Turbo machine combustion assembly comprising an improved fuel supply circuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

[0056]According to the turbomachine, represented in FIG. 3a, the combustion chamber is of the preevaporation rod type, wherein each main injector 18 opens into a preevaporation rod 19, itself opening inside the chamber. Each pre-evaporation rod comprises a duct opening via two openings into the combustion chamber.

[0057]The pre-evaporation rods 19 enter the combustion chamber through an opening formed in the outer wall 14 or in the chamber end wall 16 of the combustion chamber 10, and having a Tshaped section, the ends of which are curved toward the chamber end wall.

second embodiment

[0058]According to the turbomachine, represented in FIG. 3b, the main injectors 18 are of aerodynamic or aeromechanical type, and directly enter the chamber 10 through an opening formed in the chamber end wall 16.

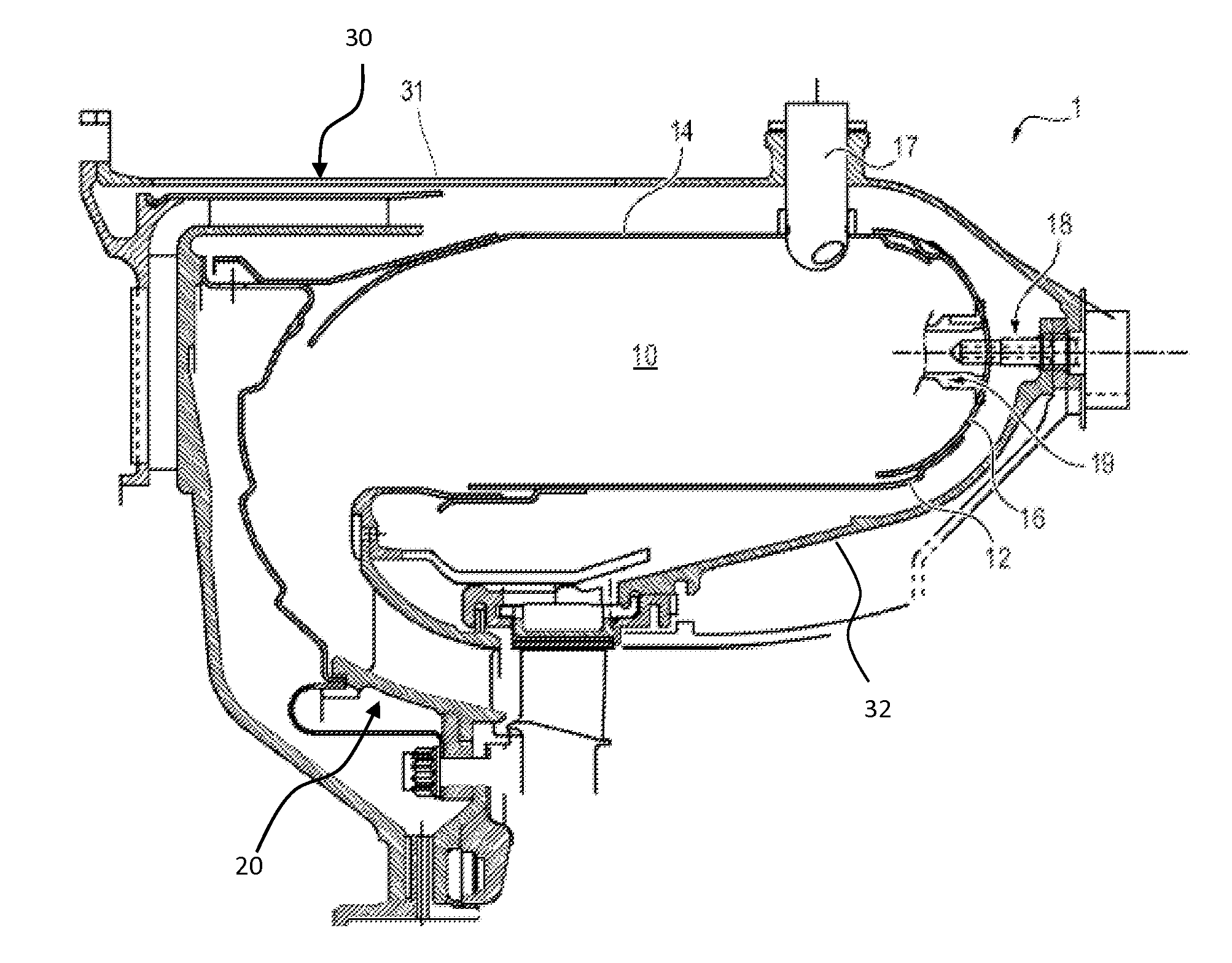

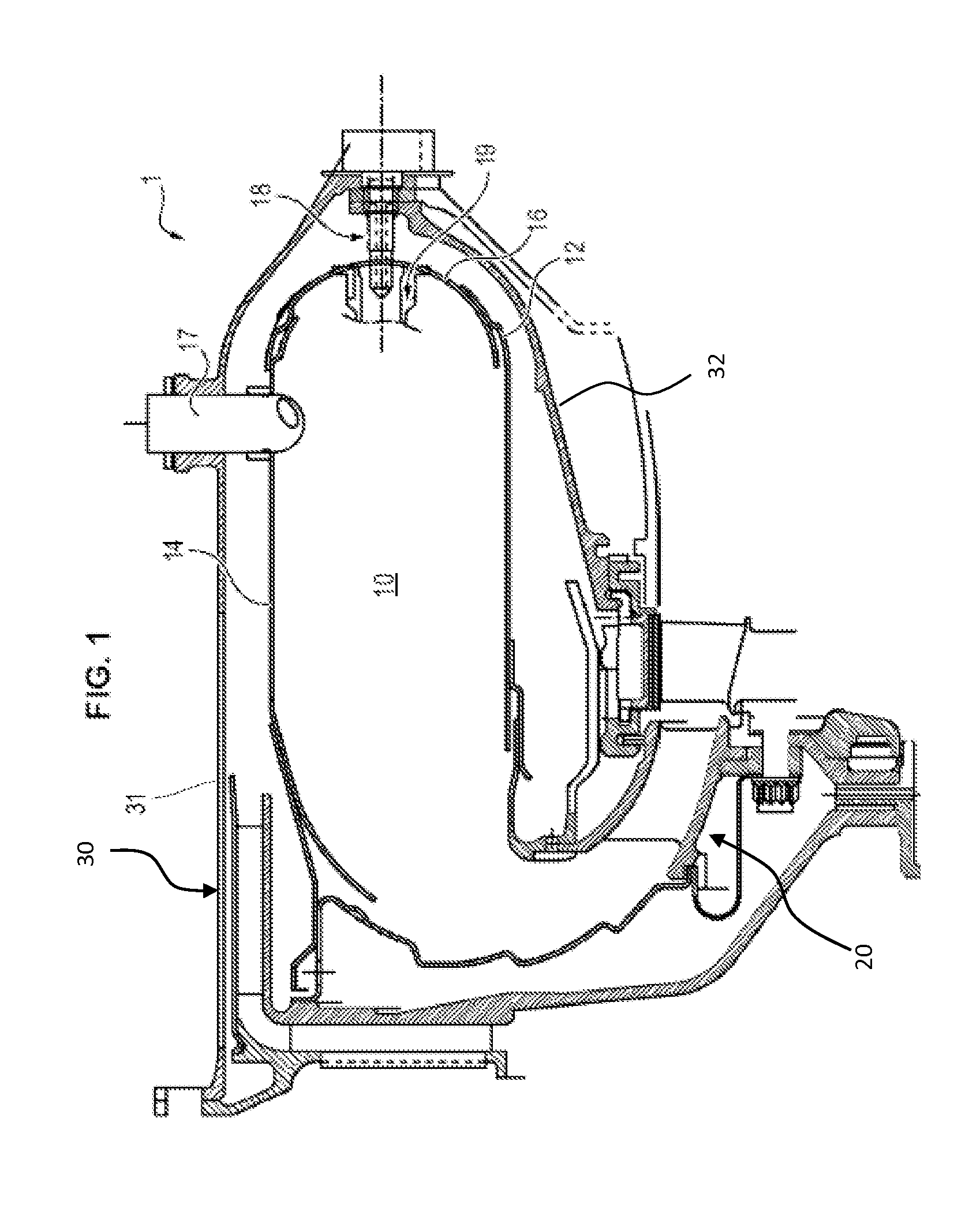

[0059]Advantageously, the combustion chamber is of reverse flow type.

