Rocker cover assembly for engines

a technology for engine covers and fasteners, which is applied in the direction of machines/engines, propulsion by batteries/cells, and gearing. it can solve the problems of affecting the reliability of the assembly of the threaded fastener with the cover body and the cover plate, the wear and tear of the threaded bore of the cover body, and the loss of threaded fasteners

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

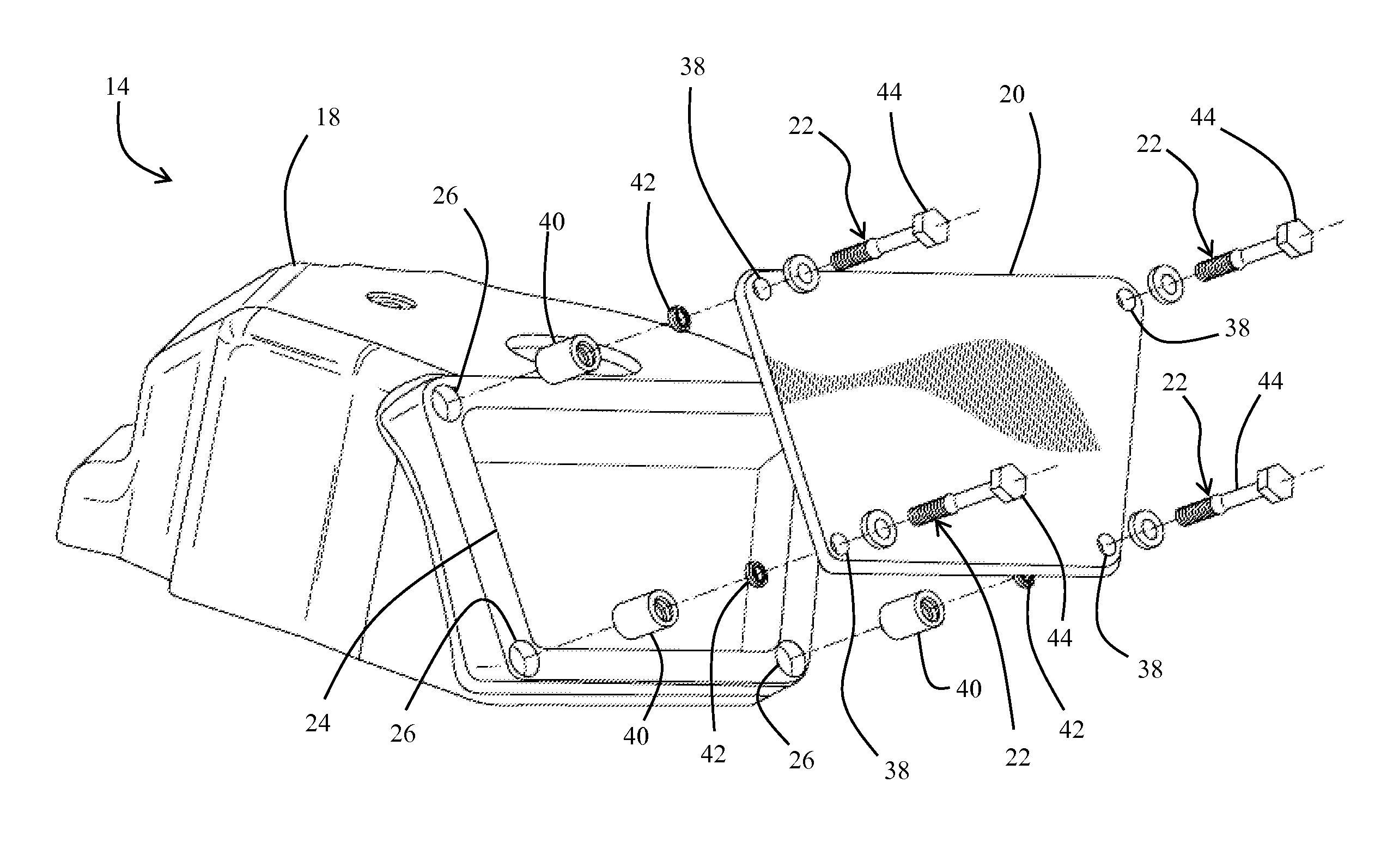

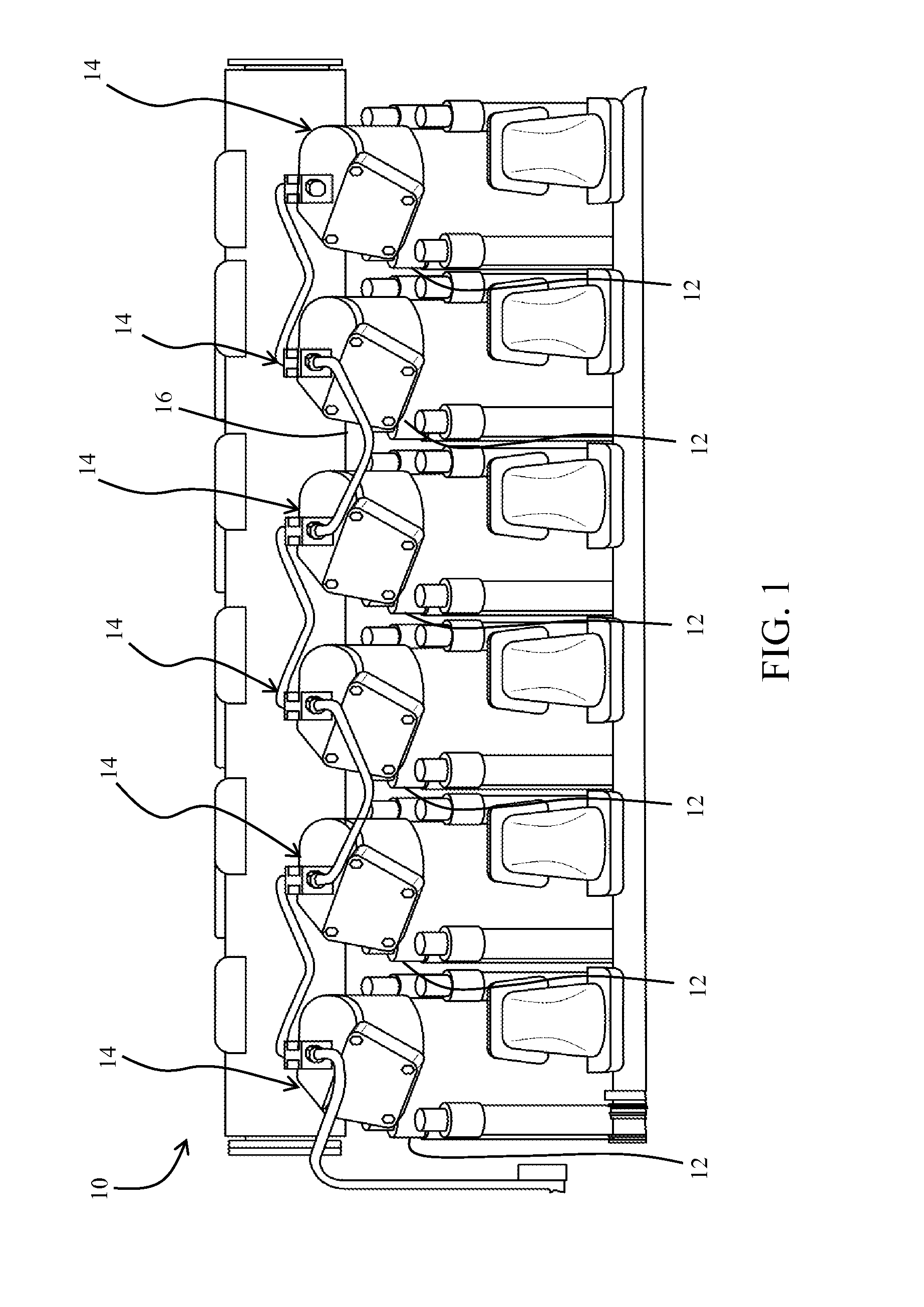

