Multielectrode array and method of fabrication

a technology of multi-electrode arrays and fabrication methods, applied in the field of multi-electrode arrays, can solve the problems of limited bonding technique, low adhesion strength, and short lifespan, and achieve the effects of enhancing neural growth or peripheral nerves, reducing the immune response, and reducing the risk of fractur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0059]Generally

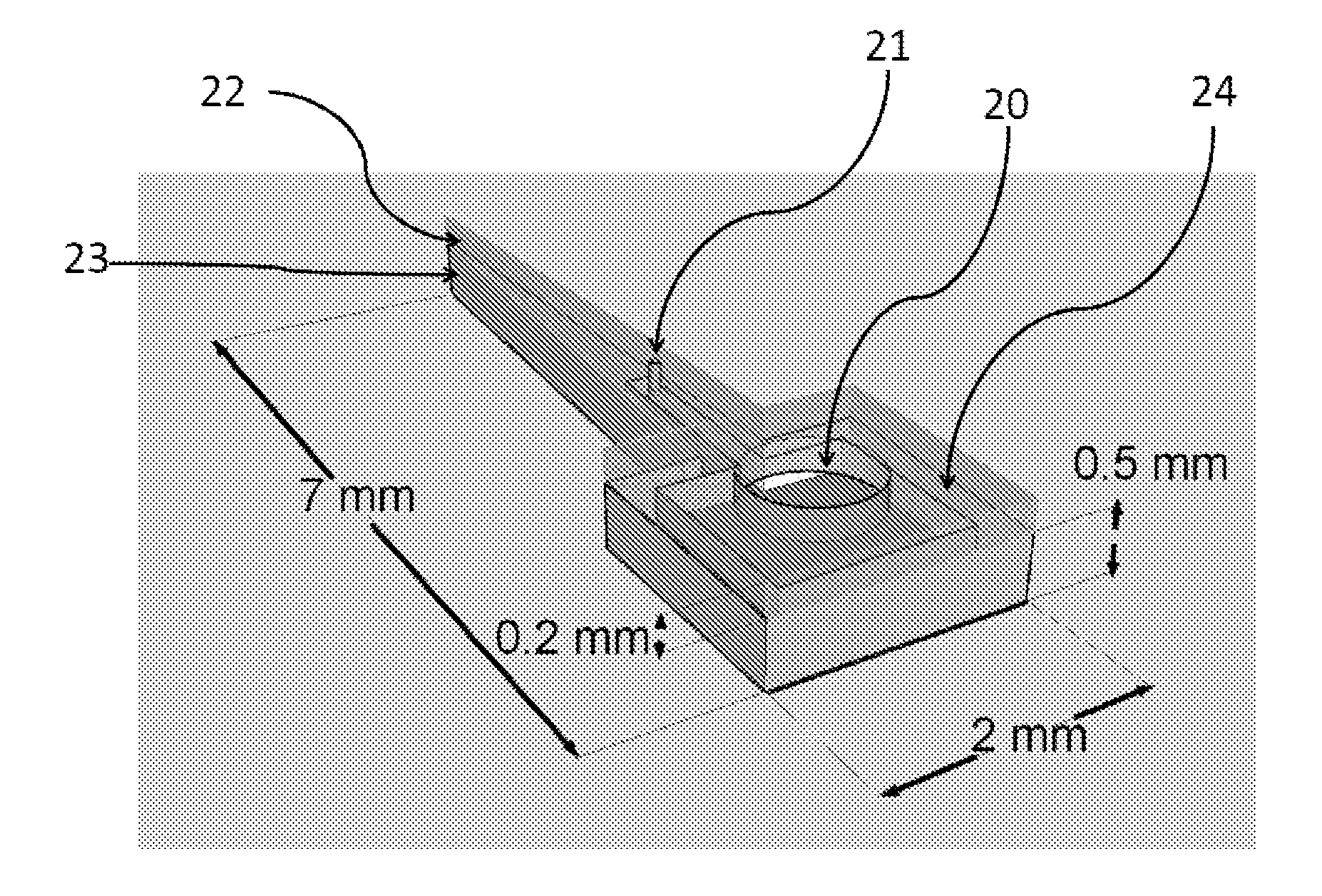

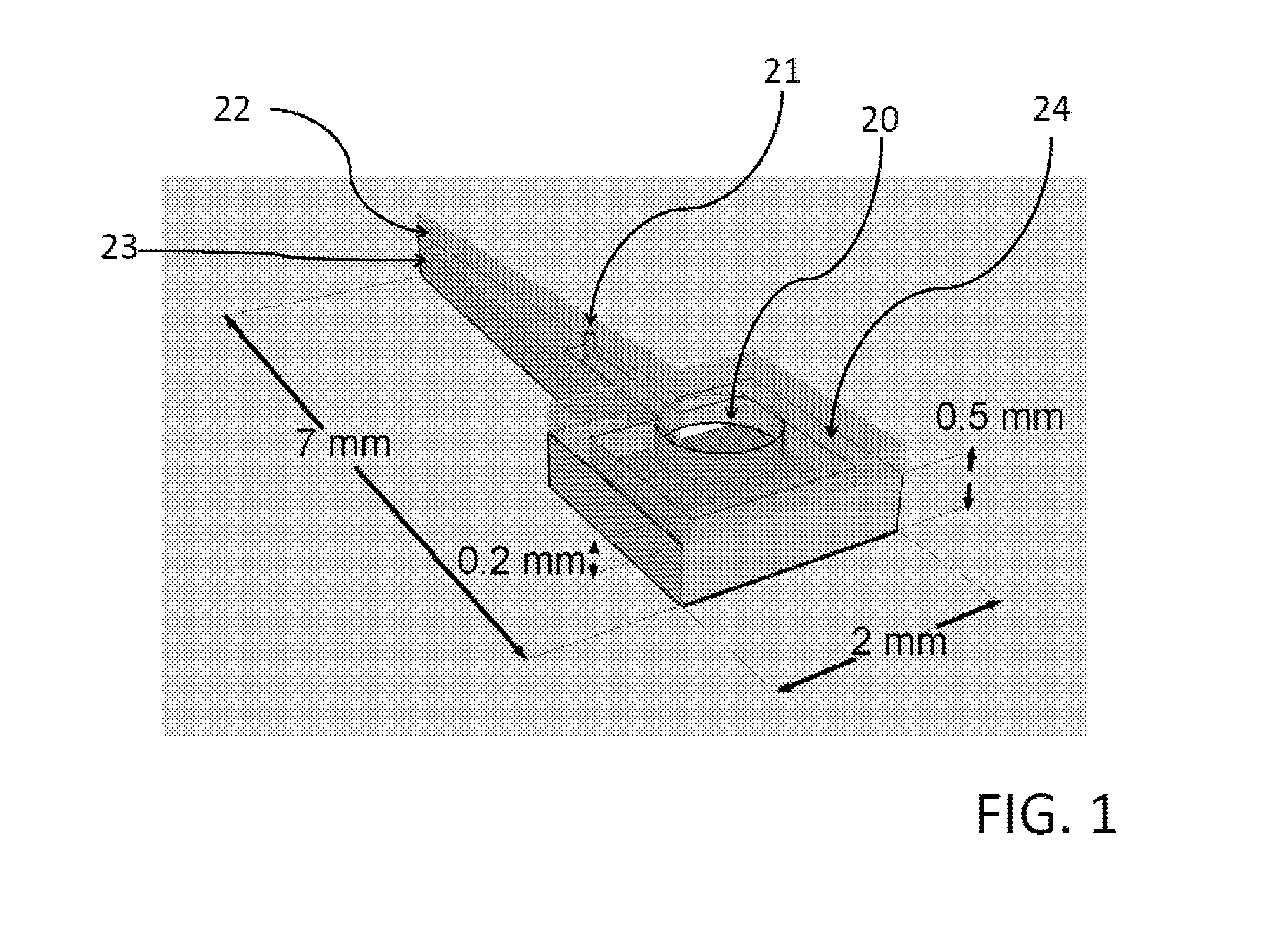

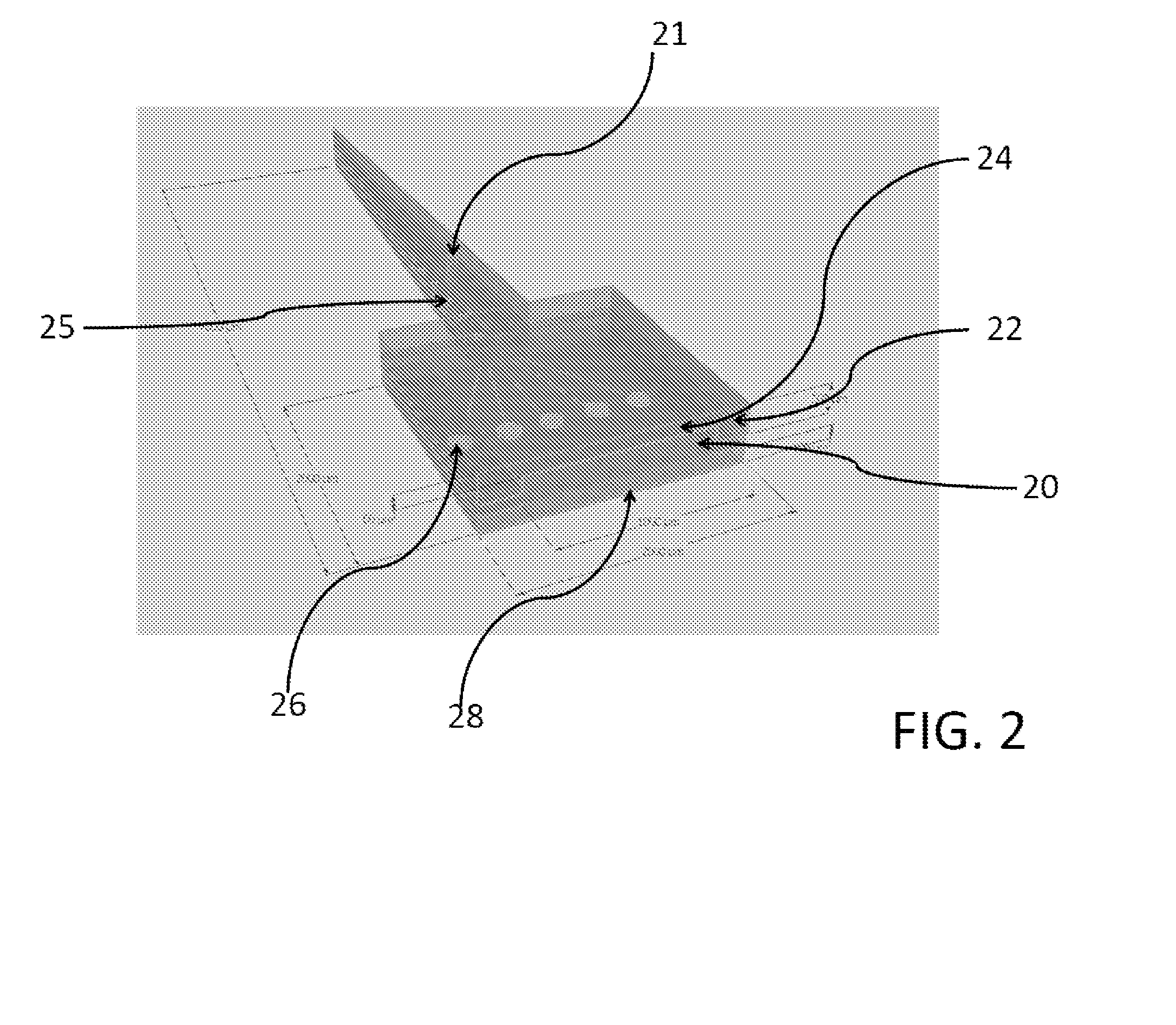

[0060]A silicon based microelectrode with an embedded fluidic channel is developed to deliver growth factors and drugs that would mitigate the cellular responses that have limited the chronic implementation of current multielectrode arrays. Two types of silicon based microelectrodes were developed, one with the