Container superior in air-tightness and a method of keeping gas molecules or volatile components in the container

a technology of air tightness and container, applied in the field of containers, can solve the problems of low gas permeation properties of metal foil laminated films, inability to keep bottles air tight, and difficulty in ensuring the sealing effect, and achieve the effect of superior gas-barrier properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

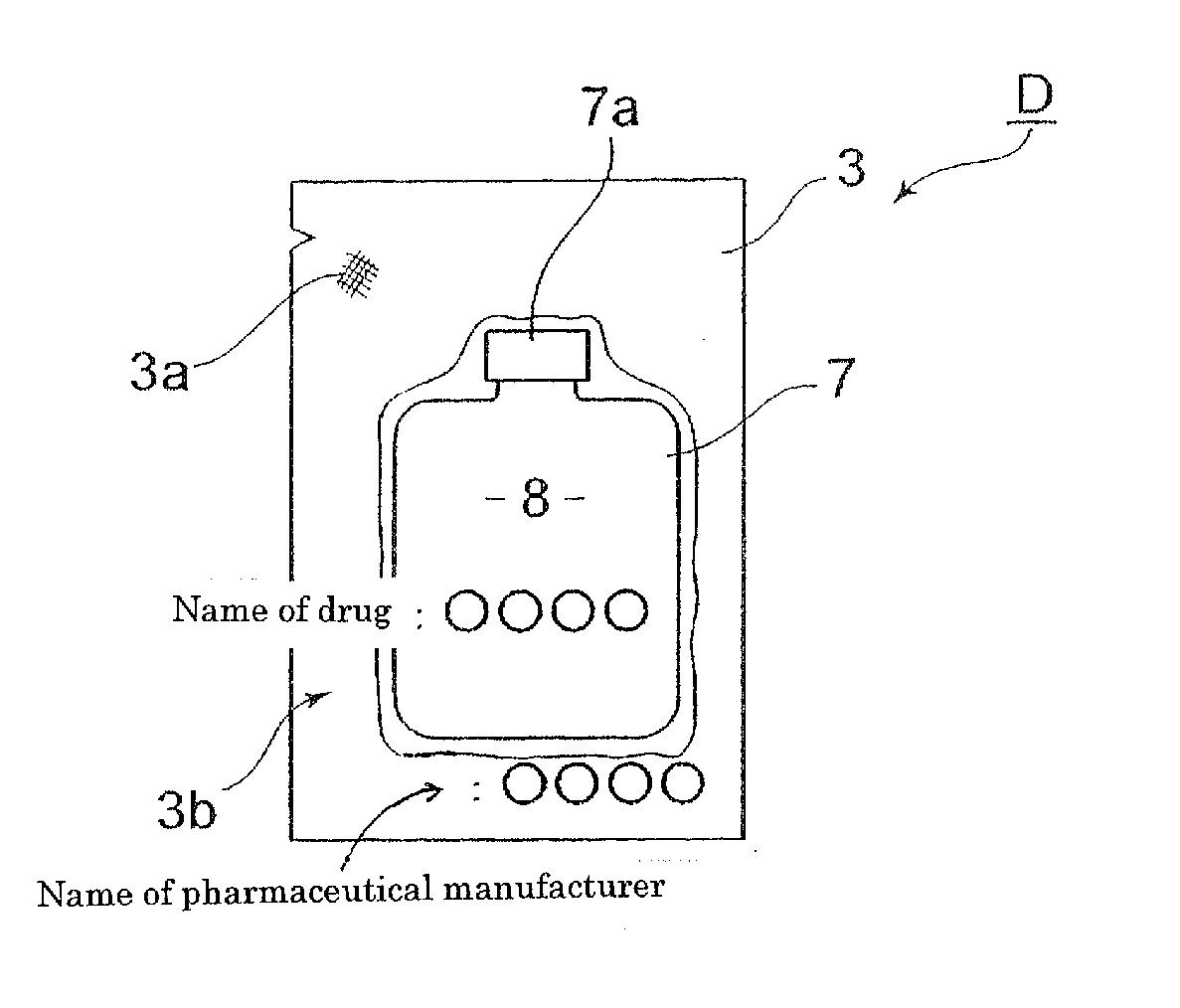

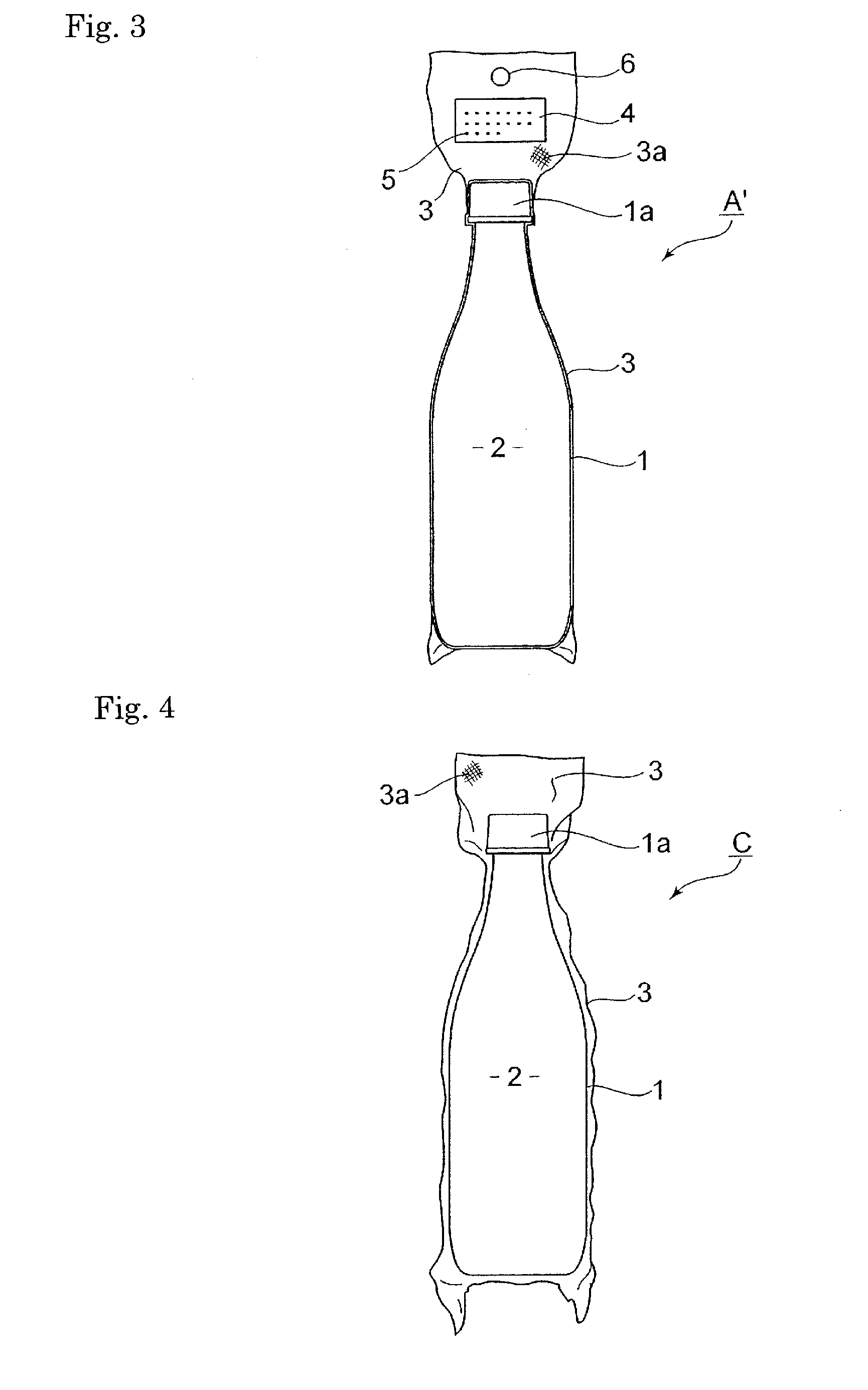

[0051]FIG. 1 shows an example of the present invention. Filled up to a mouth of a bottle 1(the container), capacity of 500 cc, made of polyethylene terephthalate was a hydrogen molecules dissolved water 2 dissolving hydrogen molecules at concentration of approximately 1000 ppb. The polyethylene terephthalate bottle 1 was packed with an aluminum foil laminated film 3 and vacuum packaged, so that the film 3 was tightly adhered to the bottle 1, thereby achieving a container A containing hydrogen water and superior in air-tightness. Reference numeral 1a designates a cap (made of polyethylene) for the polyethylene terephthalate bottle 1.

