Demister Apparatus and Method

a technology of demister apparatus and cylinder, which is applied in the direction of filtration separation, auxillary pretreatment, separation process, etc., can solve the problems of health hazards, maintenance burden, air pollution problems, etc., and achieve the effect of reducing the total power consumption of the fan motor, reducing the power consumption required, and reducing the rate of air flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027]In the following detailed description, certain specific terminology will be employed for the sake of clarity and a particular embodiment described in accordance with the requirements of 35 USC 112, but it is to be understood that the same is not intended to be limiting and should not be so construed inasmuch as the invention is capable of taking many forms and variations within the scope of the appended claims.

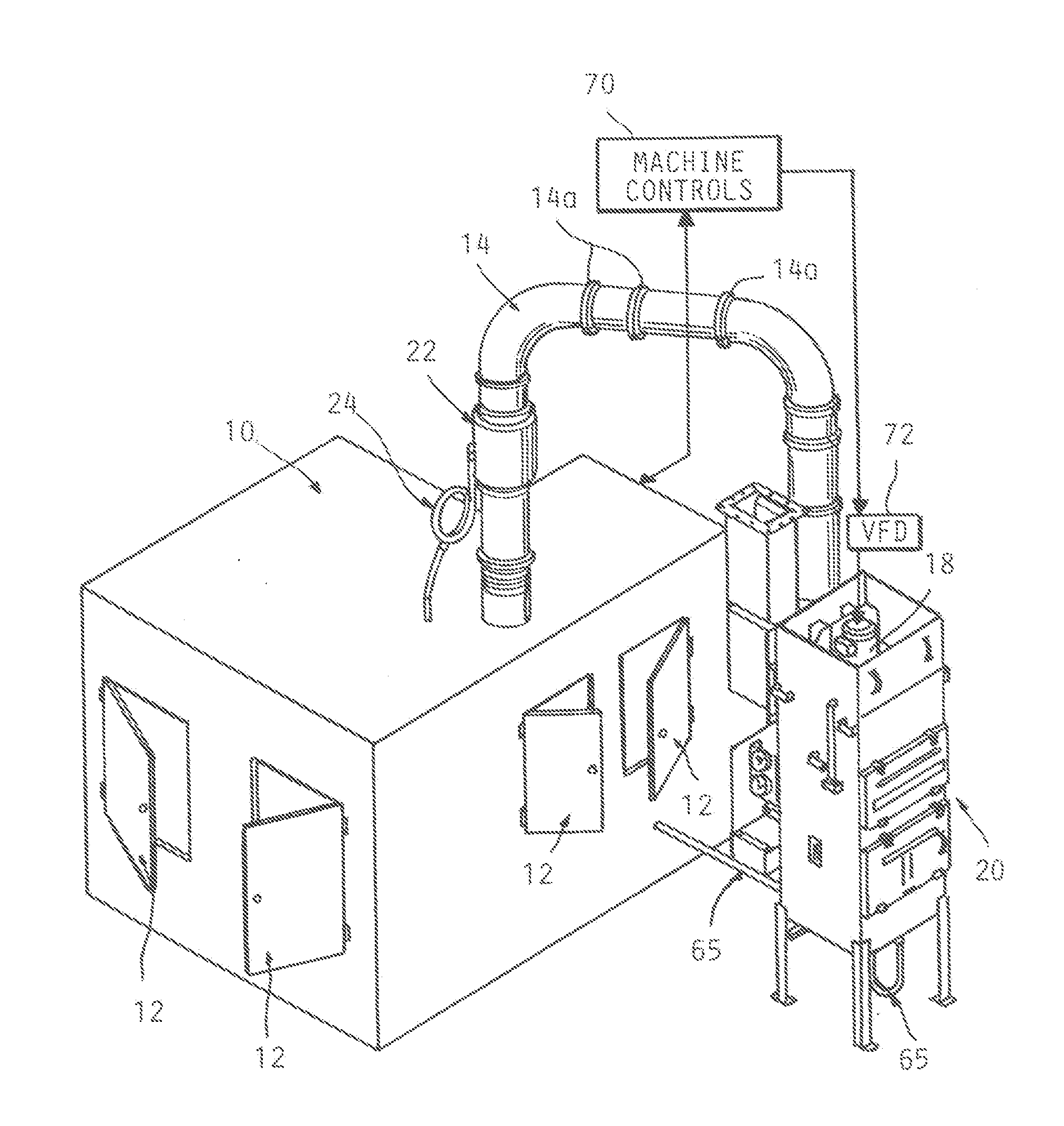

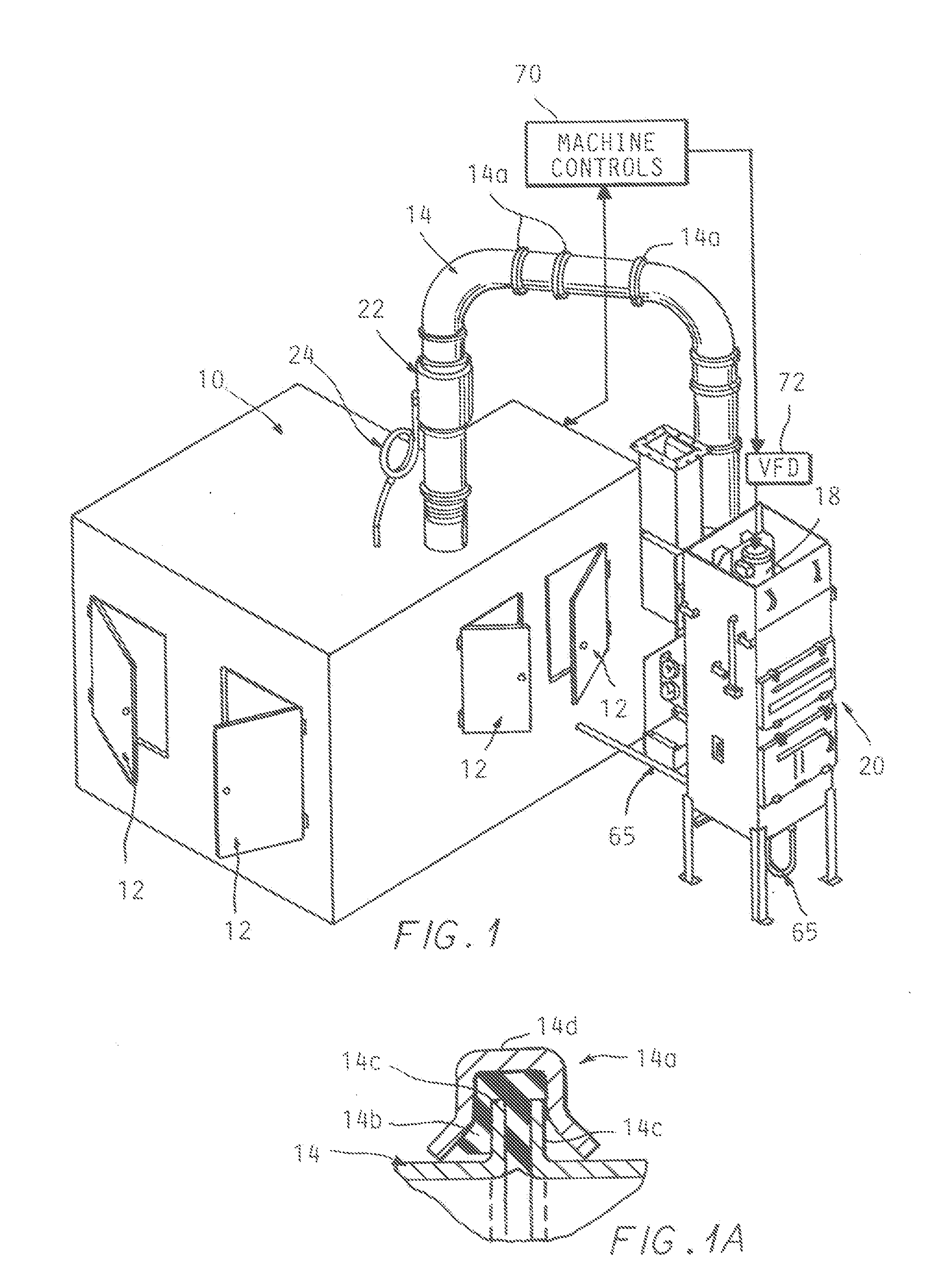

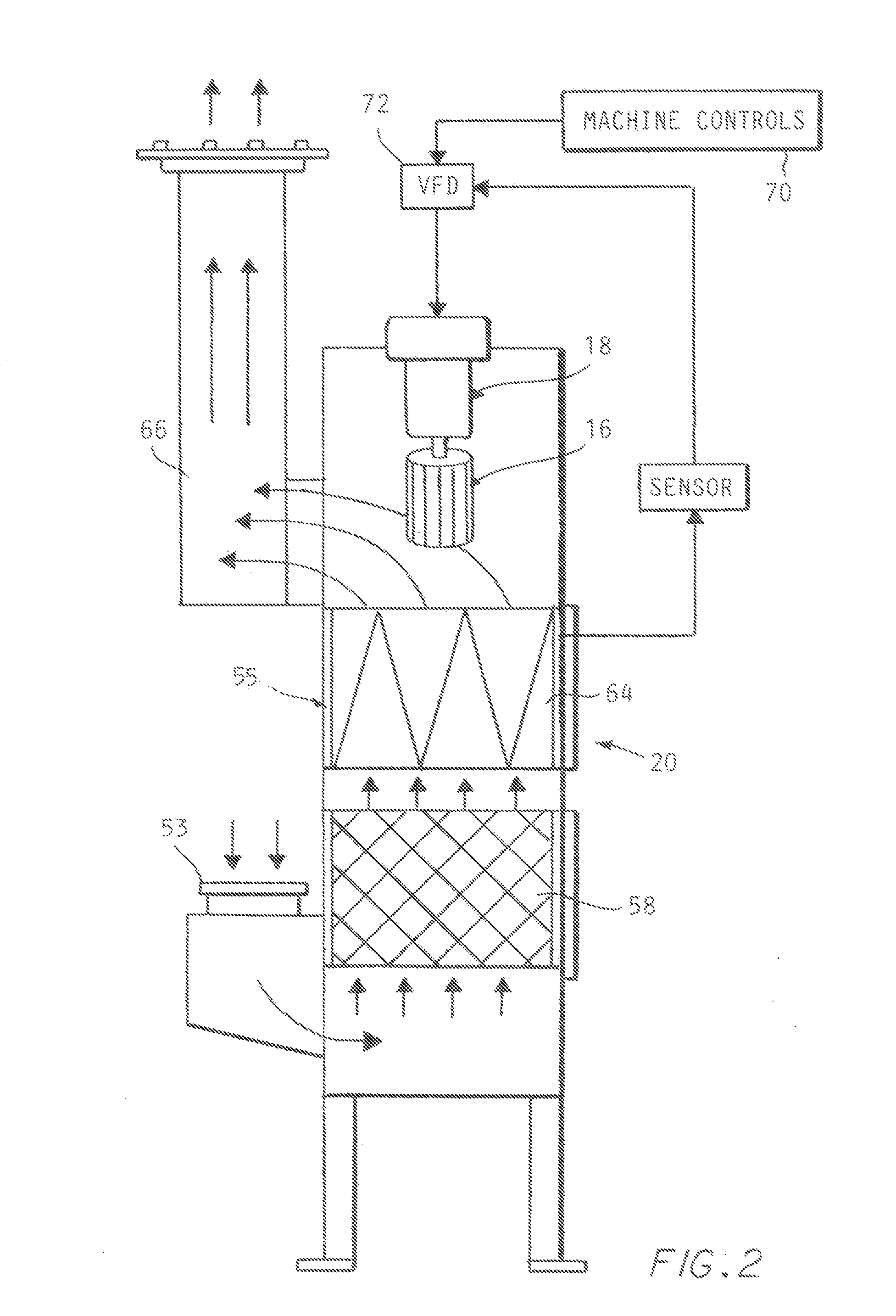

[0028]Referring to FIG. 1, a machining center booth 10 is shown which encloses a conventional automated CNC machining station (not shown) in which parts are machined with the use of metal cutting tools in the well known manner.

[0029]The parts are typically unloaded after one or more access door panels 12 are opened, as indicated in FIG. 1 by load / unload robots or other part handling devices (not shown), which then load parts to be machined into the machines, with the access door panels then closed.

[0030]As noted, such machining operations use metal cutting tools which in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pressure | aaaaa | aaaaa |

| Power | aaaaa | aaaaa |

| Flow rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com