fluidic channel etched into the silicon, and SU-8 was used to make the roof. The second consist of a silicon electrode with a SU-8 fluidic channel.

[0061]A third microelectrode that is made completely out of SU-8 (Shank, and fluidic channel) was constructed. In addition to delivering drugs and growth factors, a flexible SU-8 based neural probe with fluidic and electrical capabilities was developed to further extend the longevity of neural electrodes by reducing the tissue / electrode mechanical mismatch of traditional silicon based neural electrodes. In addition to extending the life of probe, the SU-8 material is a biocompatablie insulator with the potential for ...

example 2

[0064]Fabrication

[0065]Three preferred embodiments of the device are presented. In the first embodiment, a silicon microelectrode consist of at least one electrode site on one surface, on the opposite surface, a silicon channel is etched using microelectromechanical system technology, and the etched channel is sealed to form the fluidic channel in the microelectrode. In the second embodiment, a silicon microelectrode consist of at least one electrode site on one surface, on the opposite side, consist of fluidic channel that was photolithogoraphically fabricated. In third embodiment, the microelectrode consist entirely out of SU-8 and consist of a Fluidic channel and at least one electrode site. In these embodiments the electrode materials can easily change by those skilled in the art. The dimensions and manufacturing specification specified in the present invention are for illustration of the preferred embodiment, and can easily be changed by those skilled in the art, and with new m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelengths | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com