Power transmission device

a technology of power transmission device and transmission device, which is applied in the direction of wind energy generation, liquid fuel engine components, dynamo-electric brakes/clutches, etc., can solve the problems of limited installation of power transmission device, hardly has a long service life, and noise and vibration, and achieves a wide range of acceleration and deceleration. , the effect of greater allowable torqu

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

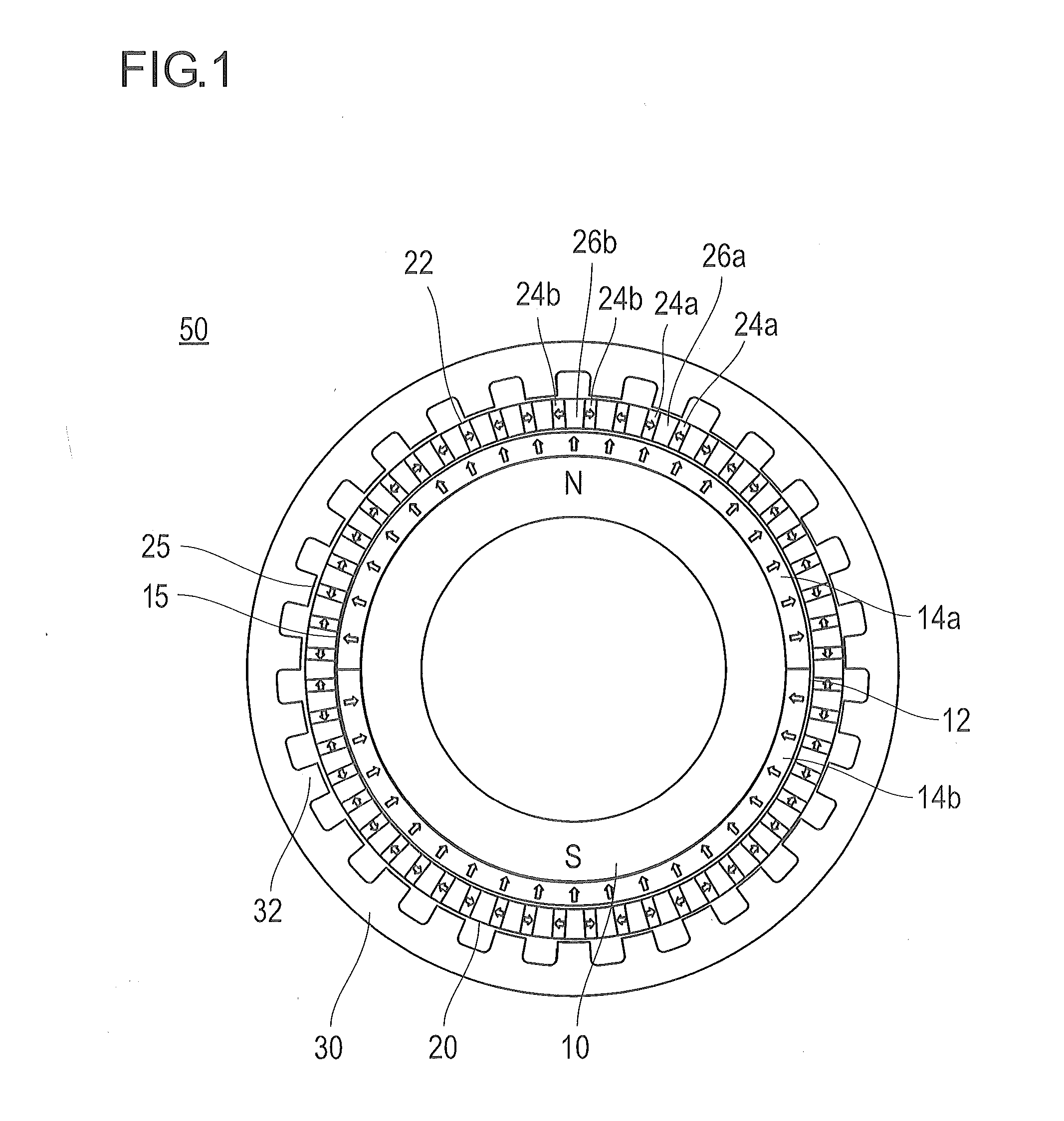

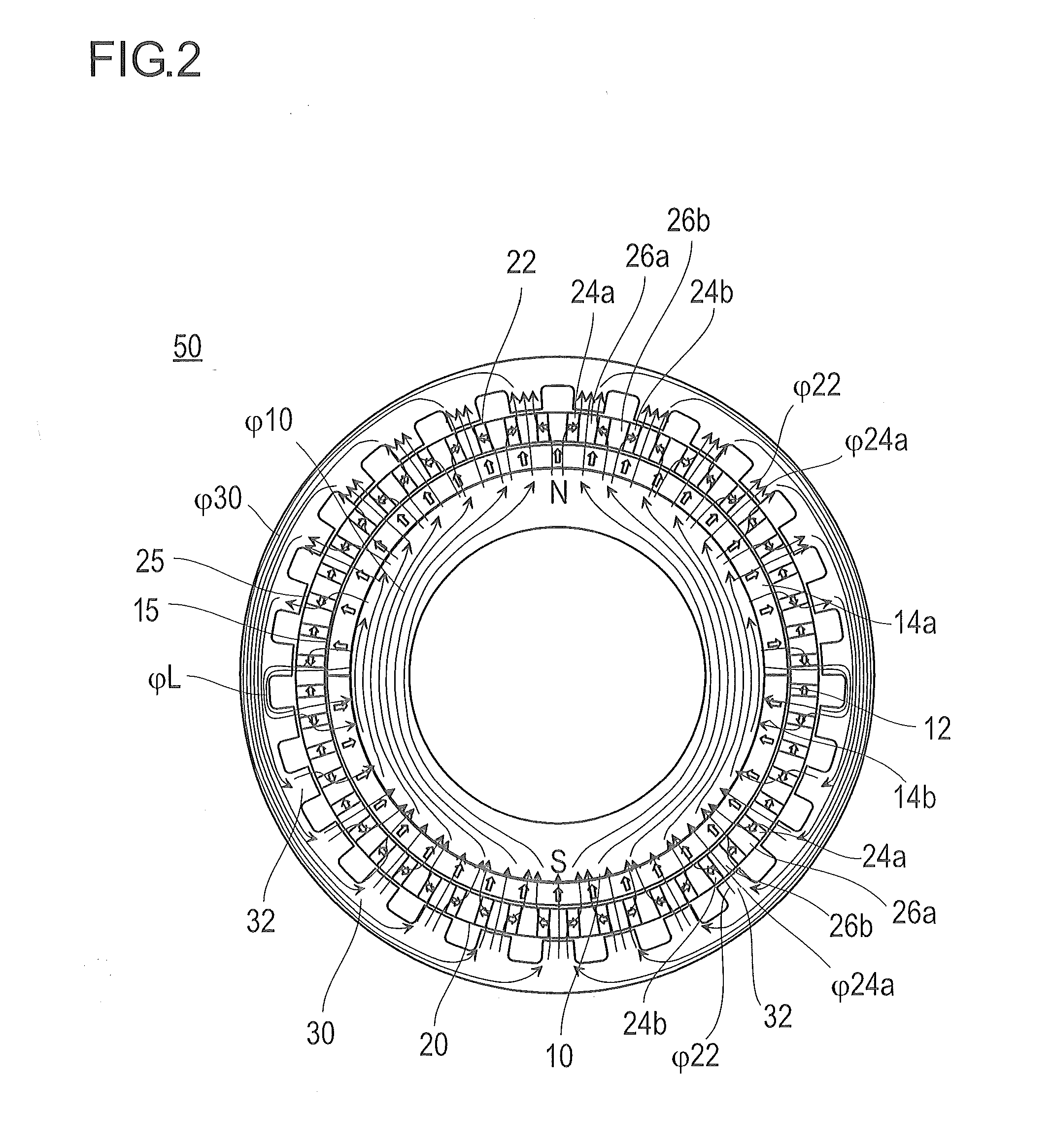

[0053]FIG. 1 is a configuration diagram of a power transmission device according to the first embodiment. FIG. 2 is an explanatory view of closed magnetic fields formed in the power transmission device in FIG. 1. FIG. 3 is an explanatory view of power transmission of the power transmission device. FIGS. 4 to 6 are explanatory views of a mechanism of power transmission of the power transmission device in FIG. 1. Hereinafter, a configuration and an operation of the power transmission device according to the present embodiment will be described.

[0054]

[0055]FIG. 1 is a configuration diagram of the power transmission device according to the present embodiment, and illustrates a cross section obtained by cutting the power transmission device in a direction orthogonal to a rotation axis direction of the power transmission device. In addition, directions of arrows illustrated in FIG. 1 are magnetizing directions of permanent magnets, and arrow directions of the arrows indicate the N pole an...

