Climate control systems and methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Method of Quad-Generation for Control of an Indoor Agricultural Plant

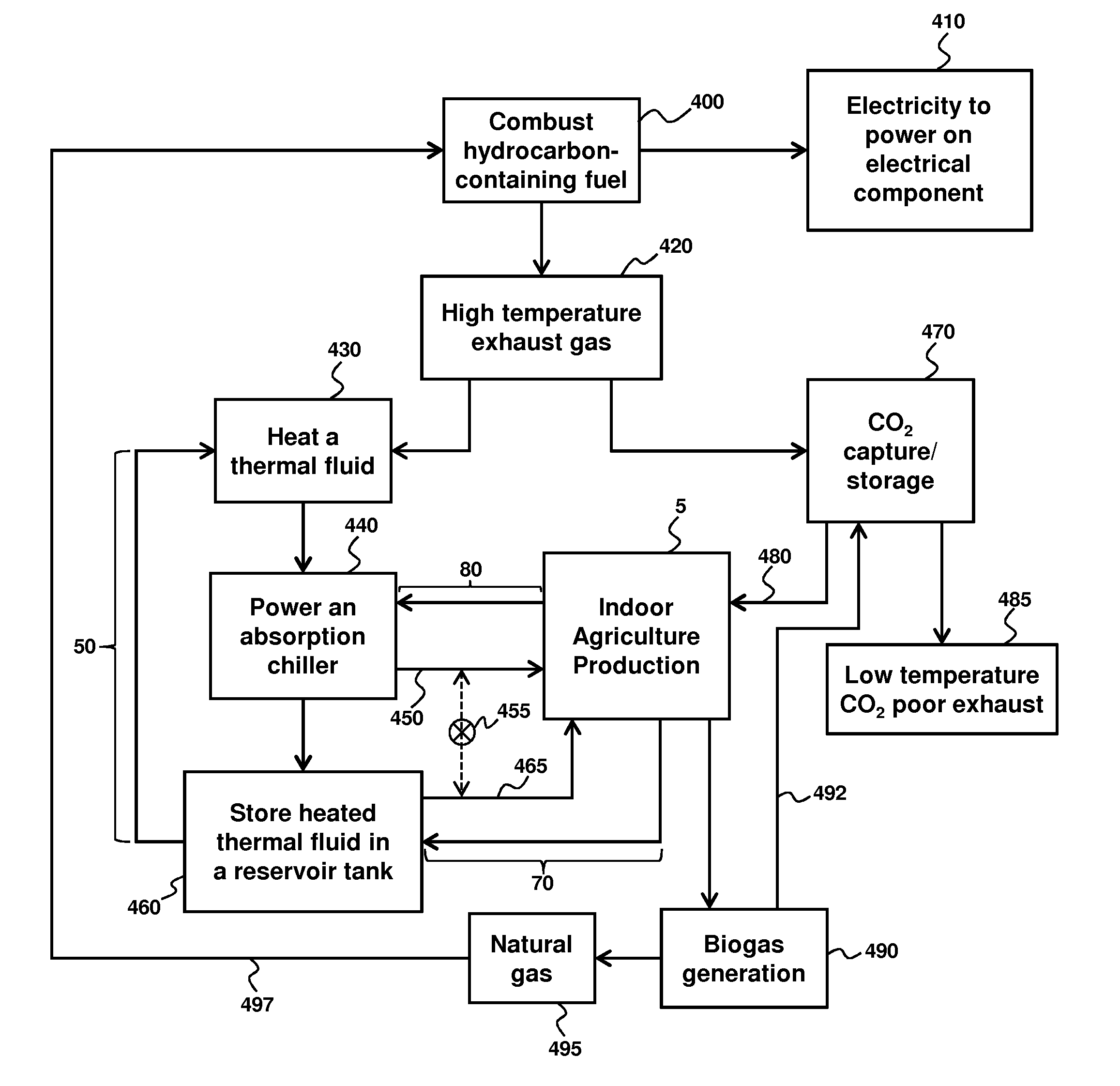

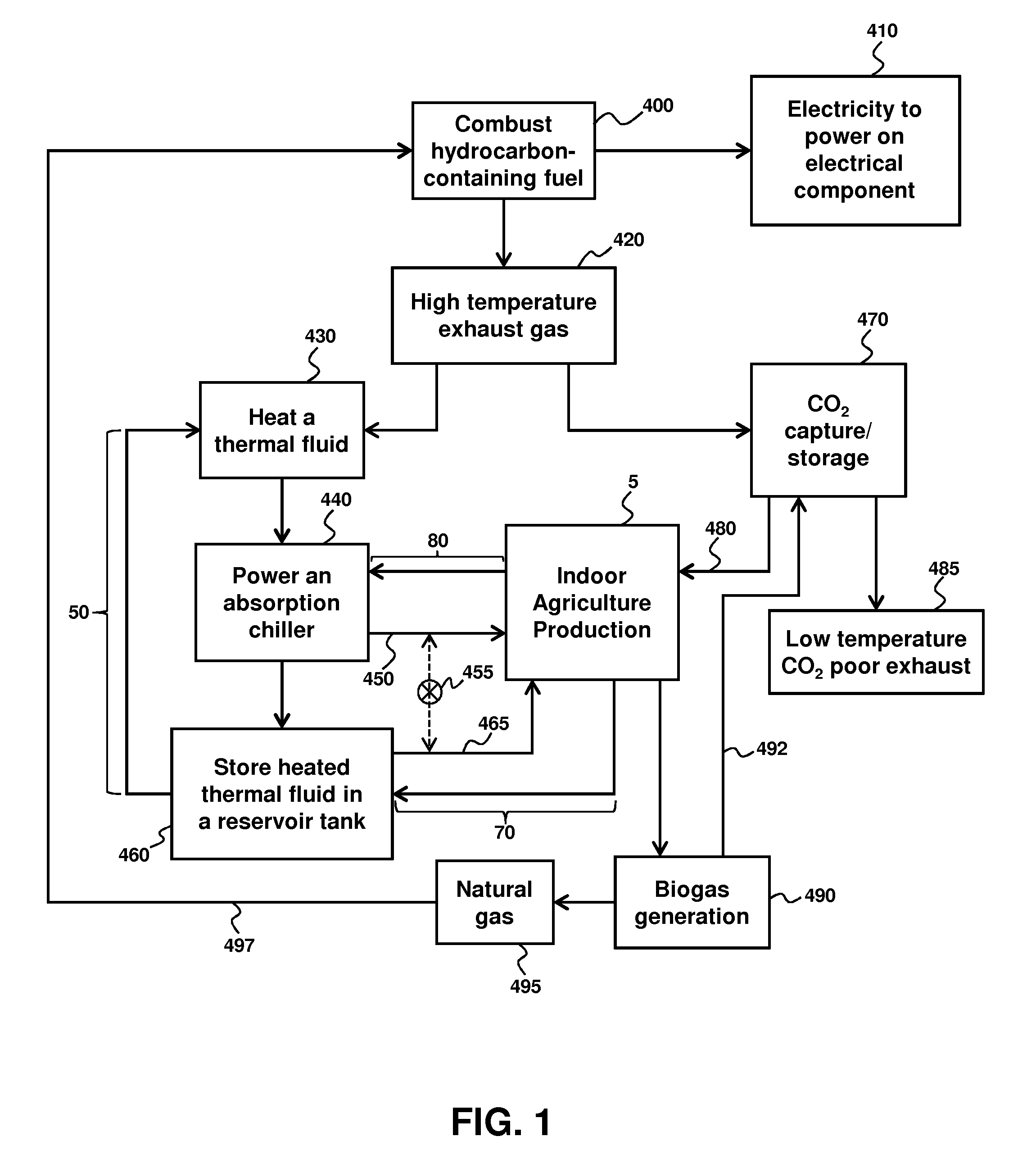

[0081]FIG. 1 is a process flow diagram summary of one method of the instant invention. A hydrocarbon-containing fuel is combusted 400 to generate electricity to power 410 one or more electrical components and to generate a high temperature exhaust gas stream 420 that is used to heat a thermal fluid 430. The electrical component may be located in the enclosed space or outside the enclosed space. The heated thermal fluid is then used to power an absorption chiller 440 which generates a cooled thermal fluid 450 which can be introduced to an enclosed space 5 such as indoor agriculture production plant in a chilled thermal fluid loop 80. The chilled thermal fluid loop then provides a return of thermal fluid from the enclosed space to the absorption chiller where the cooled thermal fluid step 450 may be repeated. In the meantime, heated thermal fluid that exits the absorption chiller may be stored in a reservoir tank 460...