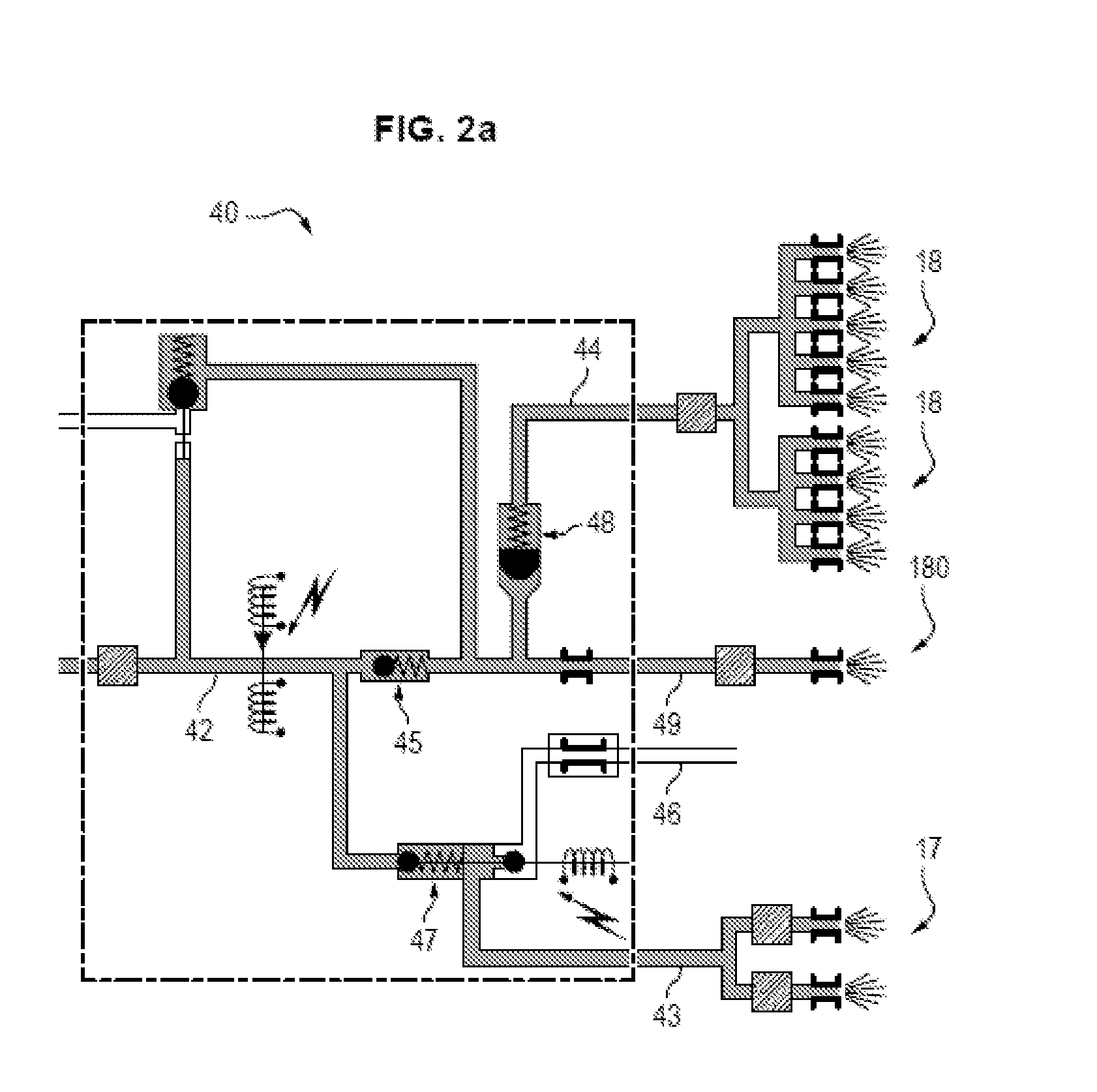

[0060]The turbomachine 1 also comprises a fuel supply circuit 40 for the injectors, said circuit being represented in FIG. 4.

[0061]The fuel supply circuit comprises a fuel injection inlet 41, by which the fuel enters the circuit along a fuel distribution duct 42.

[0062]The fuel distribution duct is connected to the starting injectors by a supply duct 43 for the starting injectors, and to the main injectors by a supply duct 44 for the main injectors.

[0063]The fuel supply circuit is designed to supply fuel to the starting injectors continuously, so that said injectors are supplied with fuel both during a step of initiating the combustion in which the fuel is set alight by the spark plug, and during the later ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com