Voltage sensor for high and medium voltage use and a method of making the same

a high and medium voltage, voltage sensor technology, applied in the direction of instruments, base element modifications, measurement instrument housings, etc., can solve the problem of high cost of solution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

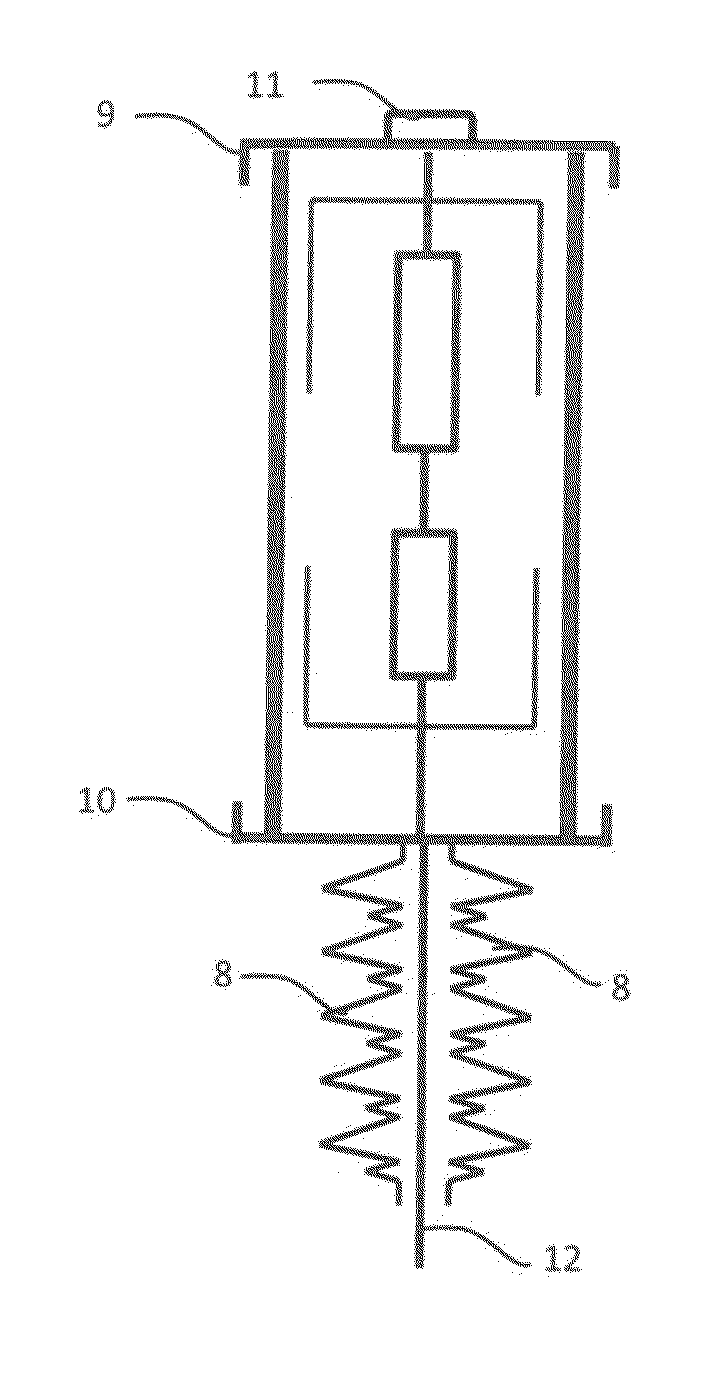

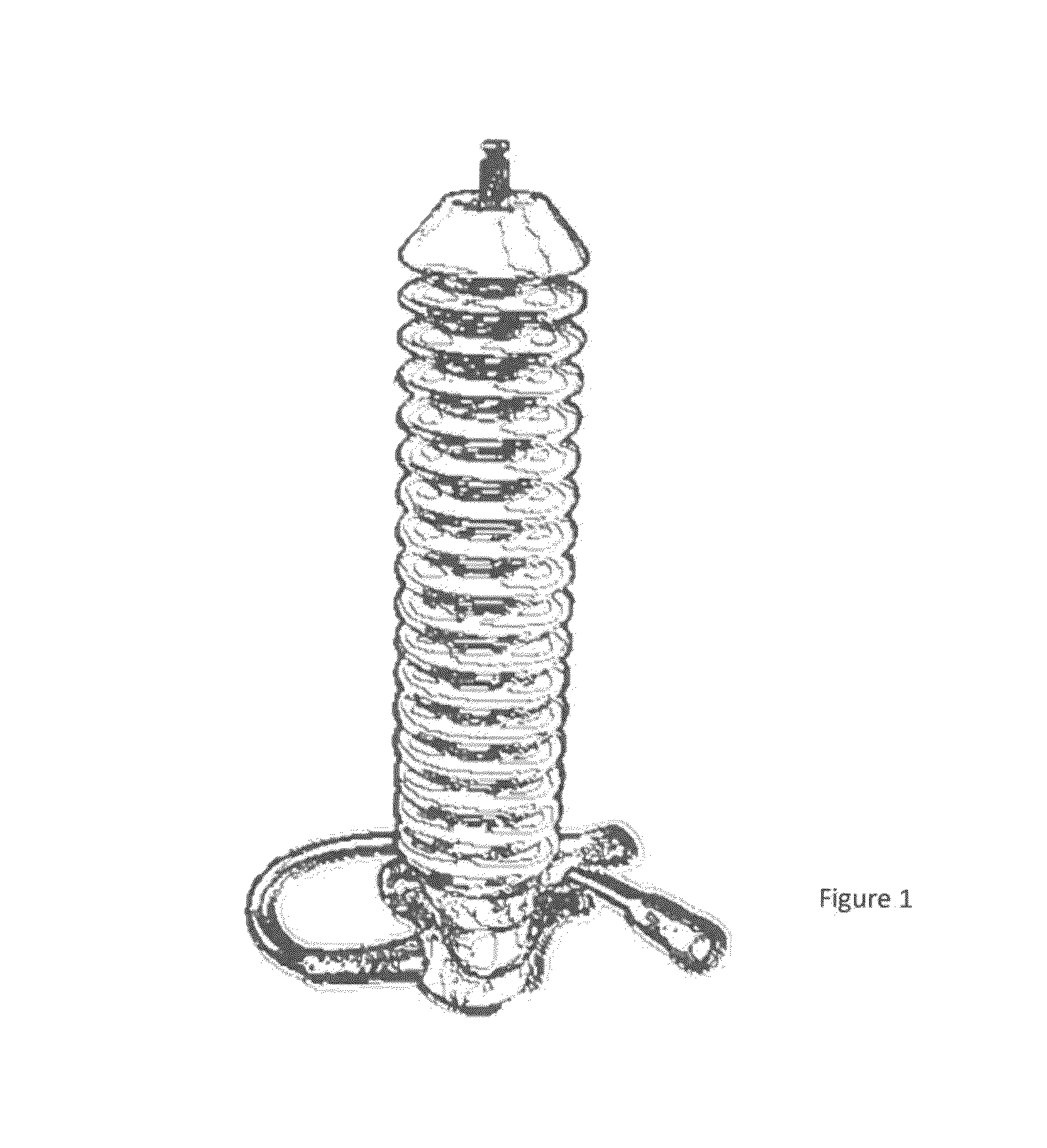

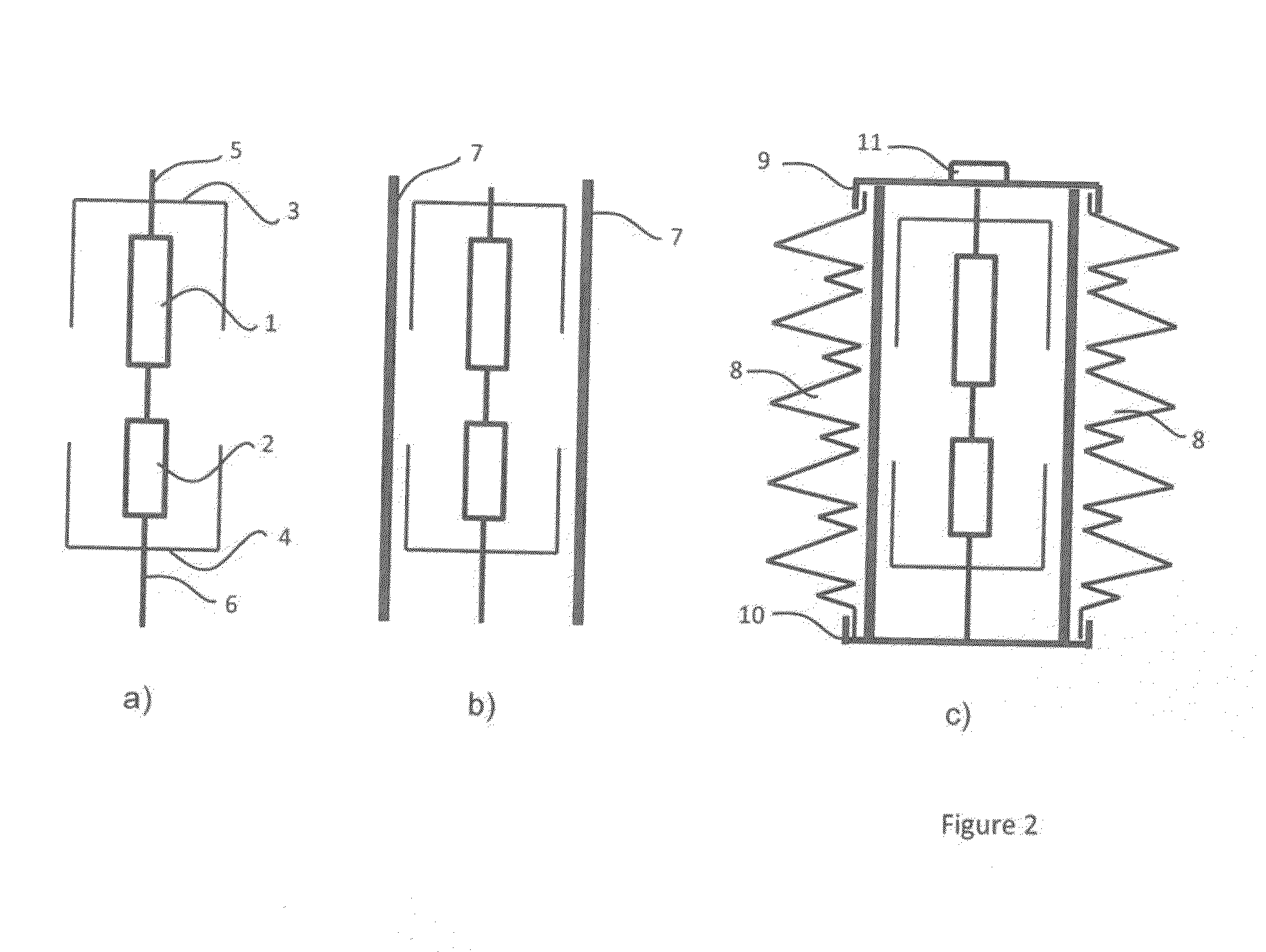

[0011]Structures for creepage distance enlargement are disclosed herein which can be used with a sensor housing in a very effective and easy way.

[0012]According to exemplary embodiments, the voltage divider can be arranged in a housing or in housing modules which is or are covered at least partly by at least one shrinking tube of insulating material such that the shrinking creepage distance enlarging structures are implemented at least at the outer surface of the shrinking tube.

[0013]In exemplary embodiments, a standard shrinking tube with sheds can be used, which is shrunken around a voltage divider module. This solution can provide significant cost saving in mold investments and reduction on sensor costs as well as significant reduction on manufacturing time of such solution.

[0014]Exemplary embodiments can reduce manufacturing time and effort and decrease production costs and investments needed for production. By using standard shrinking tube with sheds, which is shrunken around a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| voltage | aaaaa | aaaaa |

| creepage distance | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com