example 2

Climate Control Systems

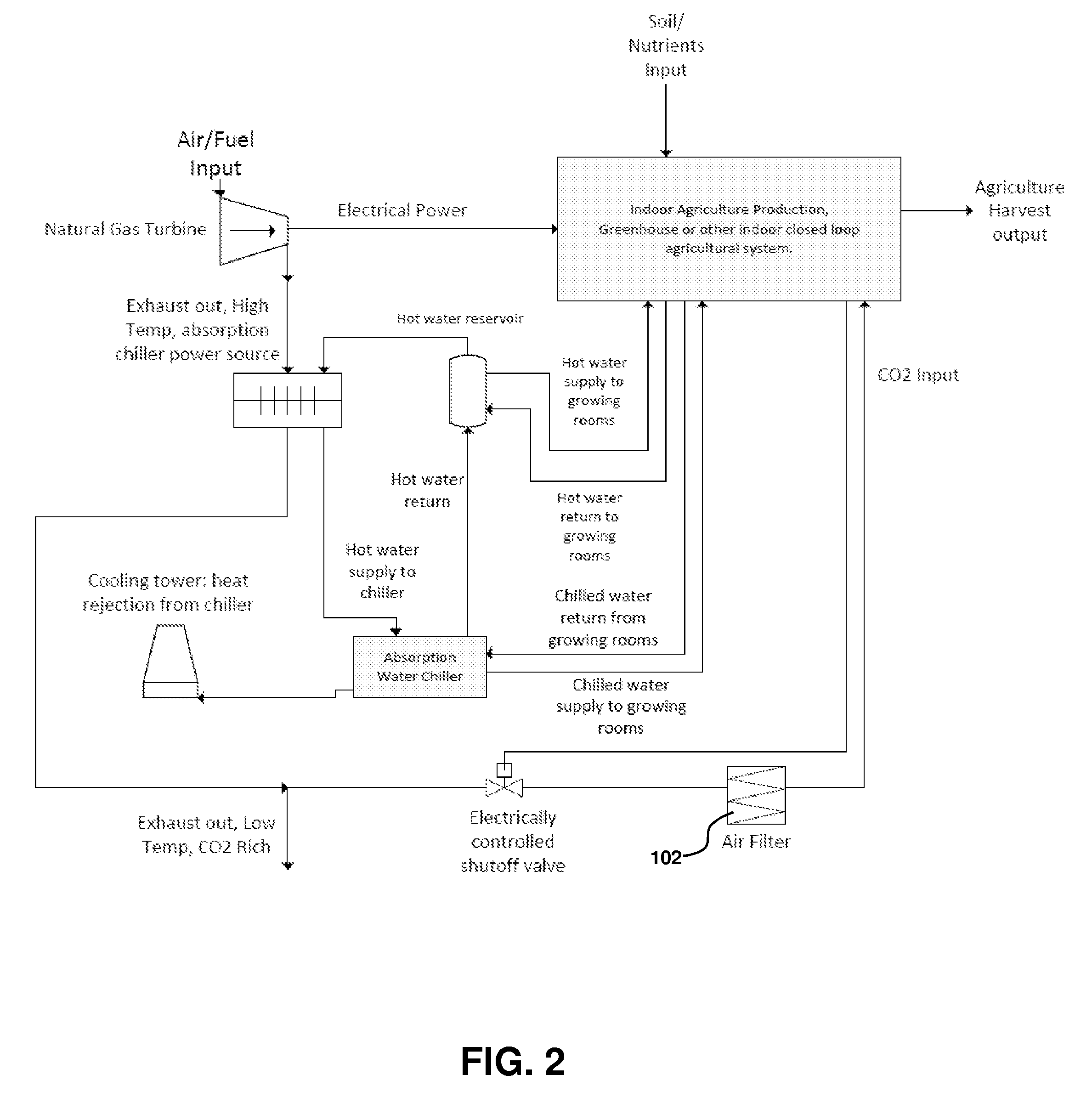

[0084]FIGS. 2-3 are schematic illustrations of two embodiments of a climate control system that provides generation and control of four aspects, specifically electricity, heat, cooling and CO2 levels. FIGS. 2 and 3 are similar with a general difference that FIG. 3 illustrates the option of biogas generation to further improve efficiency and environmental sustainability.

[0085]Enclosed space 5 is illustrated as having a number of inputs for indoor agricultural production, including soil 6 and nutrient input 7 (e.g., fertilizers and the like), as well as an agricultural harvest output 8. Other relevant inputs are the subject of the instant invention and include electrical 20, heating 76, cooling 88 and CO2 112, as explained herein below.

[0086]A hydrocarbon-fueled electrical power generator 10 provides electrical power such as by electrical power line 20. The electrical power line 20 is illustrated as connected to enclosed space 5 and may be used, for example, to ...

example 3

Absorption Chiller

[0097]Absorption chiller 60 is an energy efficient manner to obtain chilled thermal fluid in an indirect manner, wherein heated thermal fluid is used to drive chilling of a thermal fluid for subsequent cooling control. A cooling tower 62, connected to the absorption chiller via cooling tower inlet line 64 and cooling tower outlet line 66, provides additional temperature control in the absorption chiller. FIG. 4 further illustrates one example of an absorption chiller for use with the methods and systems summarized in FIGS. 1-3. Heated thermal fluid 42 from heat exchanger 40 is provided to the absorption chiller, such as in the form of steam / hot water at about 220° F.-260° F. as indicated by inlet arrow 42. The thermal fluid is then removed from the absorption chiller as indicated by outlet arrow 44, with 42 and 44 corresponding to conduits 42 and 44 of FIG. 3 and that may form part of thermal recirculating fluid loop 70. Similarly, arrows 830 and 840 refer to a chi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com