Method for producing high purity lignin

a lignin and high purity technology, applied in the field of high purity lignin production, can solve the problems of increasing the investment cost of recovery systems, the commercial viability of the process is lower, and the cost of fresh chemicals is a large part of the operational cost, so as to reduce the carbohydrate content and reduce the loss of lignin produced

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

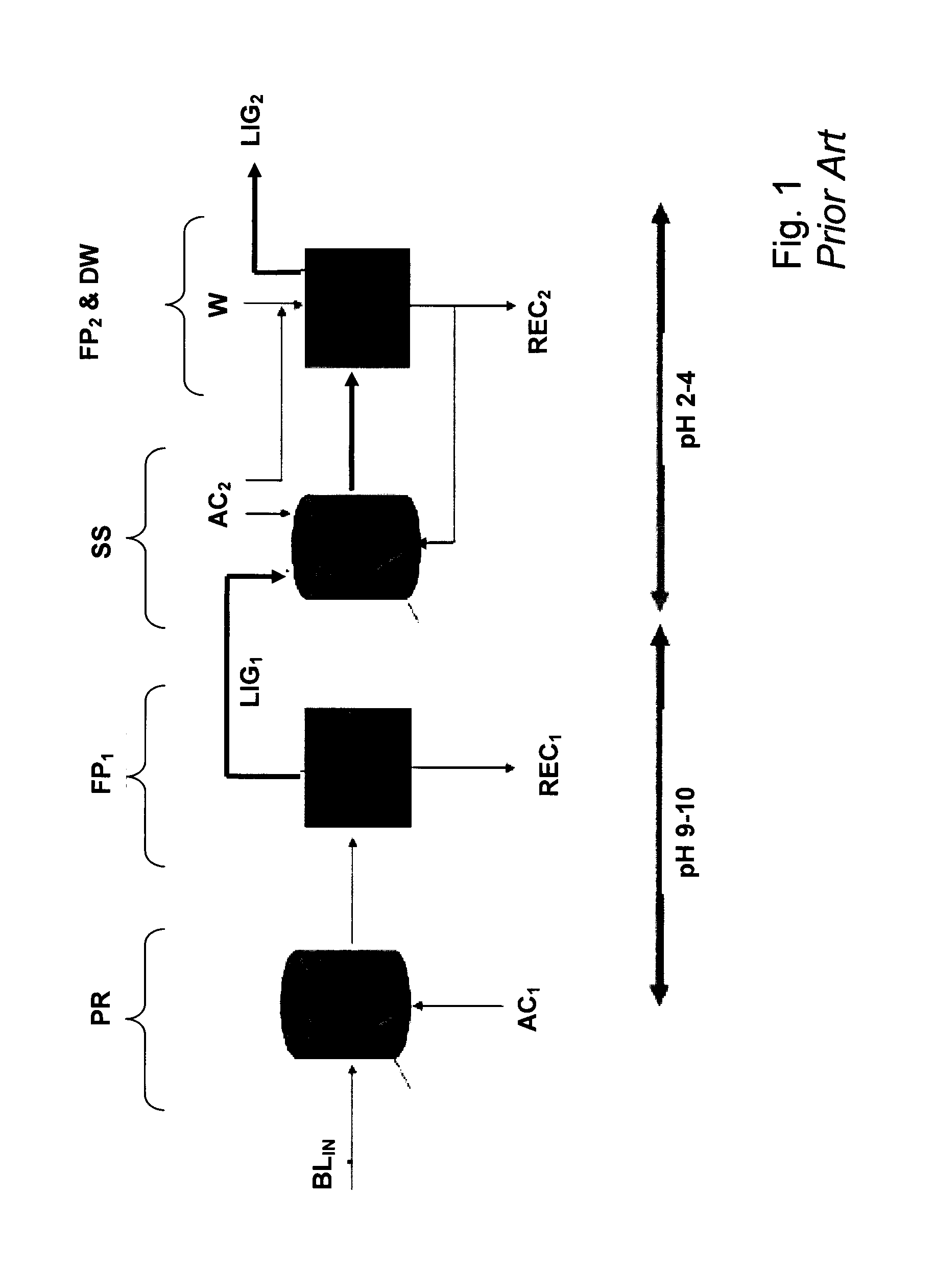

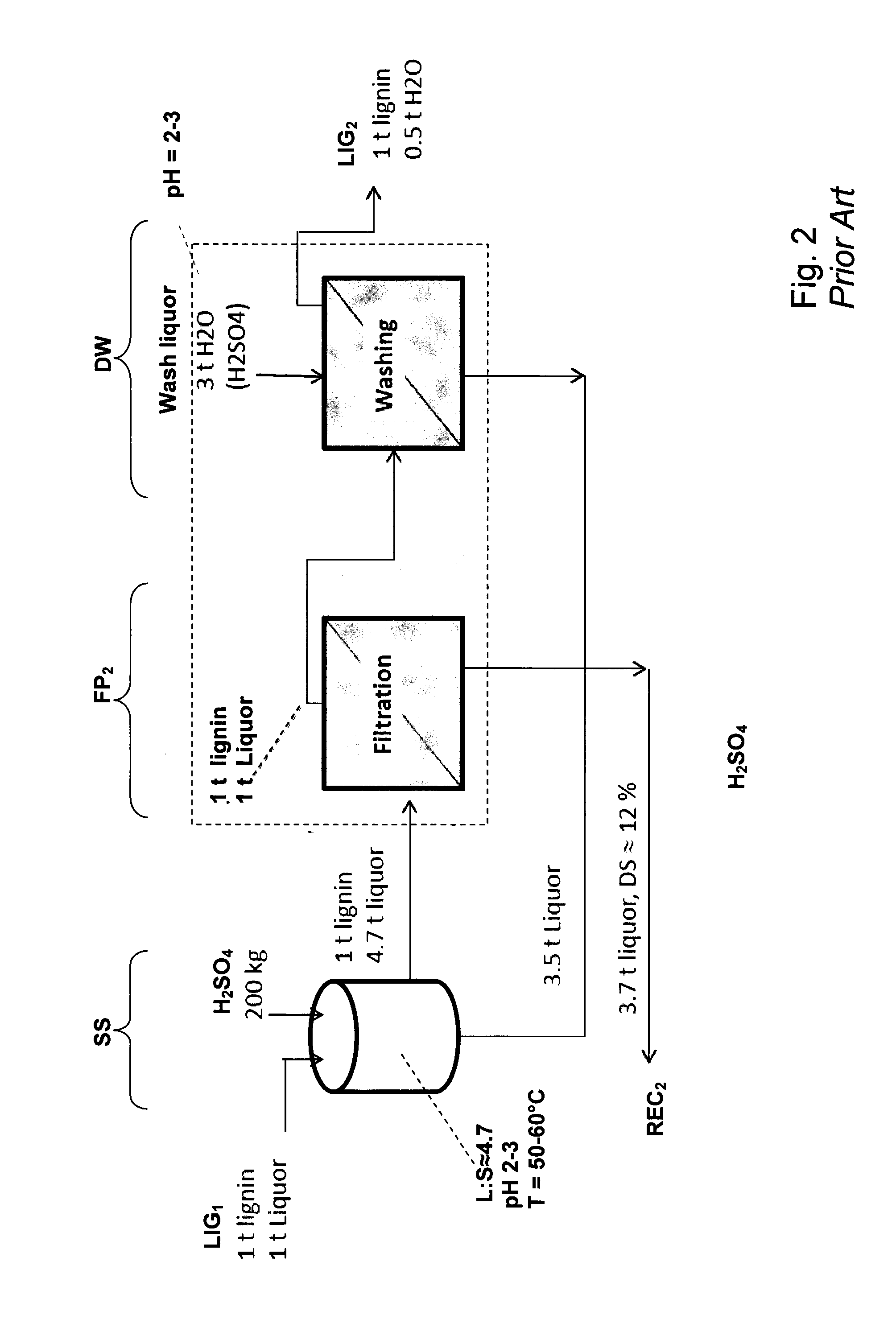

[0048]As a starting point for the invention was the LignoBoost™ process used, which is shown in principle in FIGS. 1 and 2.

[0049]In FIG. 1 is the process according to WO 2006 / 031175 shown. The separation of lignin from original black liquor BLIN comprising the following stages in sequence:[0050]Precipitation of lignin by a first acidification stage PR of the original black liquor BLIN by adding a first acid or mixture of acids AC1, in any suitable precipitation reactor, followed by[0051]dewatering while forming a first filter cake LIG1 with high content of lignin, said dewatering made in any suitable filter press FP1, which may drain a first filtrate REC1 from the lignin suspension. In order to reduce the amount of liquid in the filter cake LIG1 gas may be blown trough the lignin cake in order to displace any residual black liquor (not shown), and subsequently[0052]suspending the first lignin filter cake LIG1 in a second acidification stage SS using a second acid or mixture of acids...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com