Fan-metal fiber gas burner

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

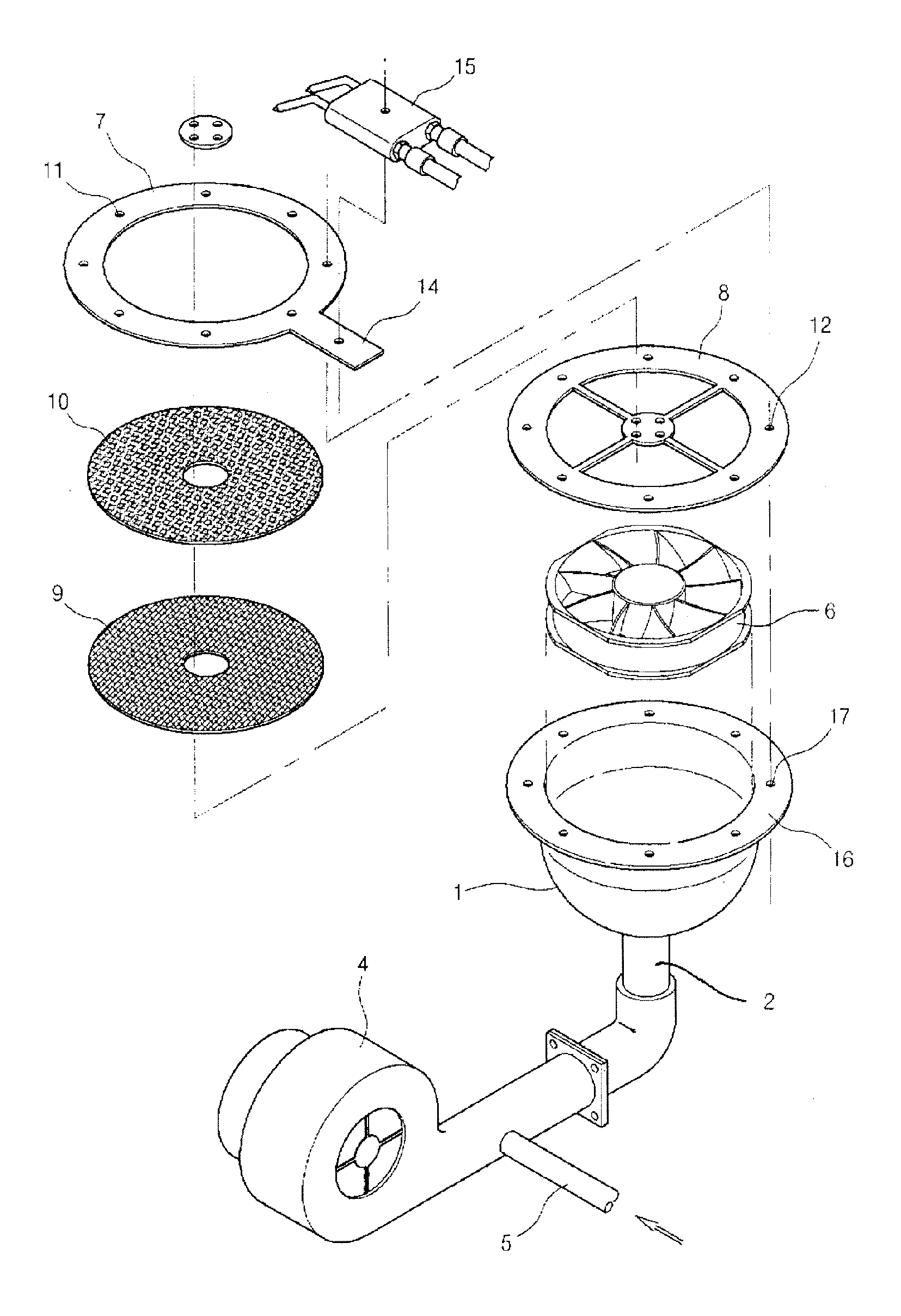

[0028]As shown in FIG. 1, a fan-metal fiber gas burner according to the present invention includes a burner head 1, a supply pipe 2 connected to the central portion of a bottom of the burner head 1 to communicate with an inside of the burner head 1, a pad 3 mounted on a combustion part of the burner head 1, a blower 4 installed to a rear end of the supply pipe 2, a gas supply apparatus 5 installed to the supply pipe 2 at the front of the blower 4 and an idle-type dispersing blade 6 installed to an inside of the burner head 1.

[0029]The pad 3 is formed by sequentially stacking a metal mesh 9 and a metal fiber 10 and fixed between an upper fixing rim and a lower fixing rim 8. The pad 3 utilizes a tissue property of the metal fiber 10, so that the gas is uniformly spread out through the entire surface of the pad 3 and burned to quietly explode flame.

[0030]The blower 4, which is an air volume variable blower capable of controlling an air flow rate, supplies an air together with gas throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com