Gas lift system for oil production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

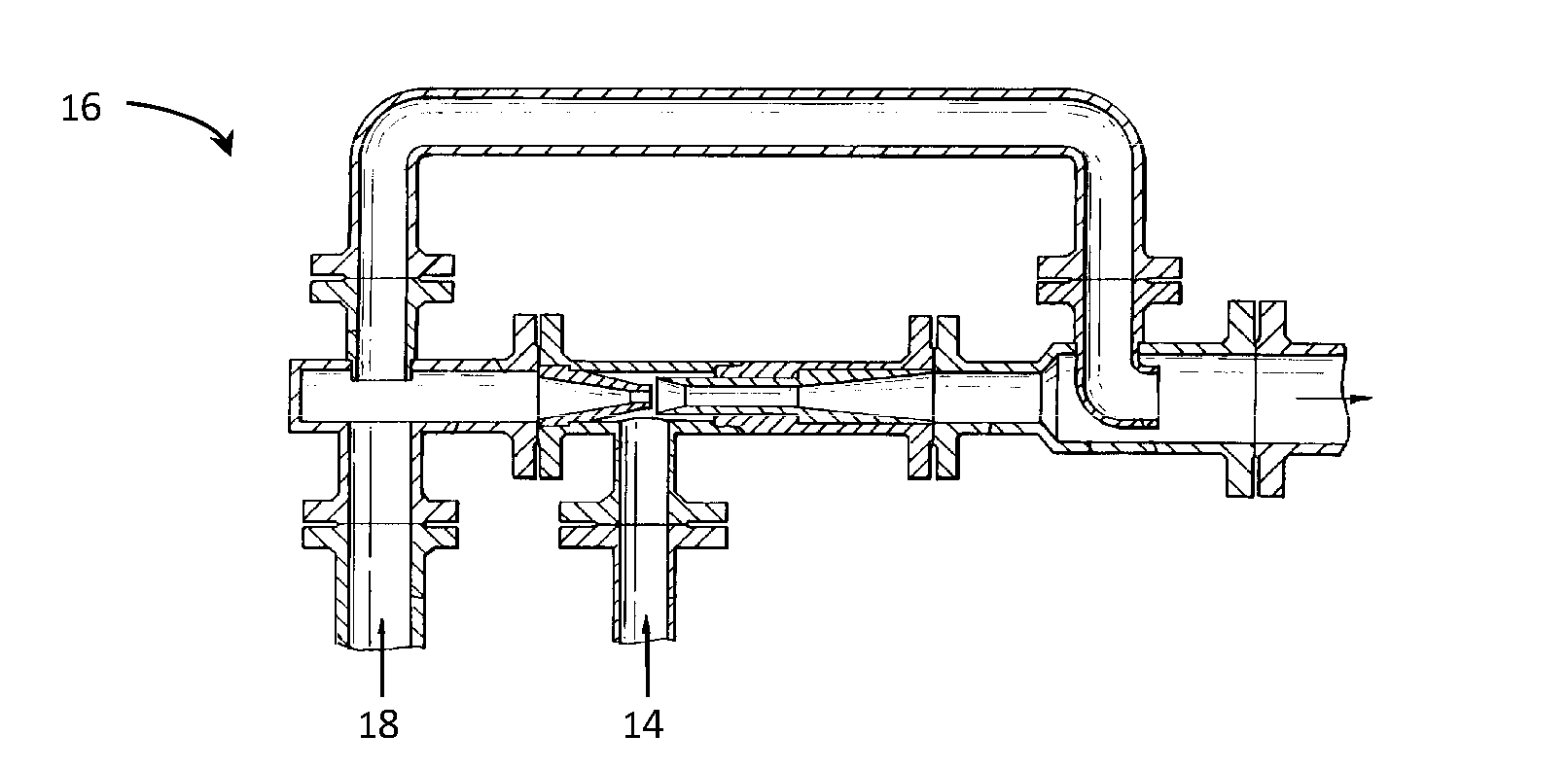

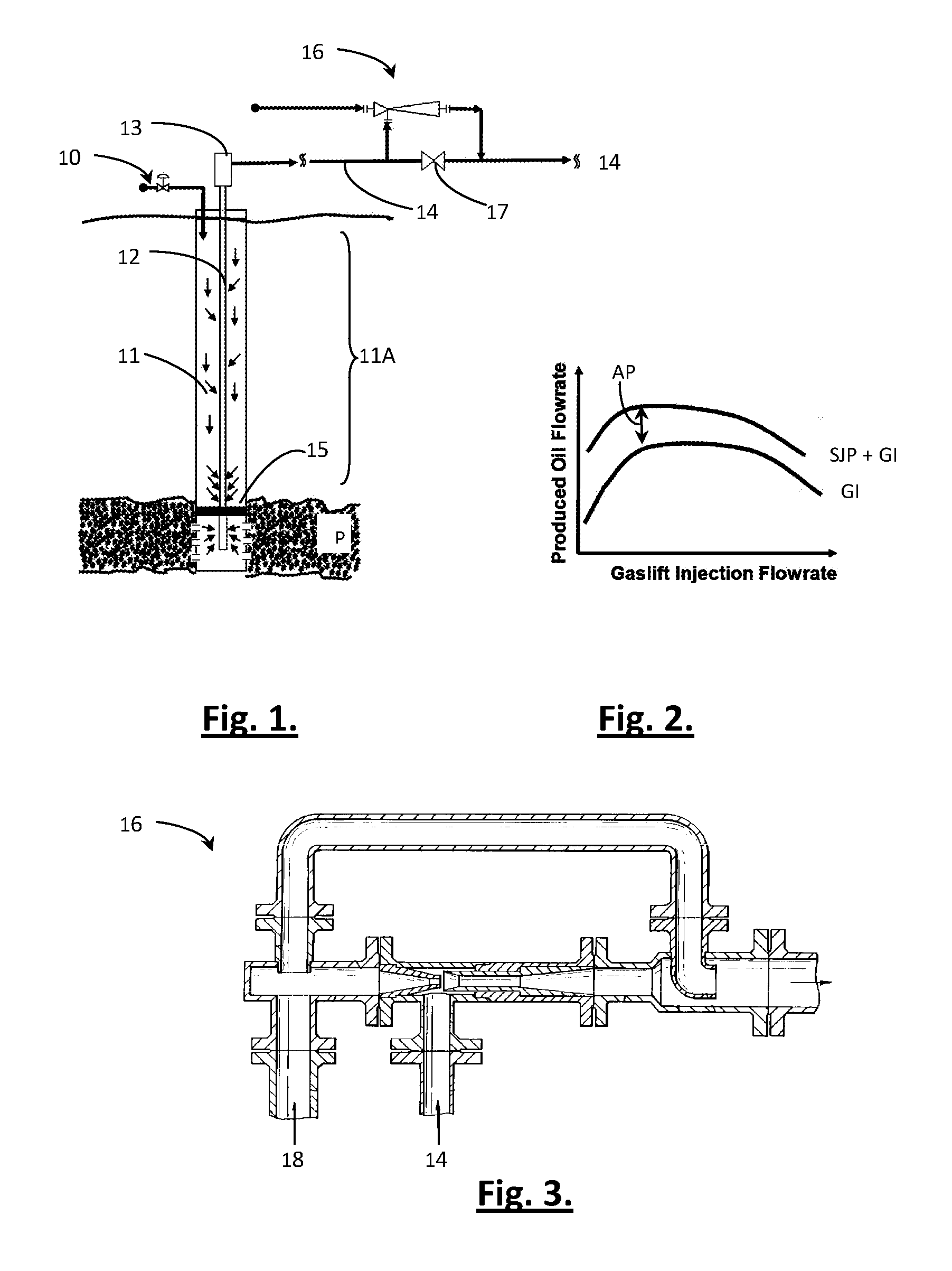

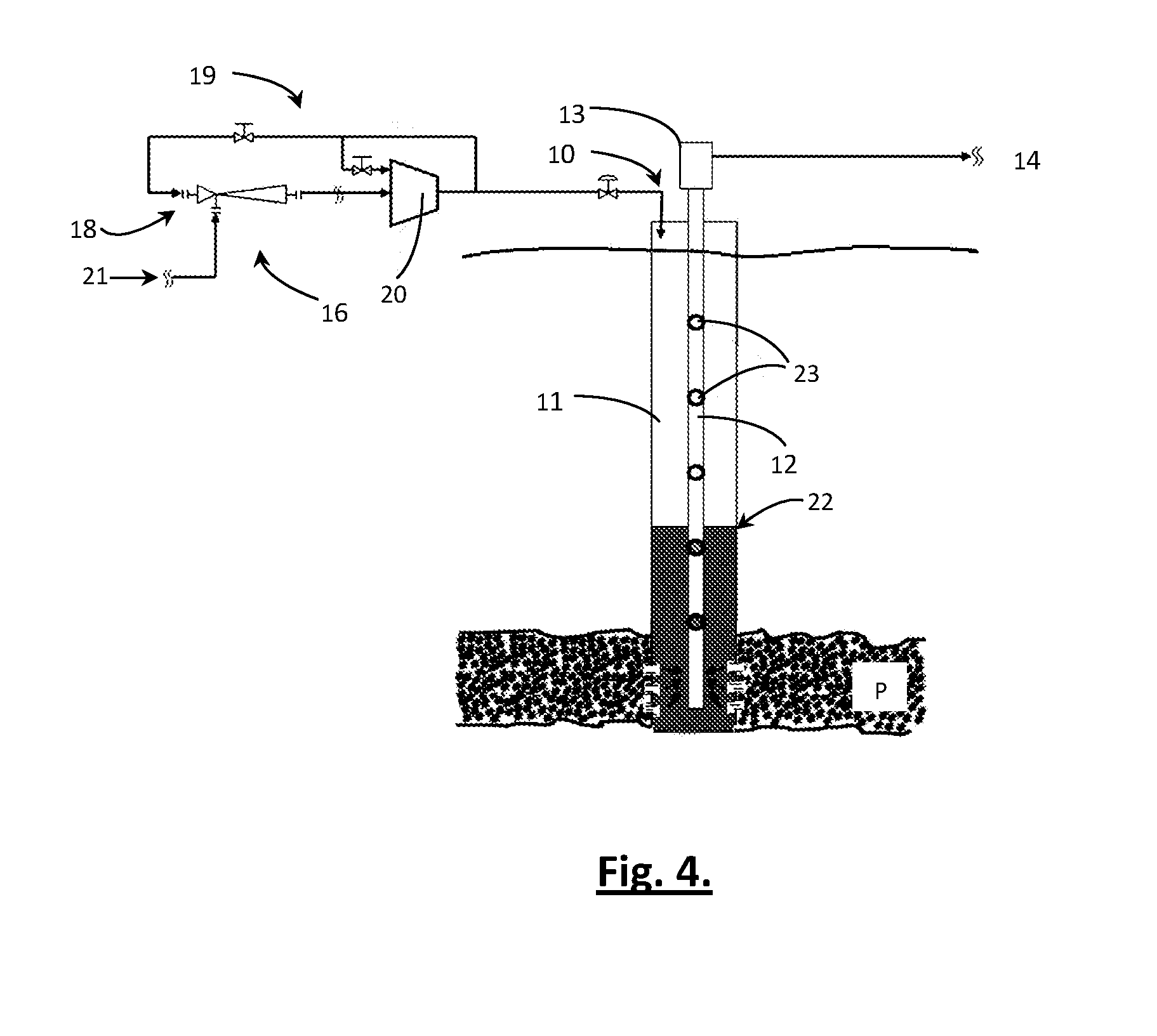

[0032]Referring to FIG. 1, increased oil production in a low GOR well is achieved by implementing a gas lift injection system 10 into a well 11 such that the hydrostatic head of fluids in the extraction tube 12 is reduced. An oil / gas mixture leaves the well head 13 for downstream processing via a pipeline 14.

[0033]According to known practice, a pressurized upper section 11A of the well 11 is sealed from the pay zone P by a barrier 15 (through which the tube 12 passes) and gas is introduced through the tube 12 wall at different depths via valves or apertures (not pictured in FIG. 1). The flow rate of fluid naturally rising through the tube 12 due to underground pressure in the pay zone P is increased by bubbles forming from the injected gas into the tube 12.

[0034]The gas lift system as described above is generally known; however, in many cases there may be an insufficient amount of lift gas available at the desired pressure to achieve the maximum or optimum level of reduction in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com