Display Device and Manufacturing Method Thereof

a technology of light-emitting elements and display devices, which is applied in the direction of sustainable manufacturing/processing, instruments, and final product manufacturing, etc., can solve the problem of glass element substrates being broken due to sudden changes in temperature, and achieve the effect of improving scattering properties and preventing diffraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment mode 1

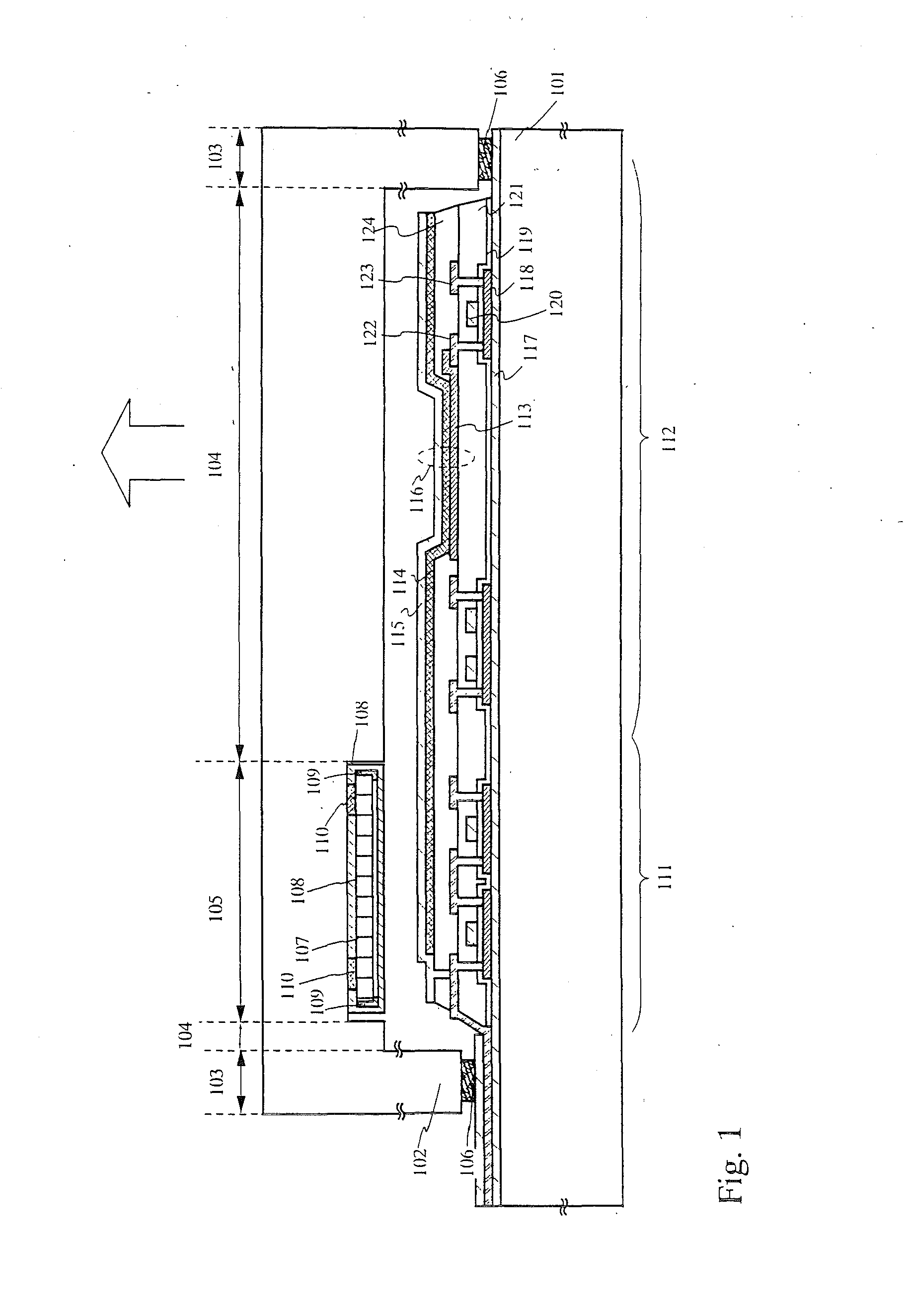

[0082]An embodiment mode of the present invention will be described using FIG. 1. FIG. 1 is a cross sectional view of an active matrix display device using an organic light emitting element.

[0083]A driver circuit portion 111 and a pixel portion 112 which are composed of TFTs are formed on a first substrate (element substrate) 101.

[0084]Substrates made of glass such as barium borosilicate glass, aluminoborosilicate glass, or quartz glass are used as the first substrate and the second substrate (sealing substrate) 102.

[0085]The surface of the second substrate is processed by an abrasive machining method and selectively shaved. By this processing, the surface of the second substrate has a first region 103, a second region 104, and a third region 105. The first region is a surface to which a layer having adhesion is adhered. When viewed from a rear surface of the second substrate, the first region is protruded in a convex shape relative to the second region and the third region.

