Cooling assembly and dehumidification method

a technology of cooling assembly and dehumidification method, which is applied in the direction of defrosting, heating types, domestic cooling apparatus, etc., can solve the problems of increasing climate problems, and affecting the cooling effect of electronic components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

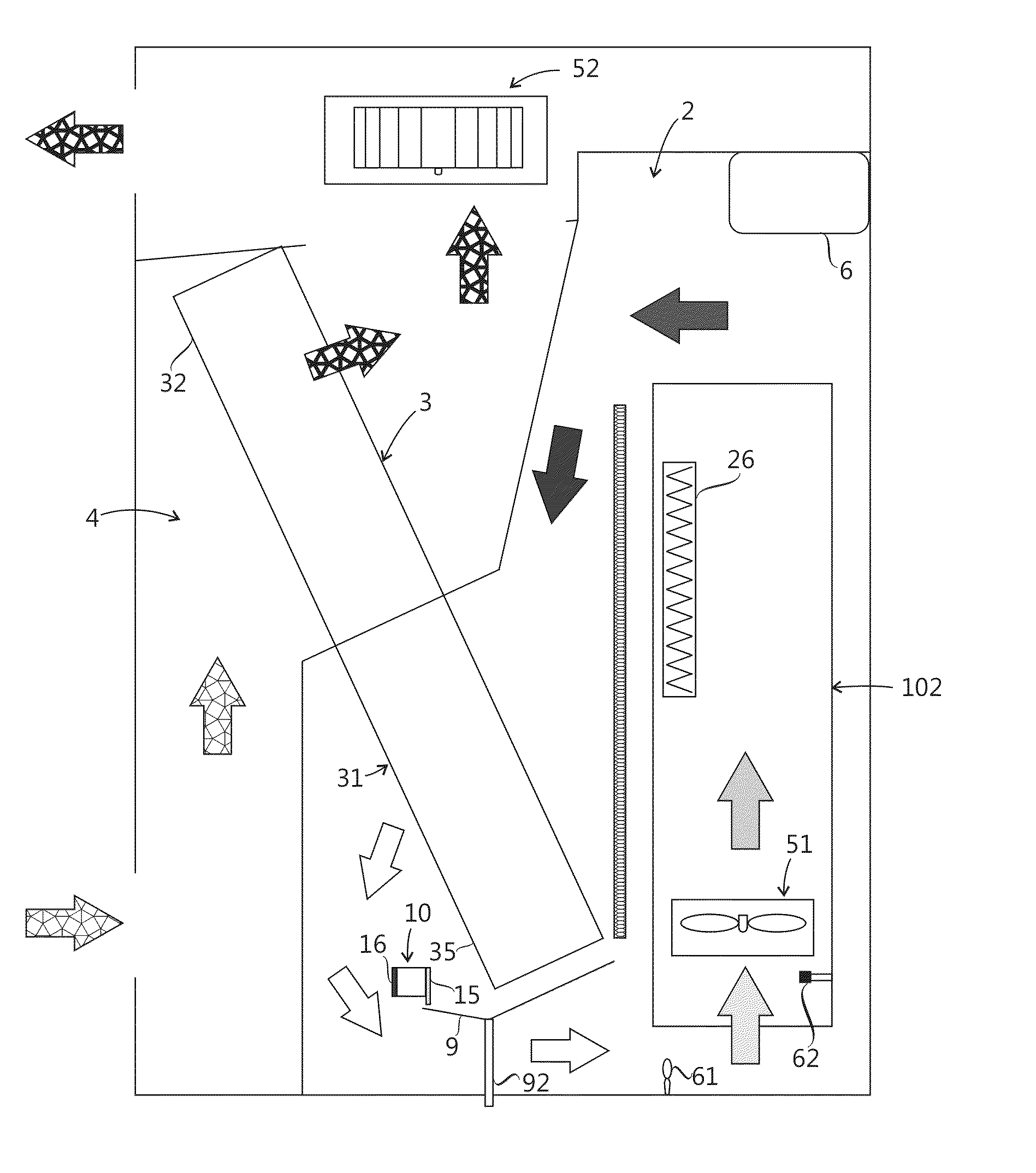

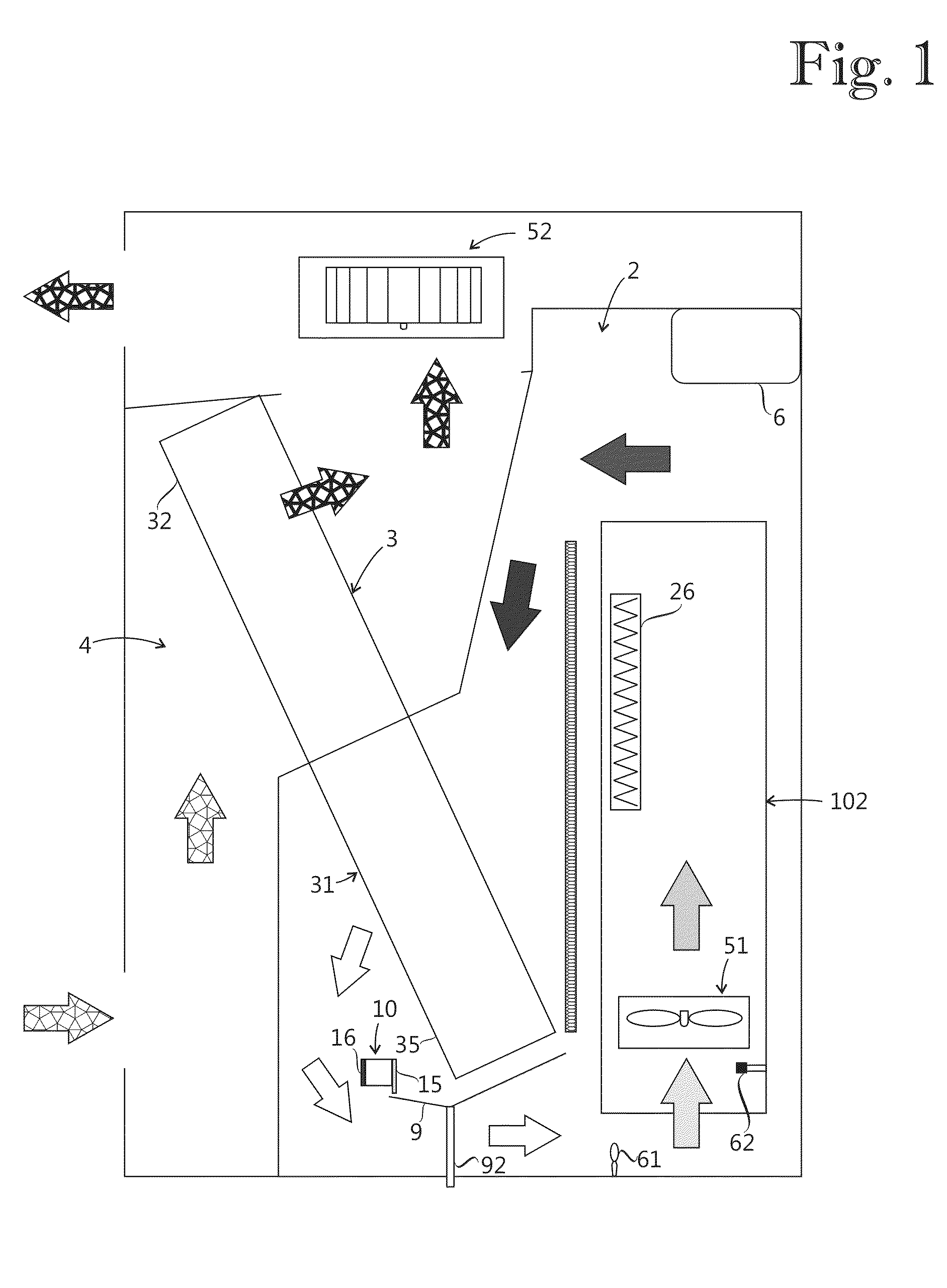

[0010]Exemplary embodiments of the present disclosure provide a method and an apparatus for implementing the method so as to alleviate the above disadvantages. Exemplary embodiments of the present disclosure provide a dehumidification method and a cooling assembly as described herein.

[0011]Exemplary embodiments of the present disclosure are based on the idea of condensing water from a device chamber cooling medium by cooling thereof at a safe place at a distance from electronic components that could be damaged by humidity. The condensed water may be discharged from a device chamber containing the electronic components or stored inside the device chamber in a harmless place where the water does not endanger the electronic components.

[0012]An advantage of the method and assembly of the present disclosure is that the cooling medium in a device chamber can be dried relatively fast without need to discharge heated cooling medium from the device chamber.

[0013]In the following, exemplary e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com