Layer heat exchanger for high temperatures

a heat exchanger and high temperature technology, applied in indirect heat exchangers, laminated elements, lighting and heating apparatus, etc., can solve the problems of thermal mechanical heat exchanger structure, outward tightness of heat exchanger, and tightness of layer blocks in the interior, so as to achieve sufficient internal tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

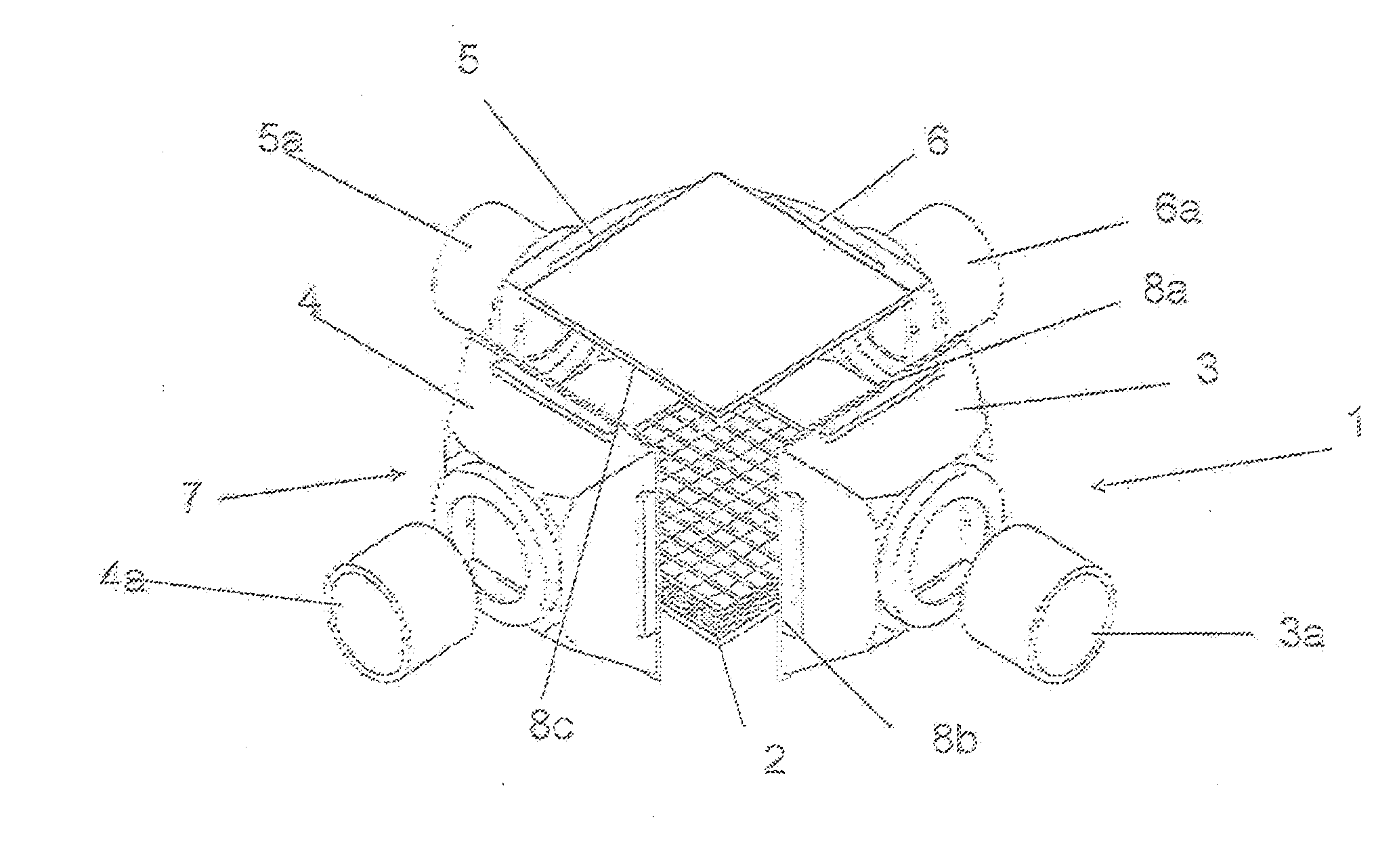

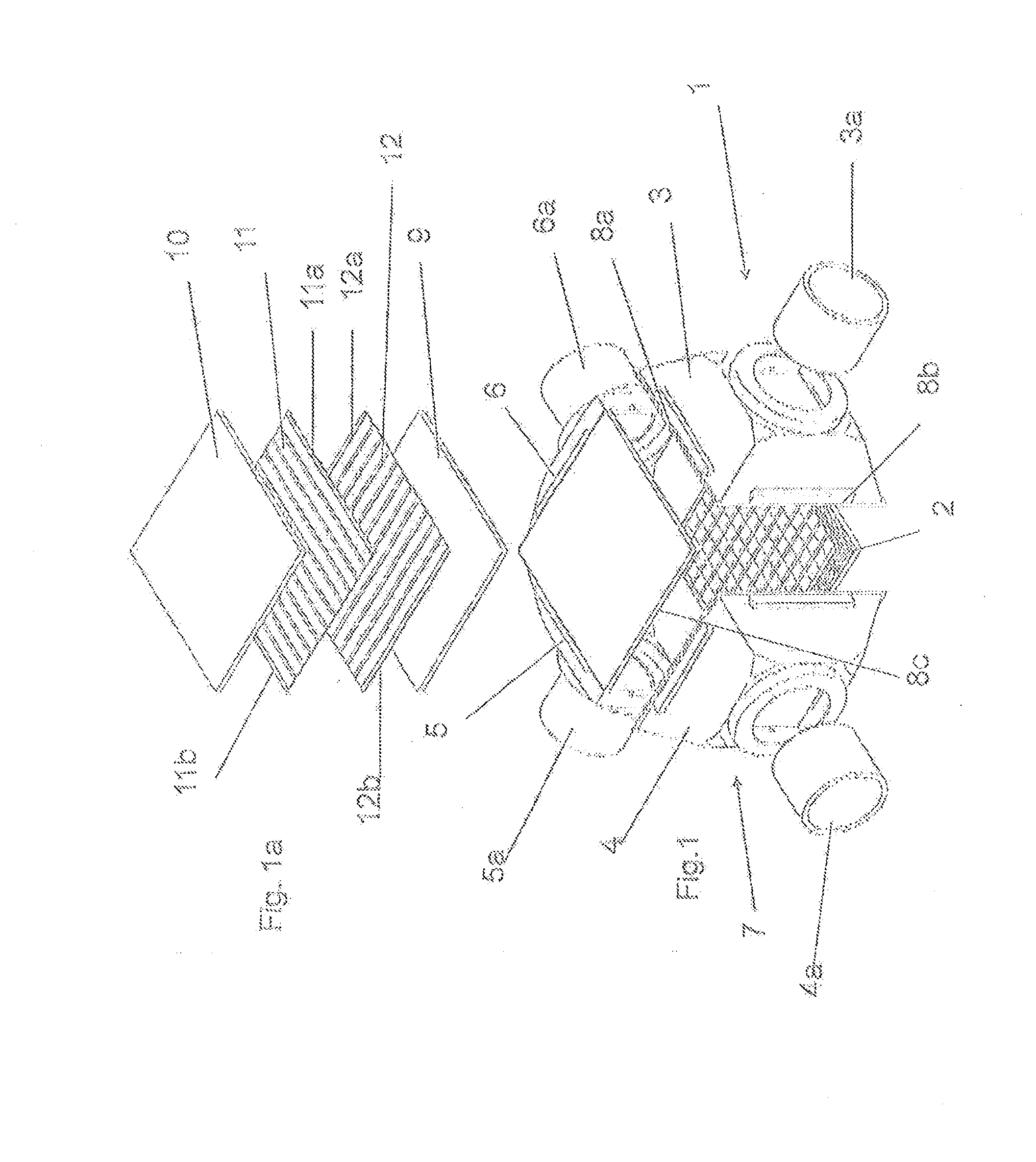

[0029]FIG. 1 shows a layer heat exchanger 1 in an exploded view. Such a layer heat exchanger 1 is known from the aforementioned state of the art with respect to its structure. A partially shown layer block 2, through which two media can flow in crossflow, is arranged in the interior of layer heat exchanger 1. Layer block 2 is housed in four box-like housing sections 3, 4, 5, 6, which in turn have connecting pieces 3a, 4a, 5a, 6a for supplying and removing the media flowing through layer block 2. The four box-like housing sections 3, 4, 5, 6 including the connecting pieces 3a, 4a, 5a, 6a are together also called a housing 7 below. Layer block 2 and housing 7 are connected together by twelve welding seams, of which welding seams 8a, 8b, 8c are designated by way of example.

[0030]In FIG. 1 a, layer block 2 according to FIG. 1 is shown schematically by a bottom cover plate 9 and a top cover plate 10 and by two layer plates 11, 12. Layer plates 11, 12, also called layer sheets 11, 12, are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com