[0086]An...

embodiment mode 2

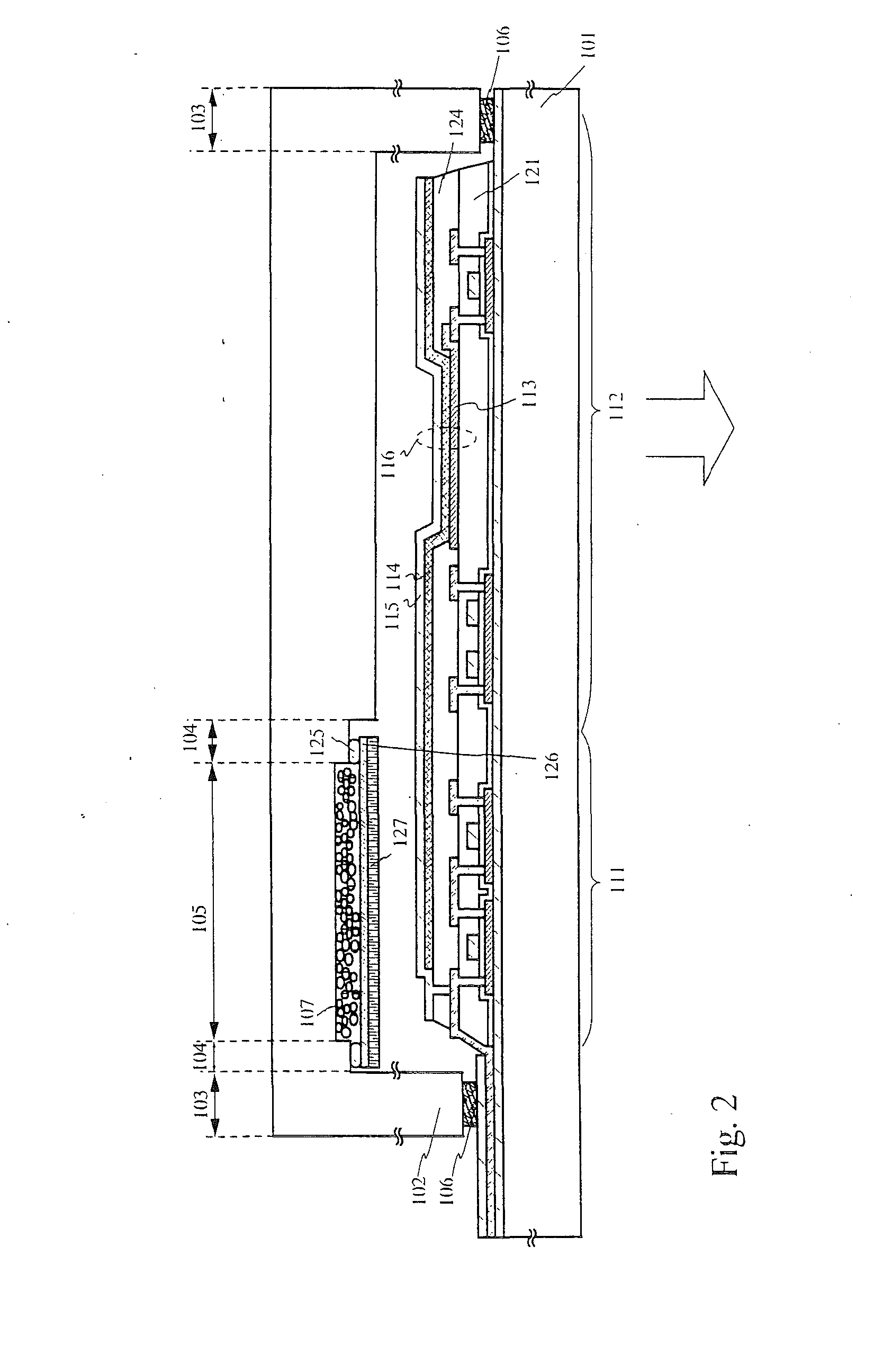

[0112]In this embodiment mode, an example where a dry agent and a permeable film are provided over a driver circuit portion is indicated. In this embodiment mode, points which are different from Embodiment Mode 1 will be described in detail. This embodiment mode will be described using a cross sectional view of FIG. 2. FIG. 2 is a cross sectional view of an active matrix display device using an active matrix organic light emitting element. Shown in the drawing is a driver-circuit-integrated structure in which a pixel portion 112 and a driver circuit portion 111 are formed on the same substrate.

[0113]Substrates made of glass can be used as a first substrate 101 and a second substrate 102.

[0114]In this embodiment mode, a granular material is used for a dry agent 107. When the dry agent is granular, a surface area thereof is increased and thus it is easier to absorb moisture. It is desirable that a particle size of the dry agent is set to be 10 μm to 80 μm. In this embodiment mode, the...

embodiment mode 3

[0122]This embodiment mode will be described using FIG. 3. As shown in FIG. 3, in a display device in which an organic light emitting element 116 is provided, minute unevennesses are formed on the surface of a substrate onto which light emitted from the organic light emitting element is outputted. Hereinafter, this embodiment mode will be described in detail.

[0123]In this embodiment mode, the organic light emitting element 116 has a structure in which a cathode 113, an organic compound layer 114, and an anode 115 are laminated in order, and light from the organic light emitting element 116 is emitted to the side indicated by an arrow in the drawing. In other words, a user views an image from a second substrate 102 side. At this time, outside light is reflected at the interface between the second substrate 102 and a sealed space and in an interface between the second substrate and air. Thus, unwanted reflection of an ambient background view is caused. In order to prevent such a pheno...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com