Processes for Purifying a Cellulosic Material

a cellulosic material and purification technology, applied in pulp by-product recovery, pulp liquor regeneration, papermaking, etc., can solve the problems of high cost of such pulps, incompatible with certain industrial uses, and inability to commercialize dmdo, so as to reduce the content of hemicellulos

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

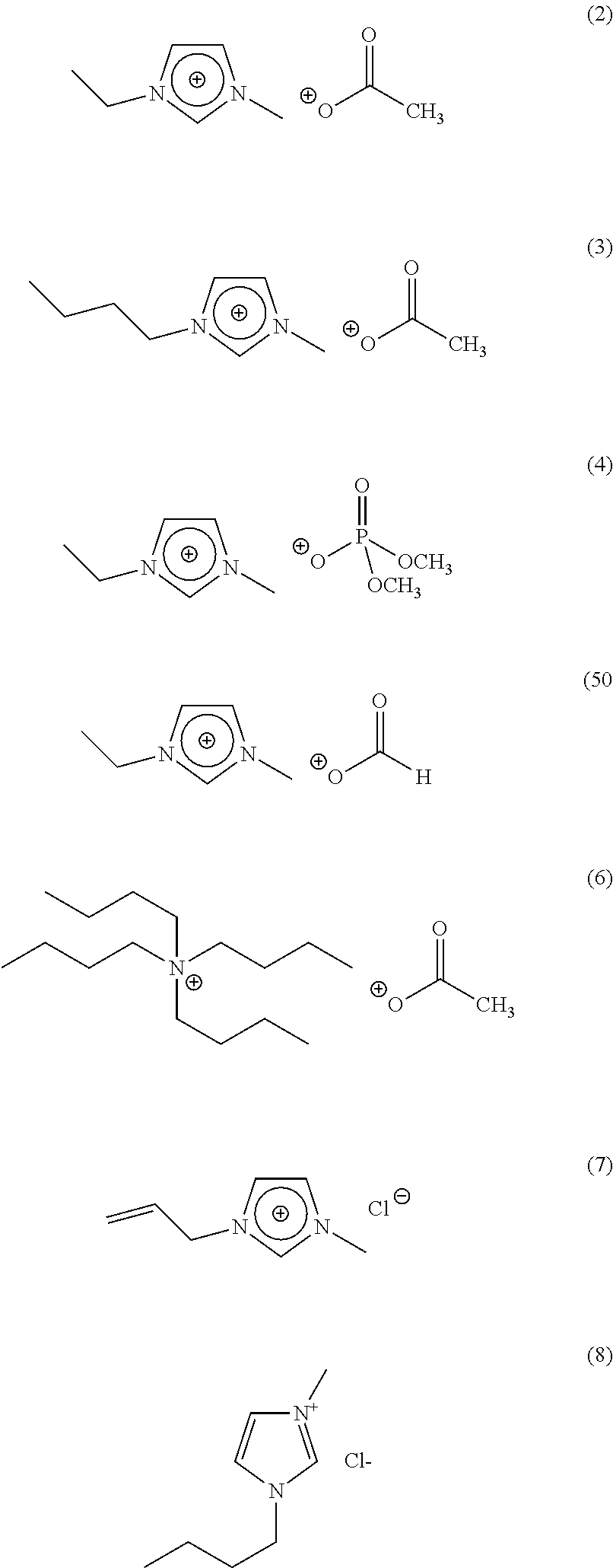

[0106]A cellulosic material comprising 74.8 wt. % cellulose, 18.7 wt. % hemicellulose and 6.5 wt. % water was fed to an extraction unit. Separately, an extractant comprising 3.5 wt. % EMIM Ac and 96.5 wt. % DMSO was fed to the extraction unit. The extraction was conducted at a temperature of 90-110° C. and a pressure of 90−110 kPa. An extraction mixture comprising 3.6 wt. % cellulose, 0.89 wt. % hemicellulose, 0.31 wt. % water, 3.3 wt. % ionic liquid and 91.9 wt. % DMSO was removed from the extractor and sent through a vacuum filter and washed with an extractant wash to remove an extraction filtrate comprising extractant and hemicellulose. The extractant wash was water and was fed at a 10:1 mass ratio of water to pulp. The washed cellulosic material, e.g., the intermediate cellulosic material, comprised 24.5 wt. % cellulose, 0.5 wt. % hemicellulose and 75 wt. % water. The intermediate cellulosic product was then de-liquored to concentrate the intermediate cellulosic product. The res...

example 2

[0109]The finished cellulosic product and the finished hemicellulose product were prepared as in Example 1, except that the extraction process was completed in a 2-stage counter-current operation. The extraction time was dropped to 60 minutes at temperature of 90° C. for dissolving the same amount of hemicellulose, which was indicated by the UV absorbance value of 1.2 at 277 nm wavelength, or equivalently 2.8 wt. % hemicellulose.

example 3

[0110]The finished cellulosic product and the finished hemicellulose product were prepared as in Example 1, except that the extractant wash comprised 90 wt. % acetic acid and 10 wt. % water. The value of UV absorbance at 277 nm for the final pulp is 0.98, or equivalently 1.9 wt % hemicellulose.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wt. % | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com