Methods for extracting keratin proteins

a technology of keratin protein and extraction method, which is applied in the direction of peptide/protein ingredients, peptide sources, peptides, etc., to achieve the effect of minimizing the degradation of said keratin protein

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

6.1 Example 1

Keratose Extraction Methods (Oxidative Extraction)

[0058]Untreated Chinese hair was used in the extraction method. The hair was end-cut to lengths of ¼, ½, ¾ and 1 inch segments and cleaned by washing in a warm water solution.

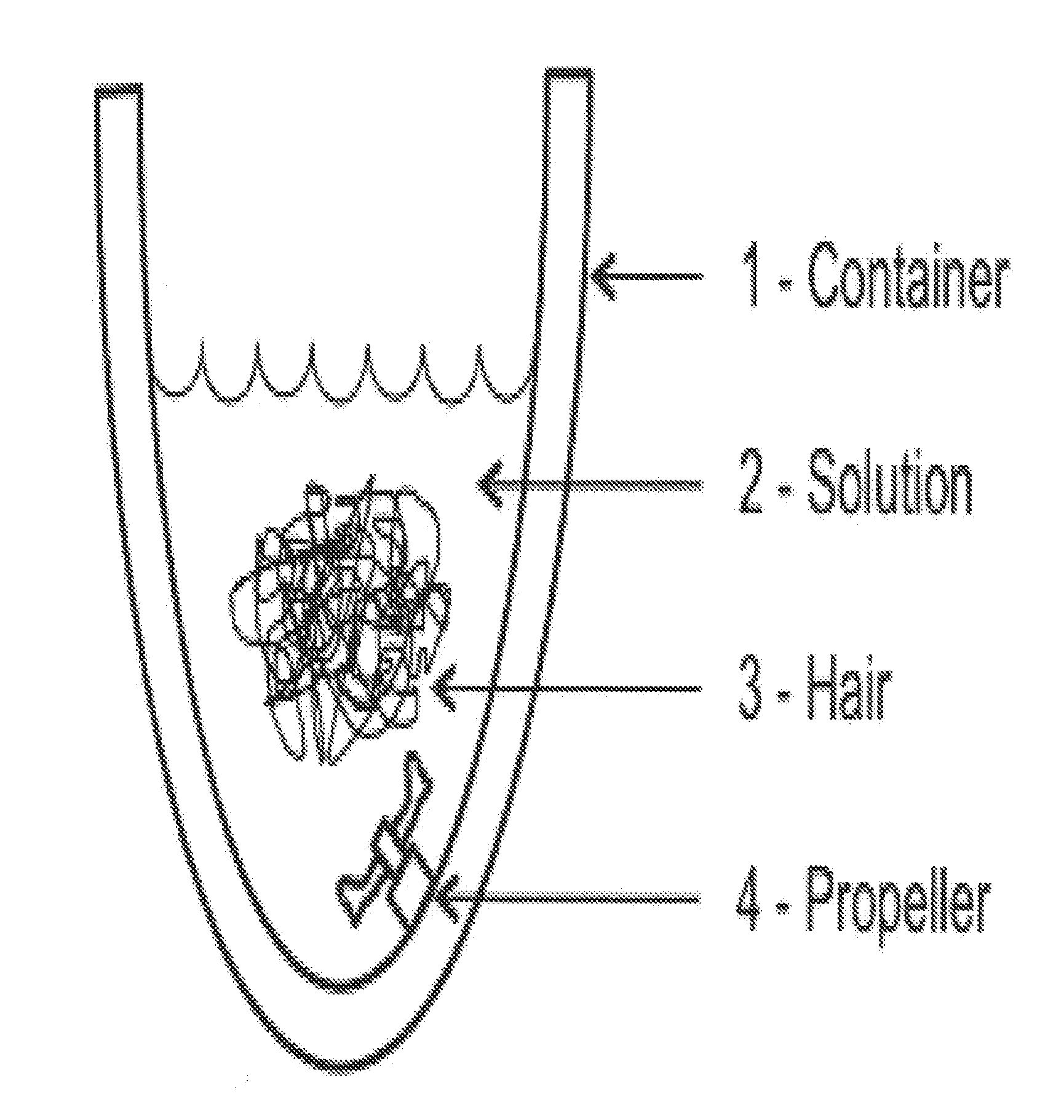

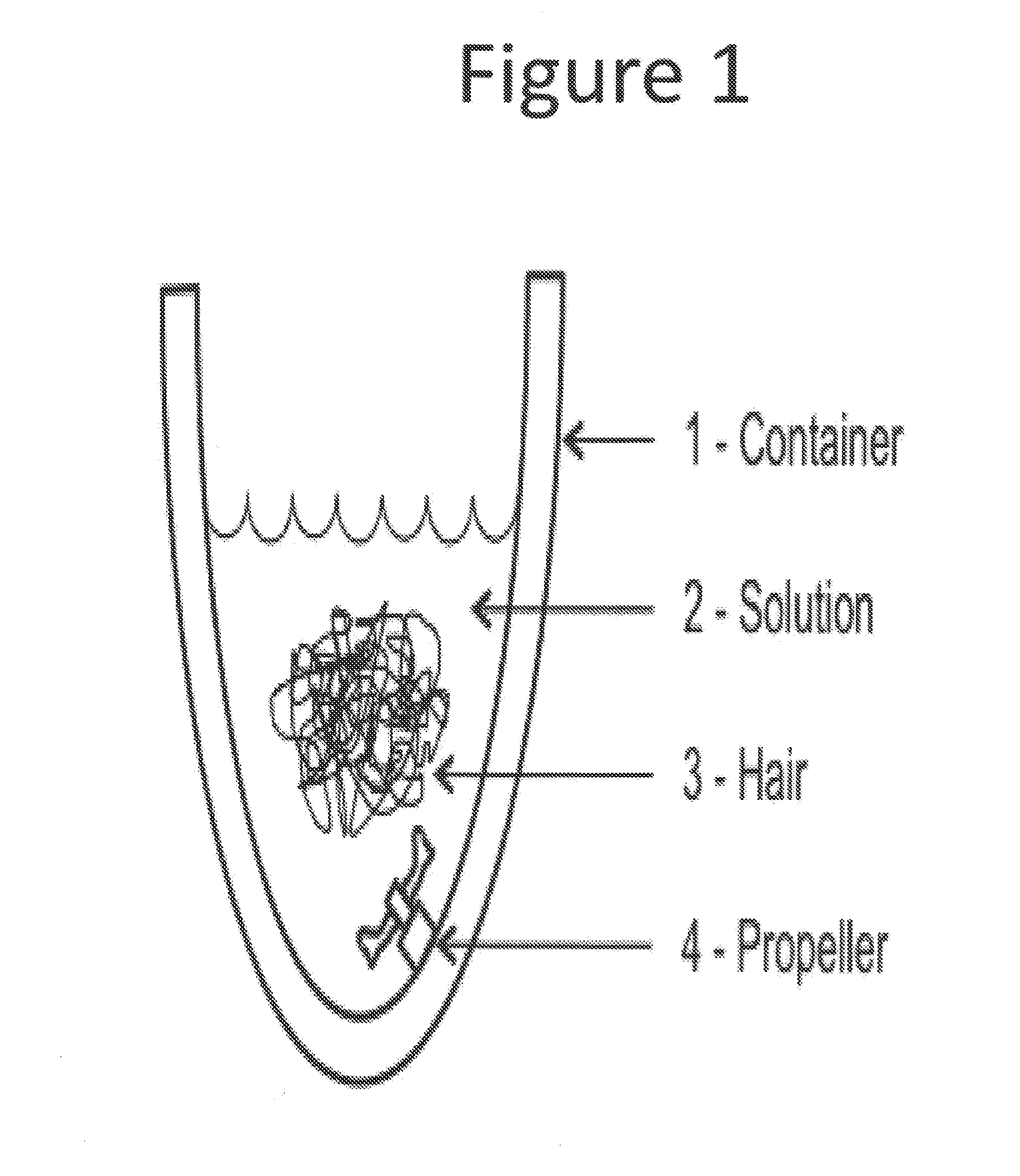

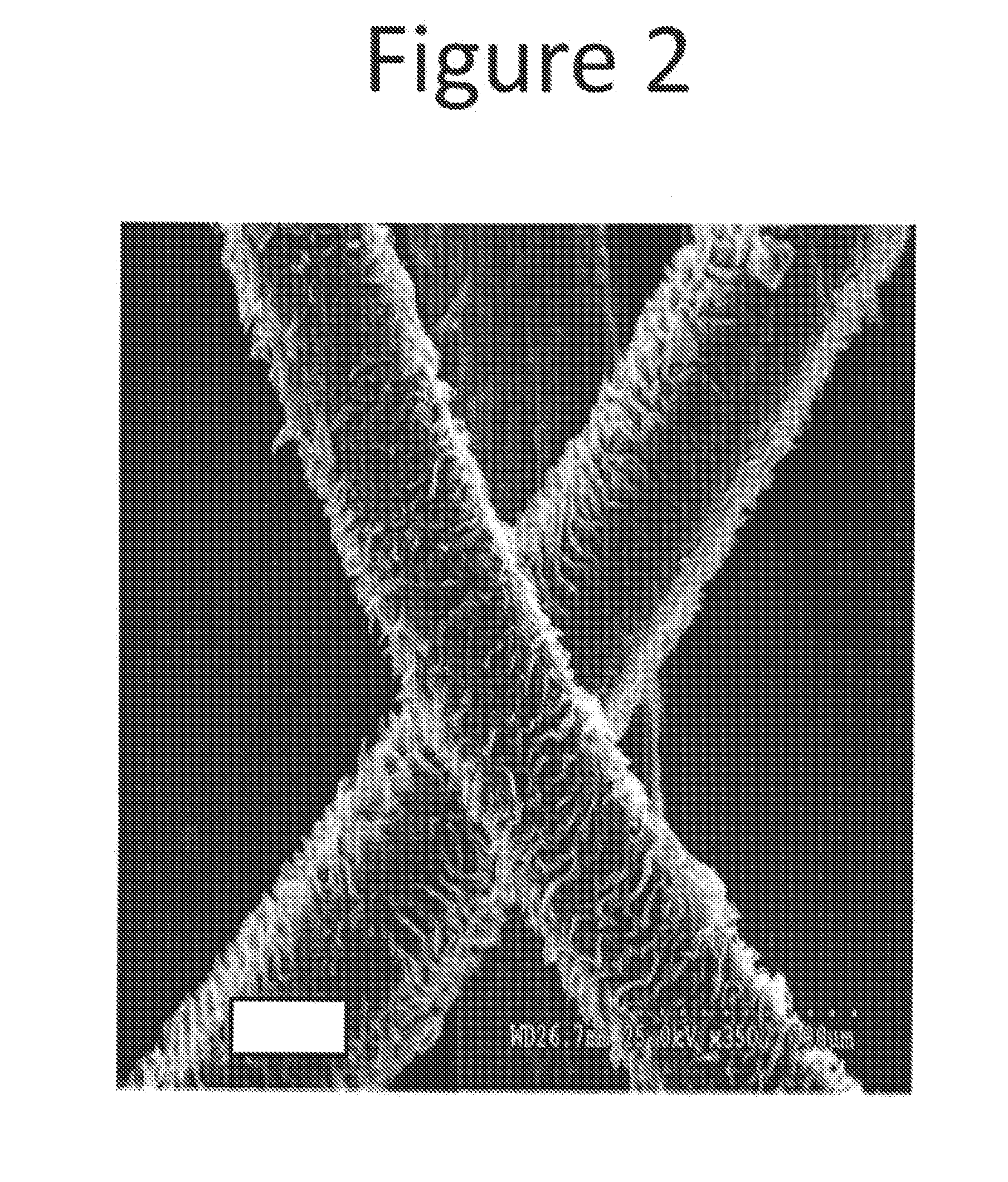

[0059]Step 1: The hair was added to a mixing tank. The tank was a 316L stainless steel vessel that contained a propeller for mechanical agitation (see FIG. 1). The oxidant was added