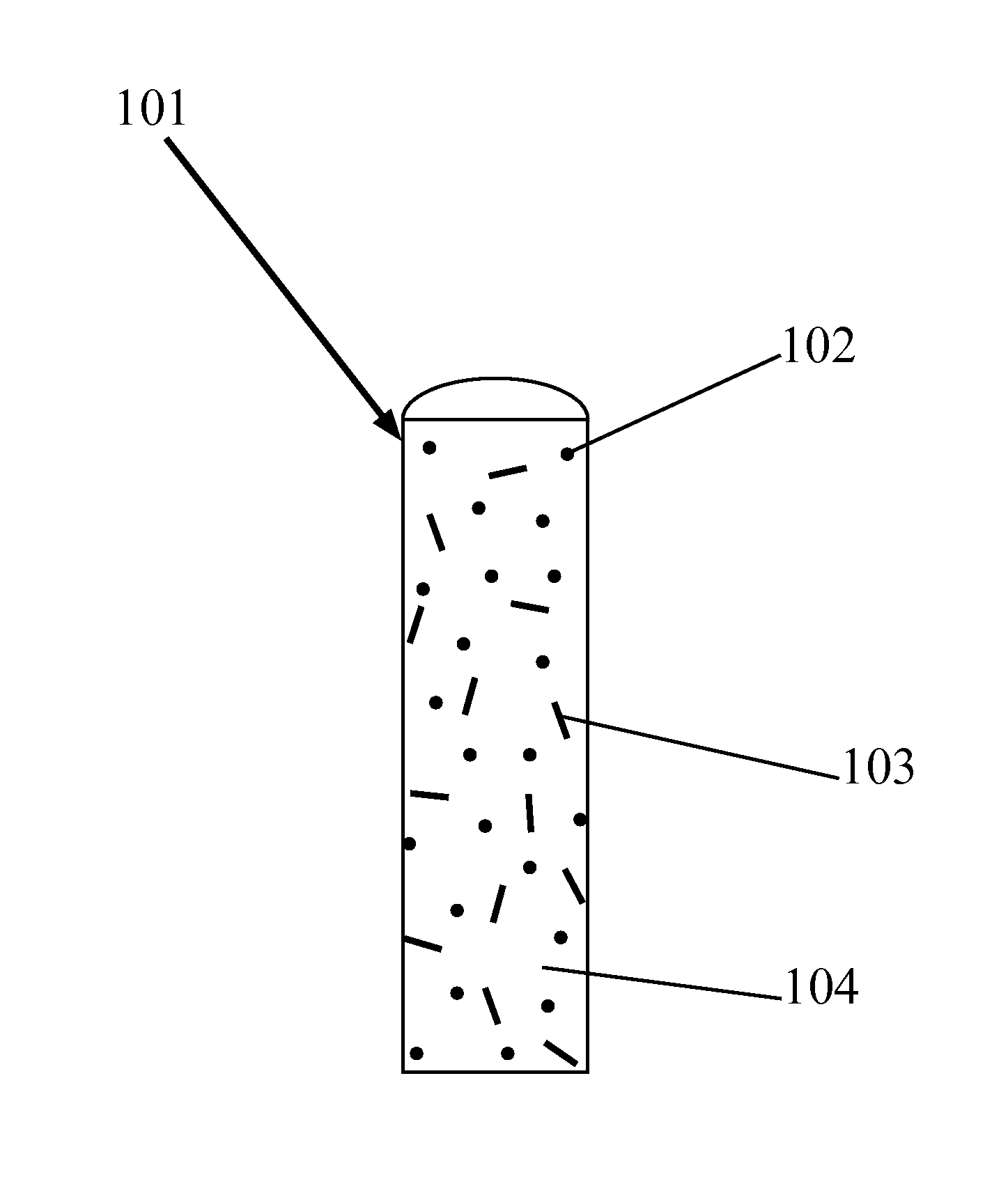

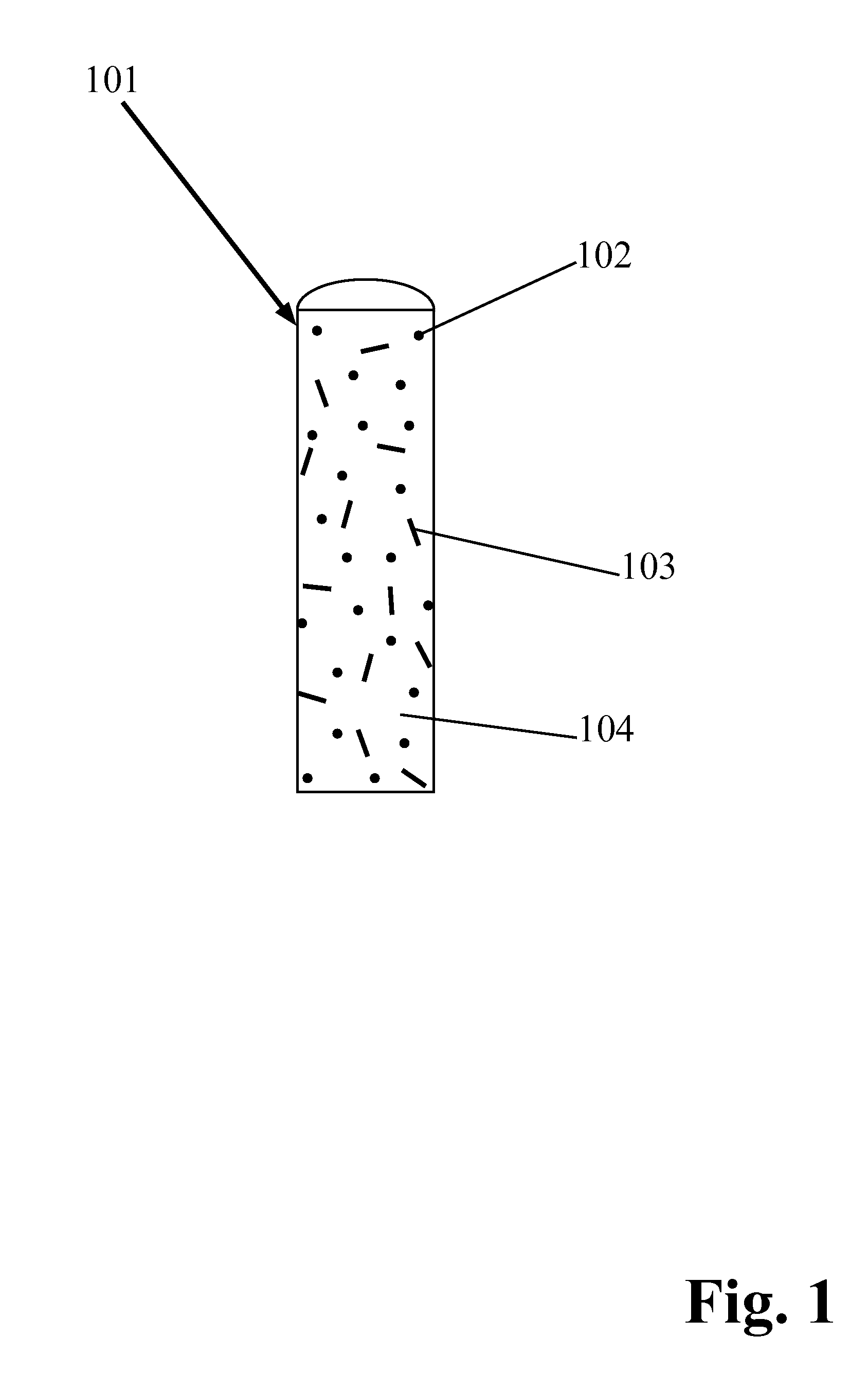

Firestarter using Diatomaceous Earth and Organic Fibers

a technology of organic fibers and diatomaceous earth, which is applied in the direction of biofuels, waste based fuels, fuels, etc., can solve the problems of increased manufacturing costs, labor costs, and increased manufacturing costs of firelogs, so as to facilitate preliminary ignition and continued burning, increase the surface area of firelogs and their overall flammability, and promote initial and flammability. the effect of flammability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021]The artificial firestarter of this present invention may provide for a more economical method of production of firestarter by replacing dense non absorbent cell matter of a firestarter with long organic fiber. The replacement of dense non absorbent cell matter, either in full or in part, will allow for an equivalent energy content, but result in a product that is much more compactable and reduce the stress on machinery. The components firestarter of this present invention may include those components of a traditional firelog: combustible cell material, wax or oil or fat based binding material and non absorbent combustible cell material to meet the objectives of this present invention.

[0022]Replacing, either fully or in part, the non absorbent cell matter of a firelog with organic fibers will allow for a product that is much easier to manufacture since organic fibers are much less dense than common non absorbent cellulosic matter including: pistachio nut shells, walnut shells, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| combustible cellulosic | aaaaa | aaaaa |

| flammable | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com