Device for confining Bumblebees, use of a laminate material for confining bumblebees and method for confining bumblebees

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

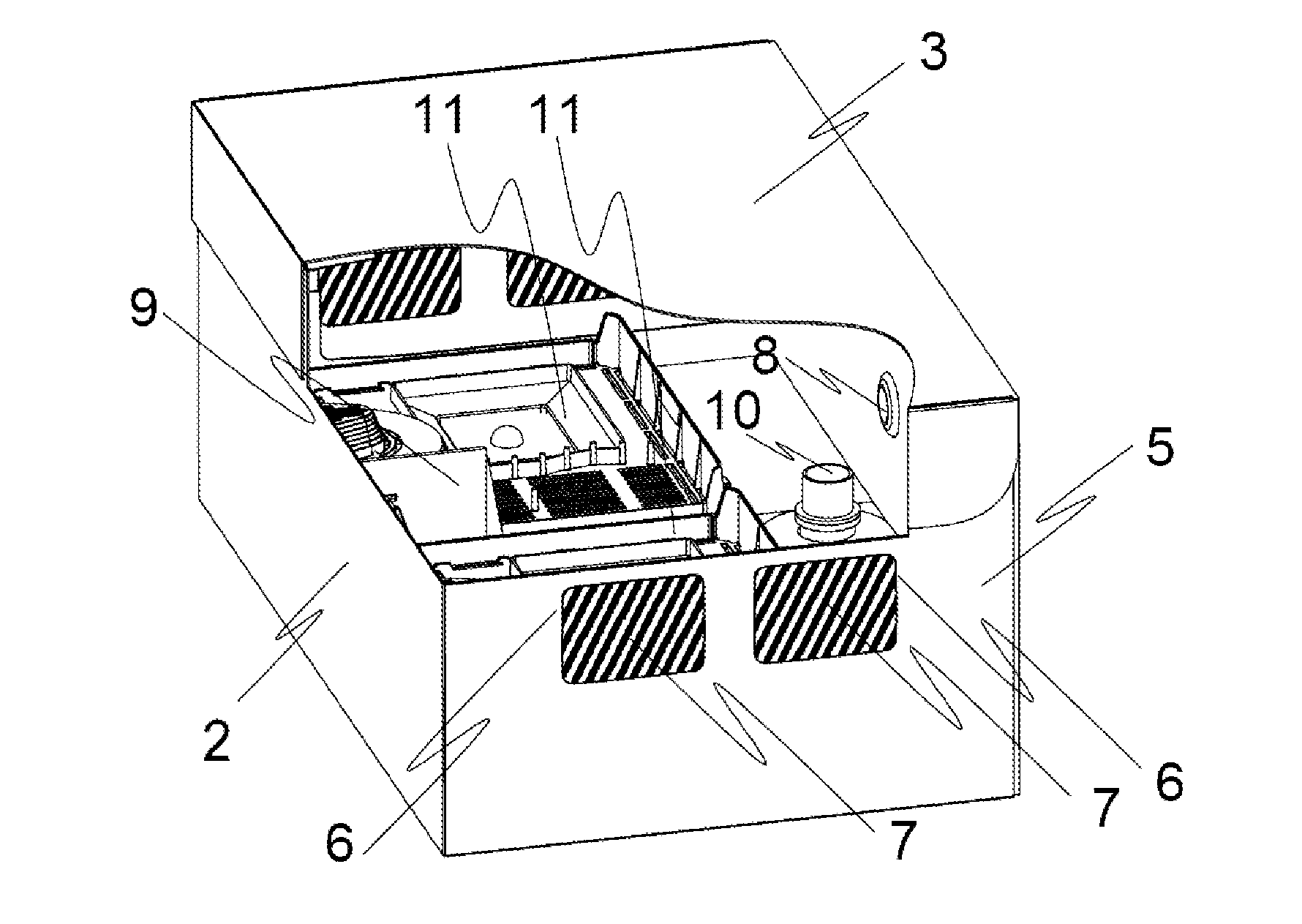

Image

Examples

experiment 1a

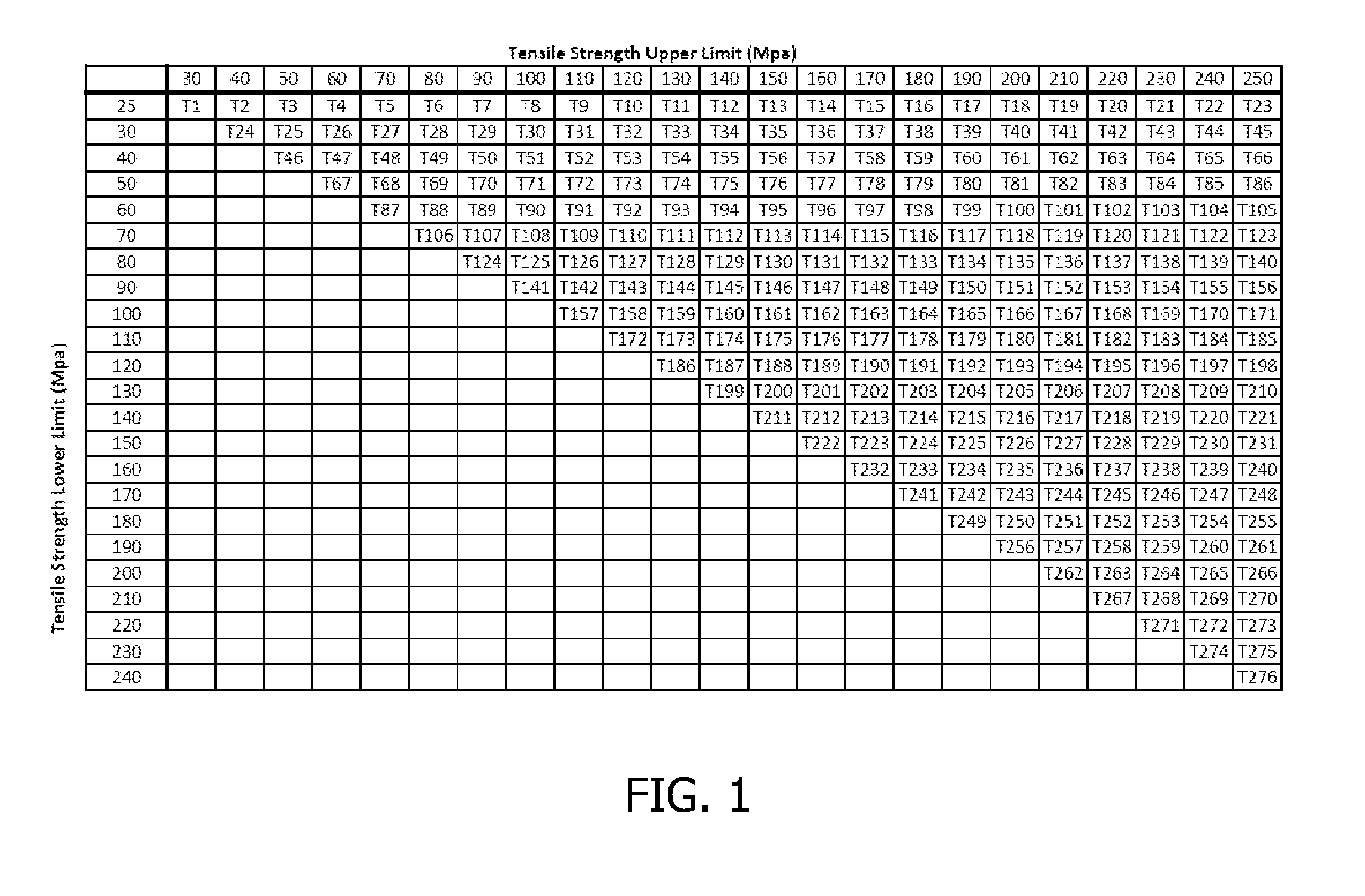

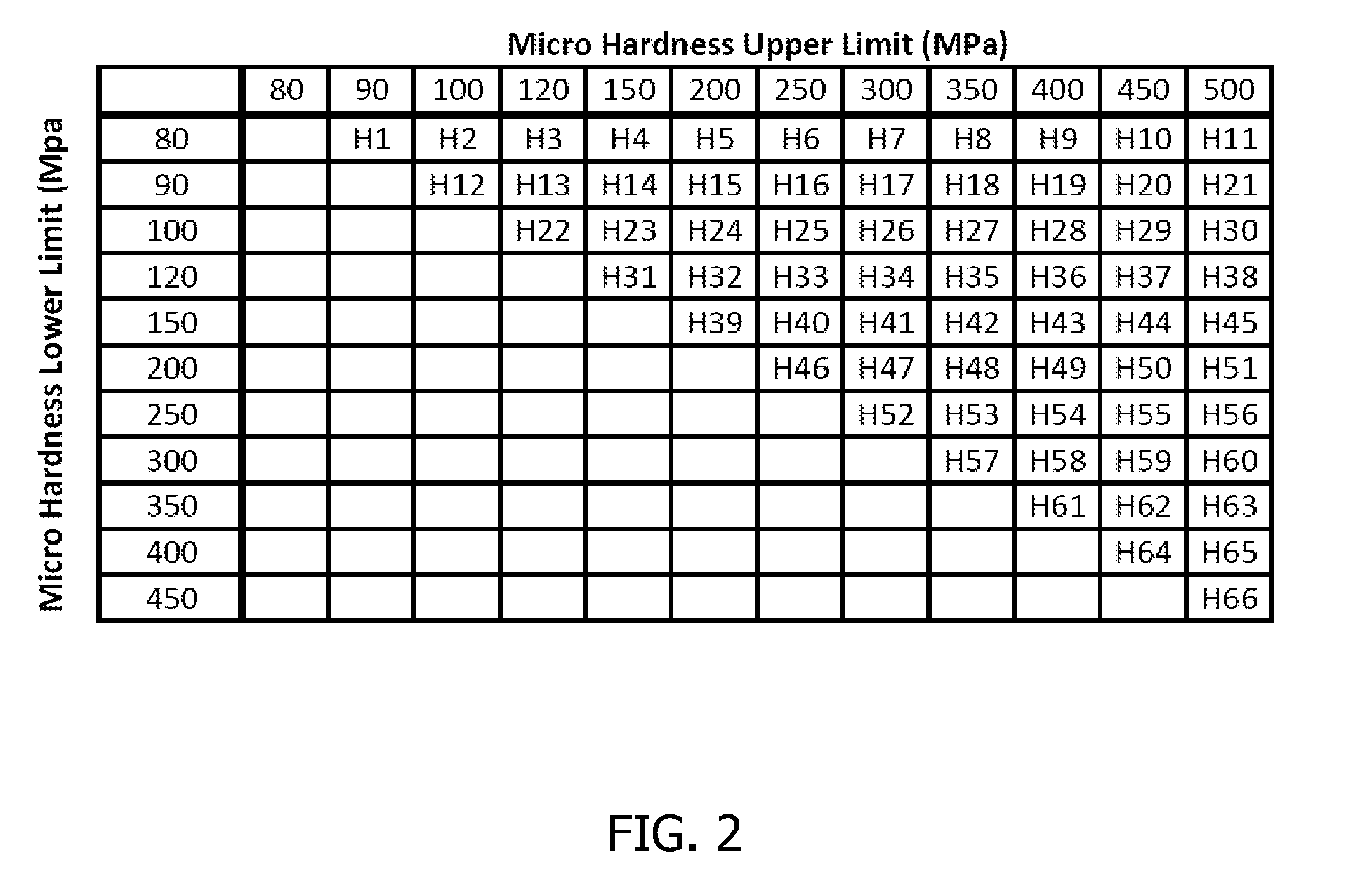

PET Coated Paperboard

[0051]The laminate consists of the paperboard with a layer of 12 μm PET coated on each side. PET is a polymer having a reported tensile strength of around 172 MPa and a micro hardness of around 200 MPa. The test batch contained 2 hives, of which 0 showed critical damage 14 days after placing the bumblebees in the enclosure. The visual inspection of the interior of the hives revealed no damage that could potentially progress to critical damage.

