System and Method for Reducing Reactive Current on a Common DC Bus with Multiple Inverters

a reactive current and dc bus technology, applied in the direction of dc network circuit arrangement, two-wire dc circuit arrangement, etc., can solve the problems of high frequency switching generating undesirable reactive currents at carrier frequency and harmonics, significant increase in cost and potentially undesirable weight of the controlled system, and achieve the effect of reducing the total reactive current presen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

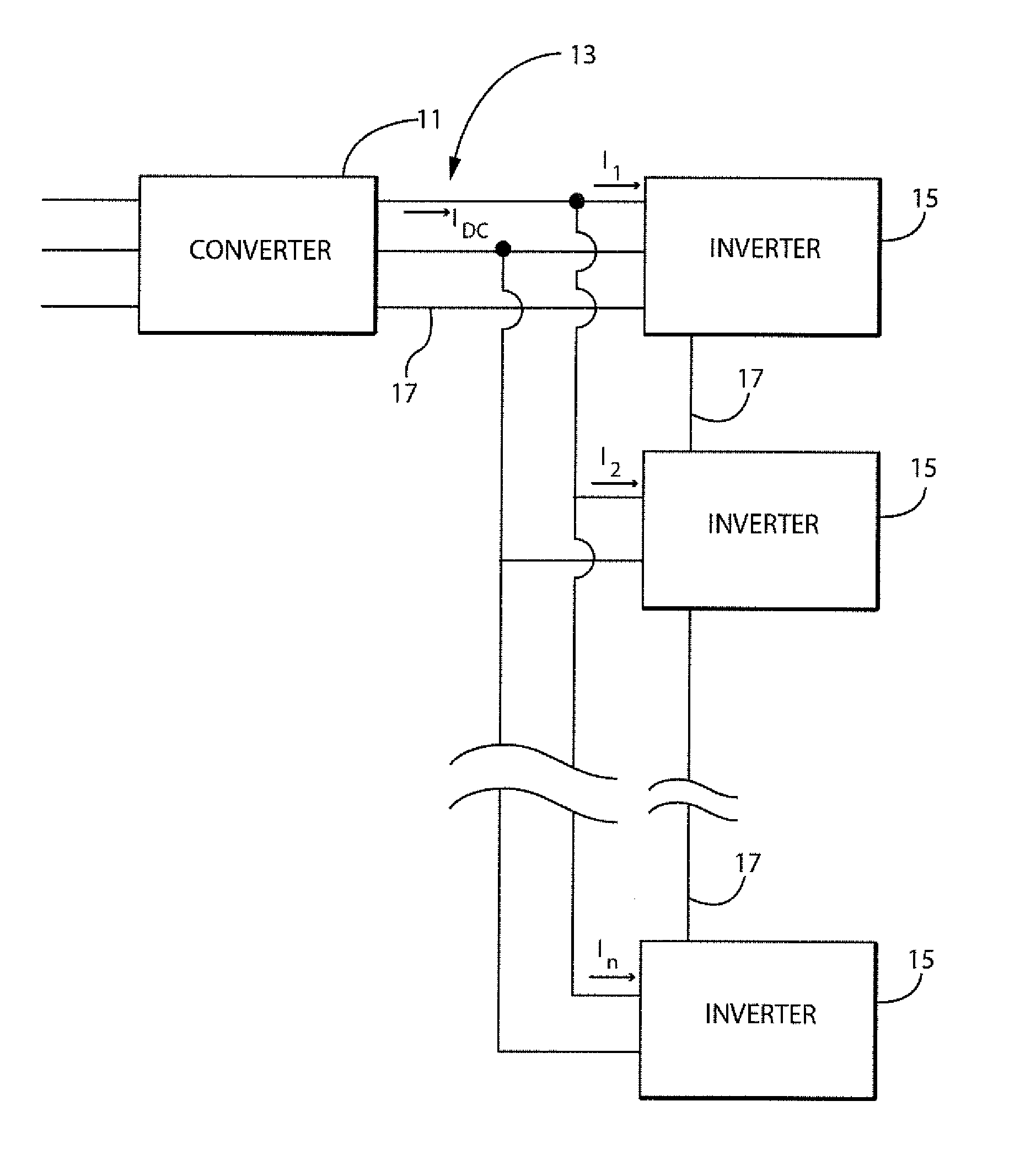

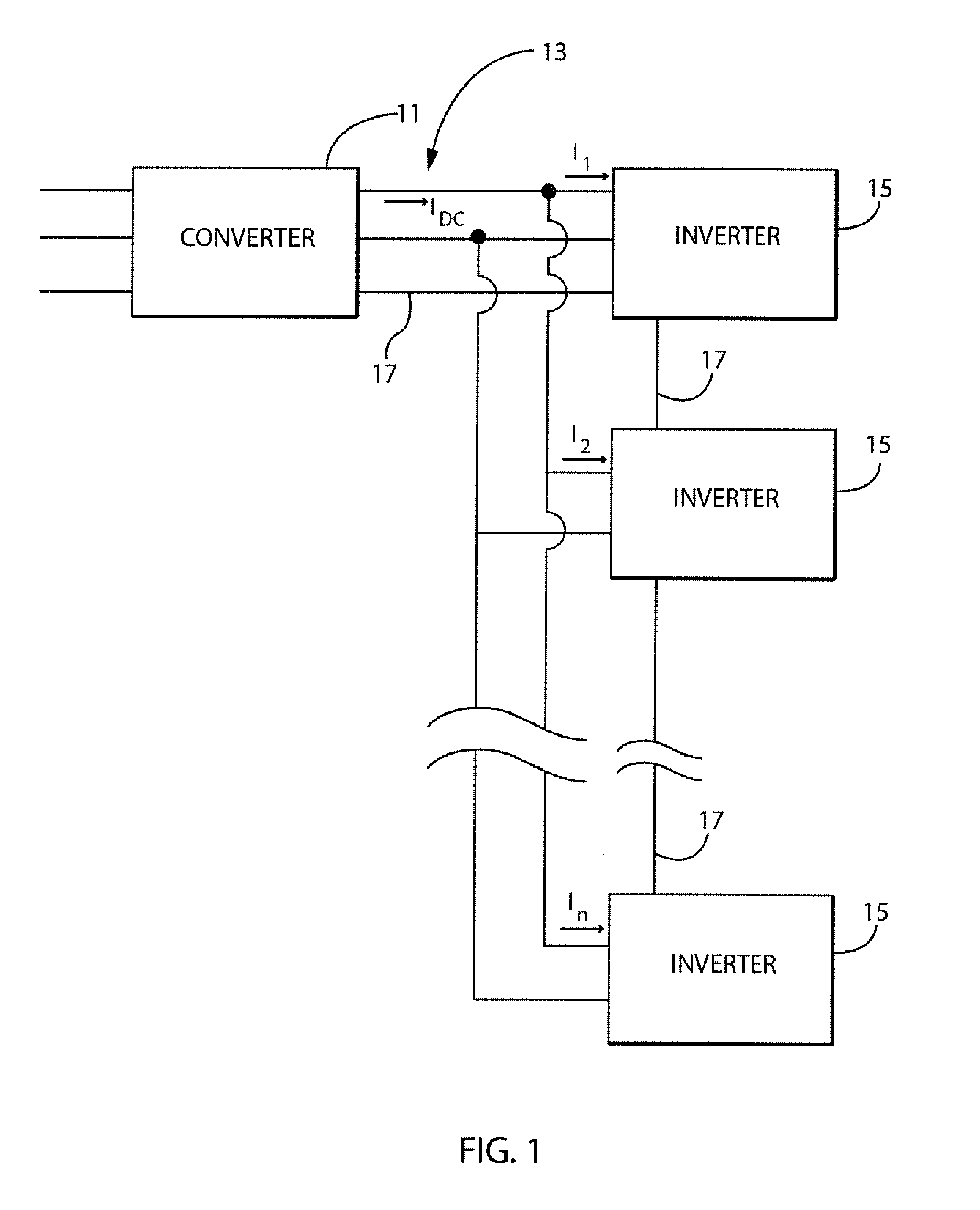

[0034]Turning initially to FIG. 1, a block diagram representation of a system including multiple inverters 15 connected to a single DC bus 13 is illustrated. According to the illustrated embodiment, a converter 11 receives power in a first form and provides it to the DC bus 13. The input may be a DC voltage or an AC voltage, where the AC voltage is either single phase or multi-phase. The converter 11 is configured to supply a regulated DC voltage on the DC bus 13. The system includes at least a first inverter 15 and a second inverter 15, but may include any number of additional inverters 15. Each inverter 15 converts the DC voltage present on the DC bus 13 to an AC voltage for use by an electrical load. Communication media 17 extends between the converter 11 and each inverter 15. The communication media 17 may be a single electrical conductor, multiple electrical conductors, a network cable configured to transmit data packets, or any other suitable communication media 17 configured ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com