Air-cooling cylinder head of gasoline engine and gasoline engine having the same

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

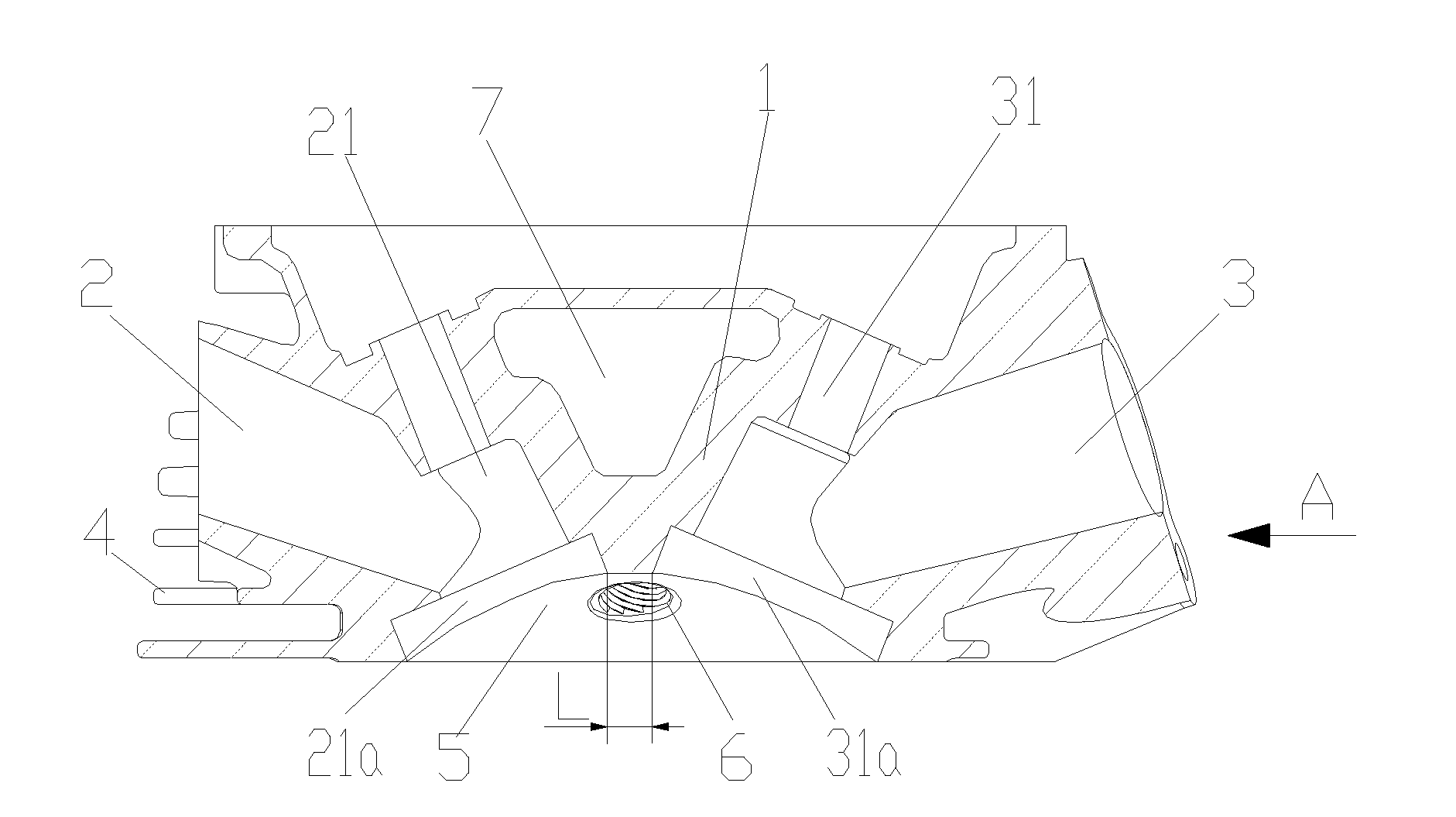

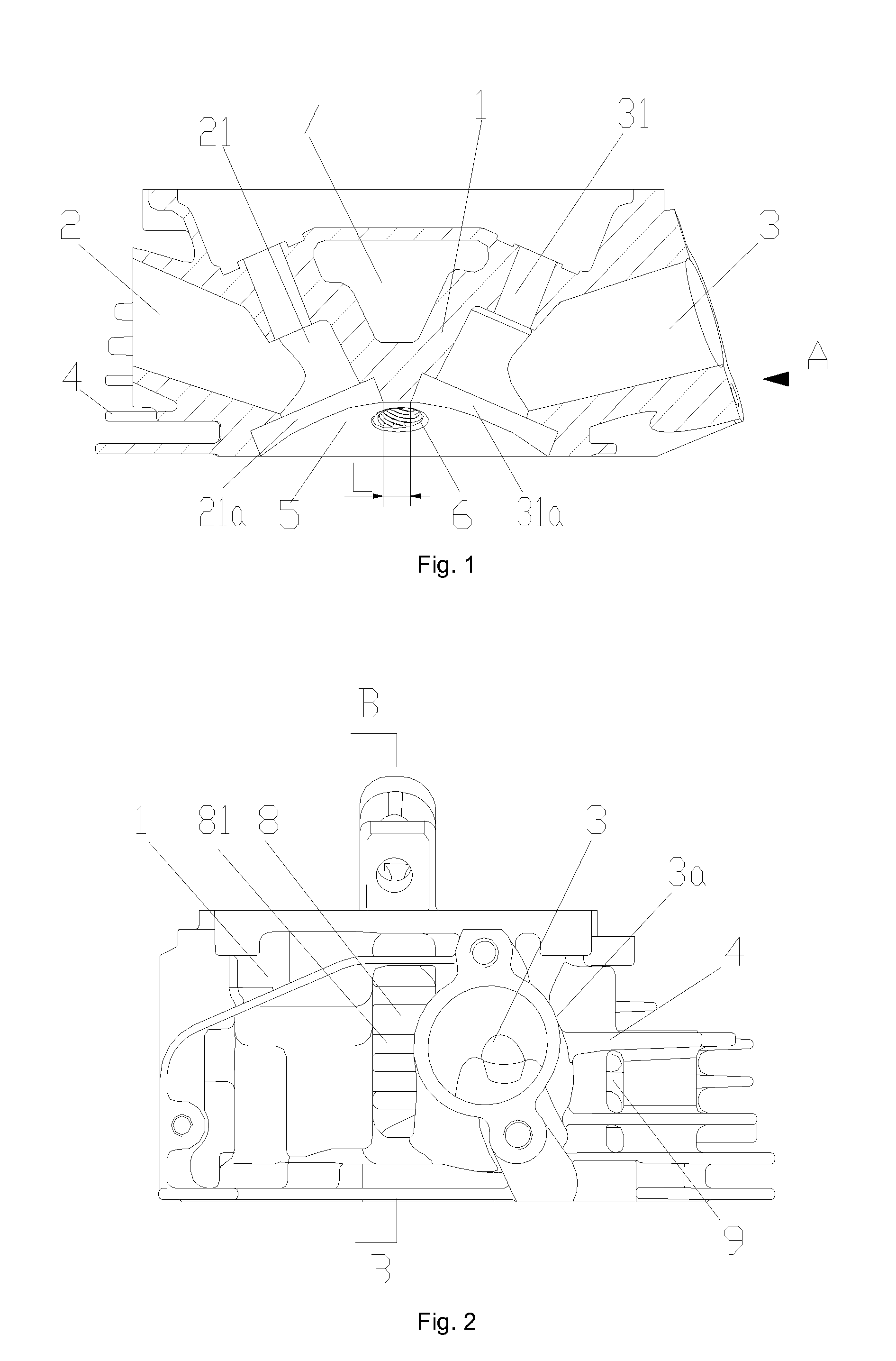

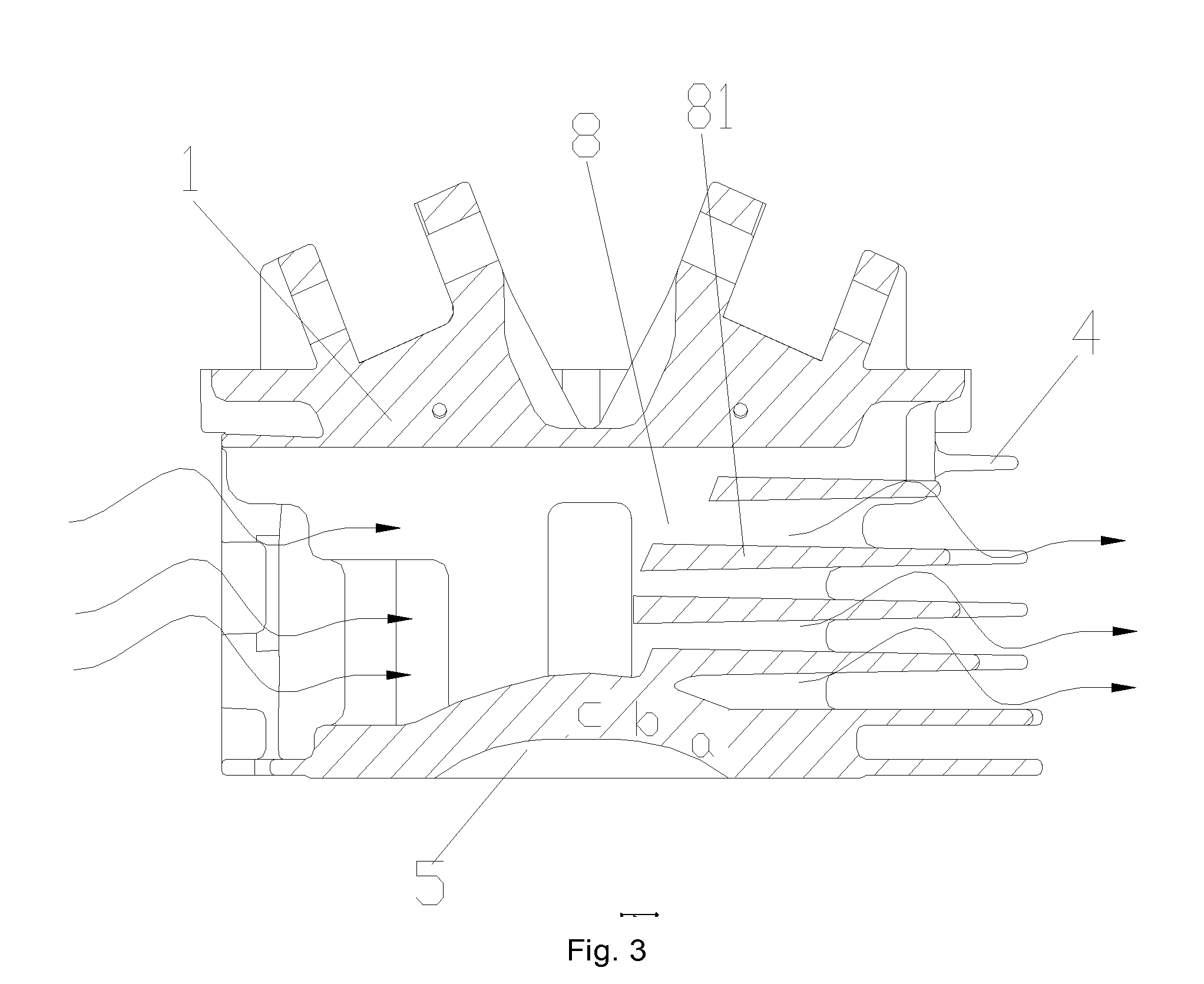

[0028]FIG. 1 shows a structure view of the invention, FIG. 2 shows a view of FIG. 1 along the direction A, FIG. 3 shows the view of FIG. 2 along the direction B-B, FIG. 4 shows a front view of the spark plug air-cooling passage, FIG. 5 shows a mounting structure view of rocker arms, and FIG. 6 shows a sectional view of the coordination between rocker arm shafts and rocker arm bases. As shown in the drawings: the air-cooling cylinder head of a gasoline engine in the embodiment comprises a cylinder head main body 1, and an intake passage 3, an exhaust passage 2 and a spark plug mounting hole 6 arranged in the cylinder head main body 1, a plurality of cooling fins 4 is arranged on the outer surface of the cylinder head main body 1, a combustion chamber surface 5 is formed on the inner side of the cylinder head main body 1, a longitudinally through air-cooling passage I 8 is arranged on the same side of the cylinder head main body 1 as the intake passage 3 and the exhaust passage 2, a t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com