second embodiment

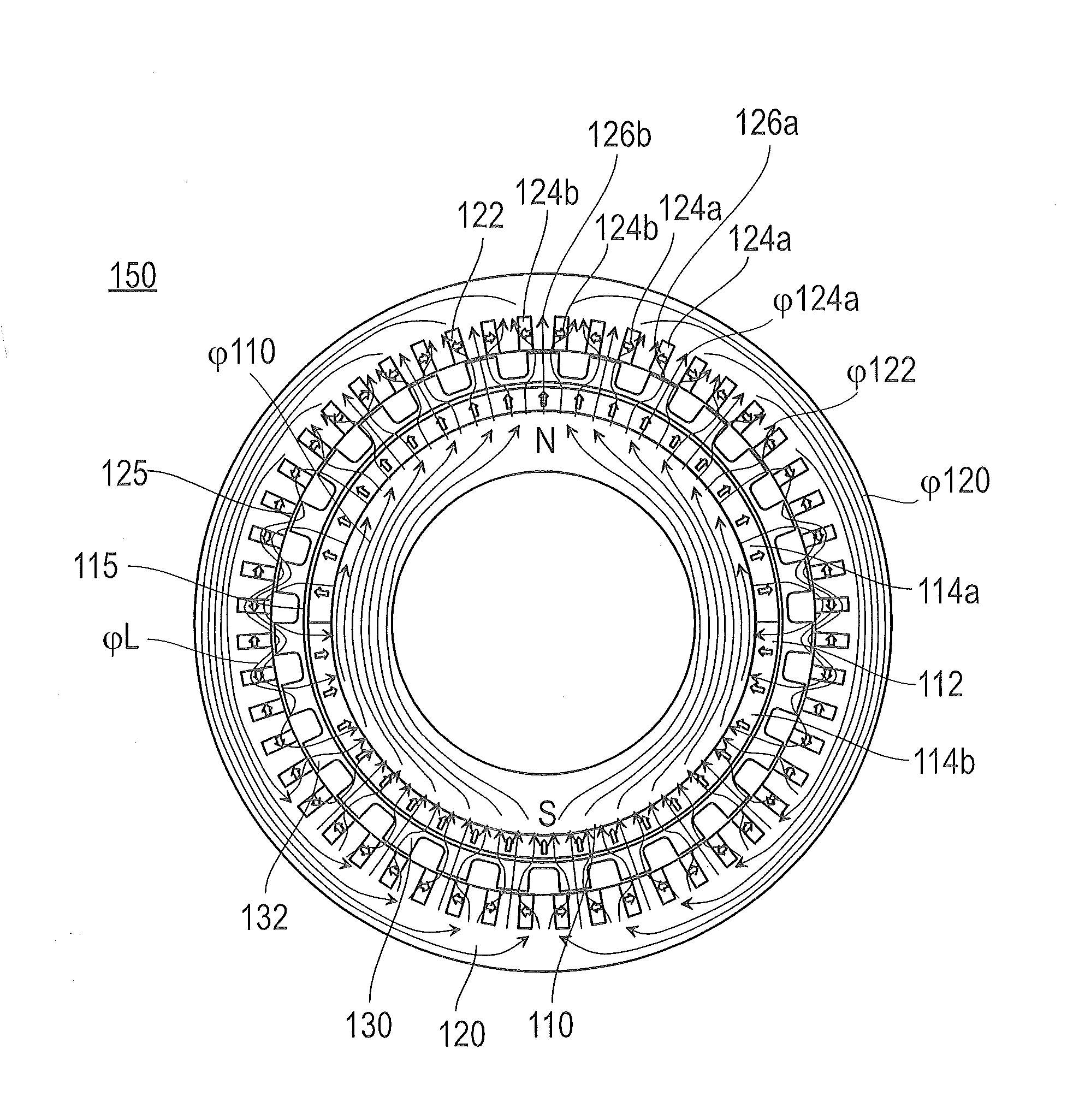

[0133]Next, a power transmission device according to the second embodiment will be described. FIG. 7 is a configuration diagram of the power transmission device according to the second embodiment. FIG. 8 is an explanatory view of closed magnetic fields formed in the power transmission device in FIG. 7.

[0134]As illustrated in FIG. 7, a power transmission device 150 according to the second embodiment differs from a power transmission device 50 according to the first embodiment in switching positions of a low speed magnet rotor and an inductor rotor.

[0135]

[0136]The power transmission device 150 includes a high speed magnet rotor 110, a low speed magnet rotor 120 and an inductor rotor 130. The high speed magnet rotor 110, the low speed magnet rotor 120 and the inductor rotor 130 are concentrically arranged. In the present embodiment, the high speed magnet rotor 110 of the smallest diameter is arranged on an innermost side, and the low speed magnet rotor 120 of the largest diameter is ar...

third embodiment

[0153]Next, a power transmission device according to the third embodiment will be described. FIG. 9 is a configuration diagram of the power transmission device according to the third embodiment.

[0154]As illustrated in FIG. 9, a power transmission device 250 according to the third embodiment differs from a power transmission device 50 according to the first embodiment in switching positions of a high speed magnet rotor and an inductor rotor.

[0155]

[0156]The power transmission device 250 includes a high speed magnet rotor 210, a low speed magnet rotor 220 and an inductor rotor 230. The high speed magnet rotor 210, the low speed magnet rotor 220 and the inductor rotor 230 are concentrically arranged. In the present embodiment, the inductor rotor 230 of the smallest diameter is arranged on an innermost side, and the high speed magnet rotor 210 of the largest diameter is arranged on an outermost side. The low speed magnet rotor 220 is arranged between the high speed magnet rotor 210 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com