[0052]Ten containers A superior in air-tightness were manufactured by packing the polyethylene terephthalate bottle 1 filled with the hydrogen water with an aluminum foil laminated film 3, and vacuum packaging the same. And the package was opened one by one every few days to measure concentration of hydrogen in the hydrogen water. Table 1 shows the result...

example 2

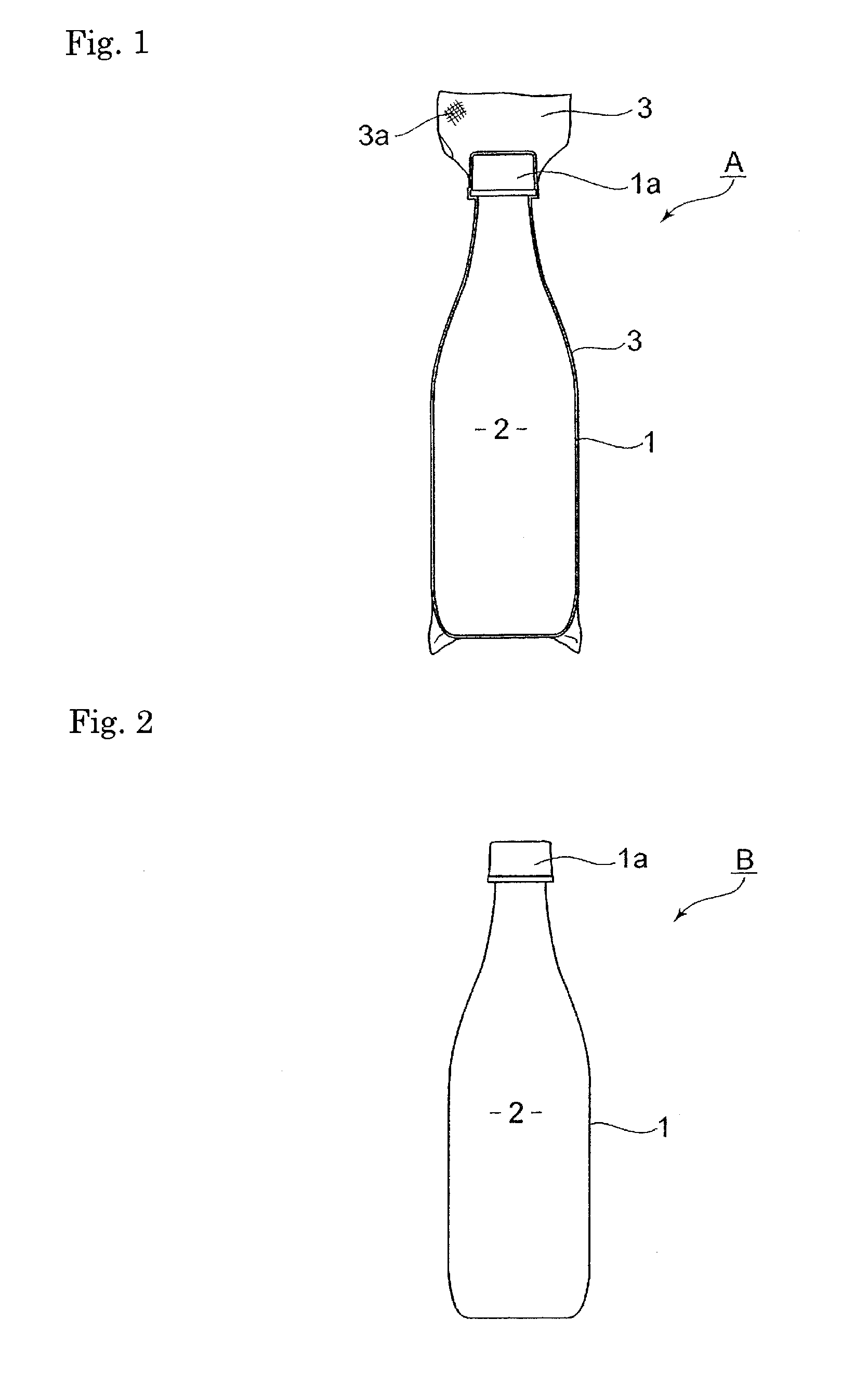

[0059]FIG. 3 shows a container A′ containing hydrogen water and superior in air-tightness which container is provided by that a bottle 1 made of polyethylene terephthalate was, similarly to FIG. 1, packed with an aluminum foil laminated film 3 and then vacuum packaged at vacuum of −760 mmHg. And a label 4 was put on at the upper part of the aluminum foil laminated film packaging 3 and there is written an indication 5 such as the name of contents of the polyethylene terephthalate bottle, the date of bottling, deadline for consumption, etc. Reference numeral 6 is a hole for suspending the whole package of bottle.

example 3

[0060]A bottle 1 made of polyethylene terephthalate provided in a similar manner to Example 1 was packed with a copper foil laminated film and vacuum-packaged to cause the film to adhere to the bottle 1, thereby obtaining a container containing hydrogen water and superior in air-tightness. Ten such containers were prepared and dissolved hydrogen was measured in a similar manner to Example 1. As shown in table 1, concentration of hydrogen molecules did not change even after 20 days passed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com