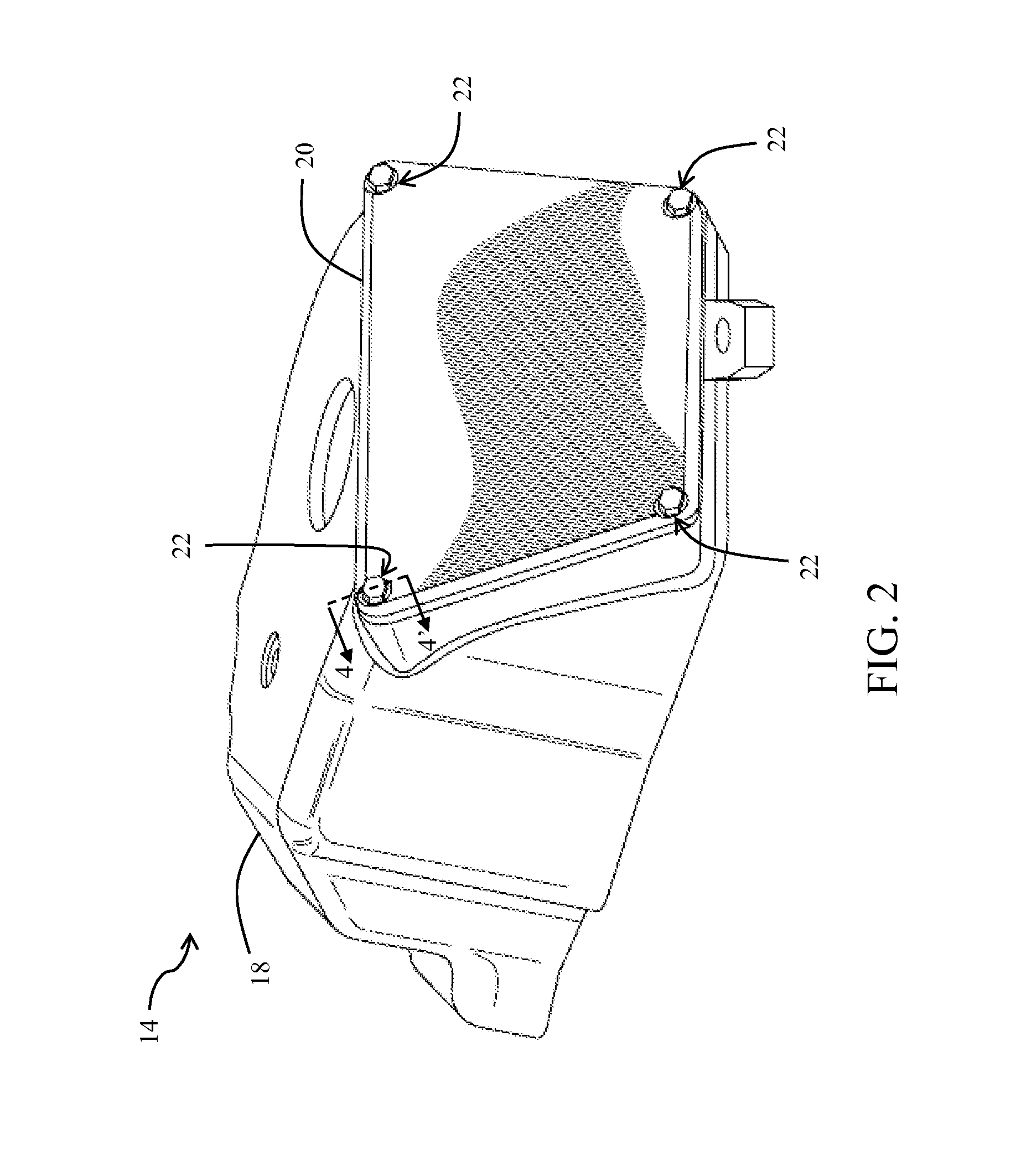

[0012]Referring to FIG. 1, there is shown an engine 10. Although not limited to, the engine 10 may be one of a spark ignition type and / or a compression ignition type. Other engine types may also be contemplated. Exemplarily, the engine 10 includes six in-line cylinders 12, each of which includes various mechanical components (not shown) arranged to perform one or more functions associated with the engine 10. The mechanical components (not shown) may include, but are not limited to, an intake valve, an exhaust valve, a rocker arm, and a rocker shaft. Additionally, the engine 10 employs six rocker cover assemblies 14, which co-relate to each of the six cylinders 12, and each of which is adapted to cover and protect the mechanical components (not shown) of each of the six cylinders 12 of the engine 10. More specifically, a rocker cover assembly 14 is mounted onto an engine block 16, such that the rocker cover assembly 14 covers the mechanical components (not shown) of a cylinder 12 of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com