experiment 1b

OPP Coated Paperboard

[0052]The laminate consists of the said paperboard with a layer of 80 μm OPP coated on each side. OPP is a polymer having a reported tensile strength of around 172-207 MPa and a micro hardness of around 80 MPa. The test batch contained 2 hives, of which 0 showed critical damage 14 days after placing the bumblebees in the enclosure. The visual inspection of the interior of the hives revealed no damage that could potentially progress to critical damage.

experiment 1c (comparative)

PE Coated Paperboard

[0053]The laminate consists of the paperboard with a layer of 12 μm PE coated on each side. PE is a polymer having a reported tensile strength of about 8.3 to 17.2 MPa and a micro hardness of around 25 MPa.

[0054]The test batch contained 2 hives, of which 2 showed critical damage in a top corner two days after placing the bumblebees in the enclosure. The visual inspection of the interior of the hives showed that besides the critical damage, adjacent to the aluminum tape the laminate of the corners was removed over the length of the aluminum tape.

[0055]The tests show the secure bumblebee confinement in exemplary embodiments of the invention over a period of up to 14 days. In view of the absence of damage on the interior side of the hive that could potentially progress to critical damage, there is a justified confidence that by using the present invention secure bumblebee confinement can be maintained over longer periods of time. This was confirmed by further tests ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com