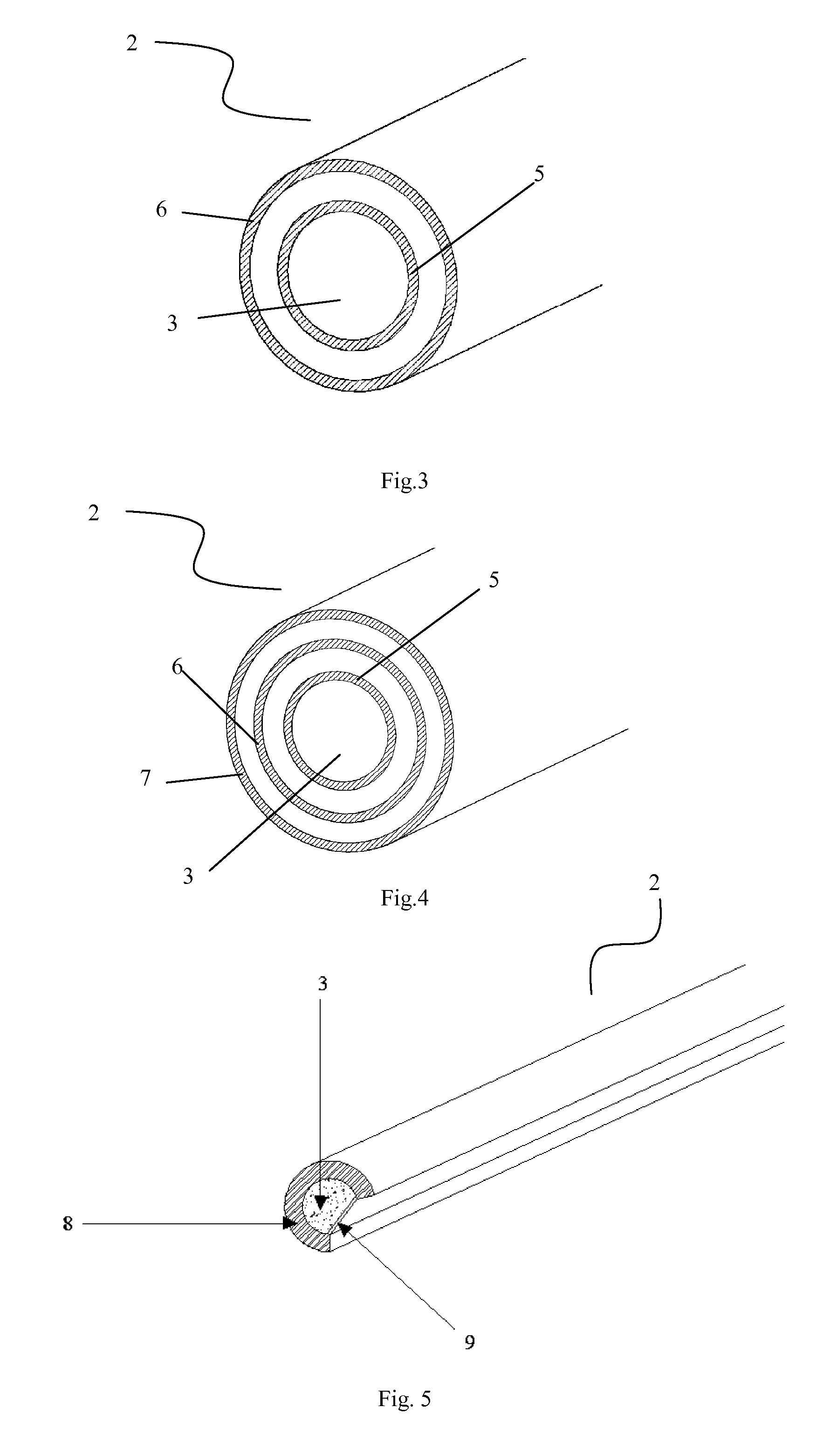

[0019]As it is shown in the appended drawings 1 and 2, the present invention provides to arrange in the focal position of the solar concentrator mirror 1 a newly designed receiver 2, inside which the gas-based nanofluid 3 flows, which warms itself upon direct absorption of the concentrated solar radiation 4 coming from the sun 17. Nanofluid stands for any fluid, inside which nanometric particles are dispersed, which are able to improve the conductive convective, and radiative thermal exchange capacity of the base fluid. In particular, the nanofluids are made up of a base fluid to which nanometric powders of metal oxides are added (CuO, Fe2O3, TiO2, ZnO, MoO3, etc . . . ) or other materials in order to optimize the thermal properties of the heat transfer fluid. As it is stated before, in the proposed invention heat transfer fluid may be a mixture of a gas with absorbing sub-micrometer particles (CuO, Fe2O3, TiO2, ZnO, MoO3 or other materials as for example metals). The gas-based nano...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com