to the vessel. The oxidant used was a 2% solution of paracetic acid (PAA) at a 25:1 weight-to-weight ratio. The mixture was mechanically mixed for a period of 12 hours at 37° C. The mechanical mixing resulted in complete oxidation of the hair shafts (see FIG. 2).

[0060]Step 2: The residual solution containing the oxidant was drained, neutralized and discarded.

[0061]Step 3: The oxidized hair was collected and rinsed with water until PAA test strips revealed no residual oxidant in the solution.

[0062]Step 4: A base was then added to the drained hair in a ratio of 25:1. In th...

example 2

6.2 Example 2

Kerateine Extraction Methods (Reductive Extraction)

[0073]Kerateine Extraction Methods (Reductive Extraction).

[0074]Untreated Chinese hair was end-cut to lengths of ¼, ½, ¾ and 1 inch segments and washed in a warm water solution.

[0075]Step 1: The hair was added to a 316L stainless steel vessel that contained a propeller for mechanical agitation (see FIG. 1). The reductant was added to the vessel. The reductant was a 0.5M solution of a thioglycolic acid (TGA) at a ratio of 25:1. The mixture was mechanically mixed for a period of 15 hours at 37° C. The mechanical mixing can be beneficial to improve the extent to which reduction occurs in the hair shafts.

[0076]Step 2: The solution containing reductant and extracted keratin proteins was collected and stored in a separate container at 4° C. The remaining hair was retained by sieving through a steel mesh with a pore size of 400 microns. The mechanical agitation applied during the straining process helps to collect as much solu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pressure | aaaaa | aaaaa |

| Pressure | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com