Combined biological hydrogen production method by adopting sludge and fibers of recovered waste paper

A technology of waste paper fiber and biological hydrogen production, which is applied in the direction of biofuel, fermentation, etc., can solve the problems of waste of resources and energy, few utilization methods, and a huge amount of recycled waste paper fiber, etc., and achieves easy hydrolysis and fermentation, major economic Effects of Value and Social Meaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

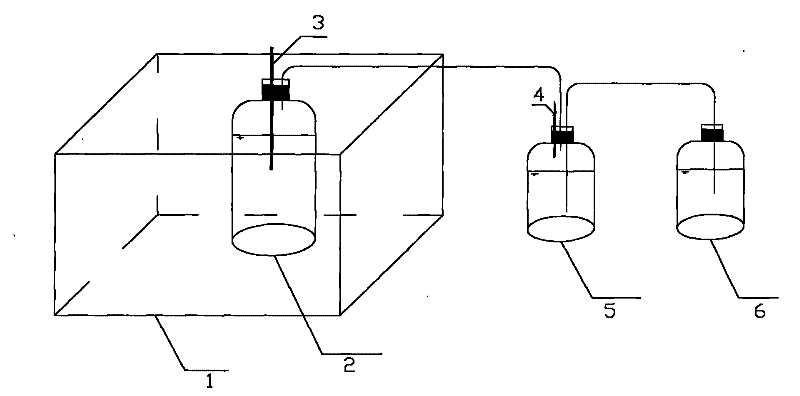

Method used

Image

Examples

example 1

[0023] Put 200mL of anaerobic sludge into the biological hydrogen production reactor, add distilled water to make it up to 1L, mix well, adjust the initial pH value to 7.0 with 1mol / L HCl solution, fill the hydrogen production reactor with nitrogen for 15s, and seal the hydrogen production reactor. fermentation reaction. Control the reaction temperature of the constant temperature shaker to 35°C, and the shaker speed to 80r / min. After 12 days of reaction, 27mL of gas is obtained. After sampling from the gas sampling port, it is absorbed by dilute NaOH lye, and all of them are CO 2 , without H 2 produce.

example 2

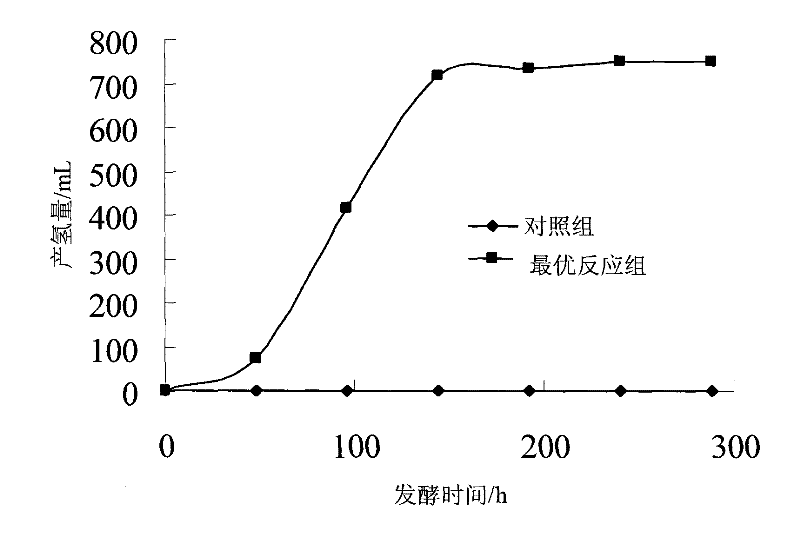

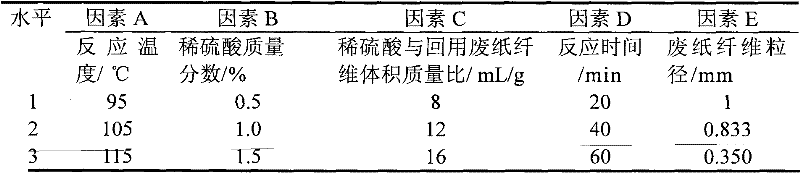

[0025] Take 20g of recycled waste paper fiber to carry out the orthogonal test of dilute sulfuric acid hydrolysis pretreatment, get the hydrolyzate and the recycled waste paper fiber after hydrolysis, the waste paper fiber composition is: cellulose 64.8%, hemicellulose 7.70%, ash content 5.51% , moisture content 9.06%. The recycled waste paper fibers after hydrolysis were washed with distilled water to neutrality, and mixed with 200ml of anaerobic sludge and 800ml of distilled water. The sludge was taken from a sewage plant. The total solid content (TS) of the sludge was 88.9%, and the volatile solid content (VS) 87.5%, VS / TS 98.4%, pH 7.41. The hydrolysis conditions of dilute sulfuric acid pretreatment take five factors: reaction temperature, mass fraction of dilute sulfuric acid, volume-to-mass ratio of dilute sulfuric acid to recycled waste paper fiber, reaction time, and particle size of waste paper fiber. Each factor has three levels. Orthogonal test factor levels are sh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com