Thermal engine using noncombustible fuels for powering transport vehicles and other uses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first preferred embodiment

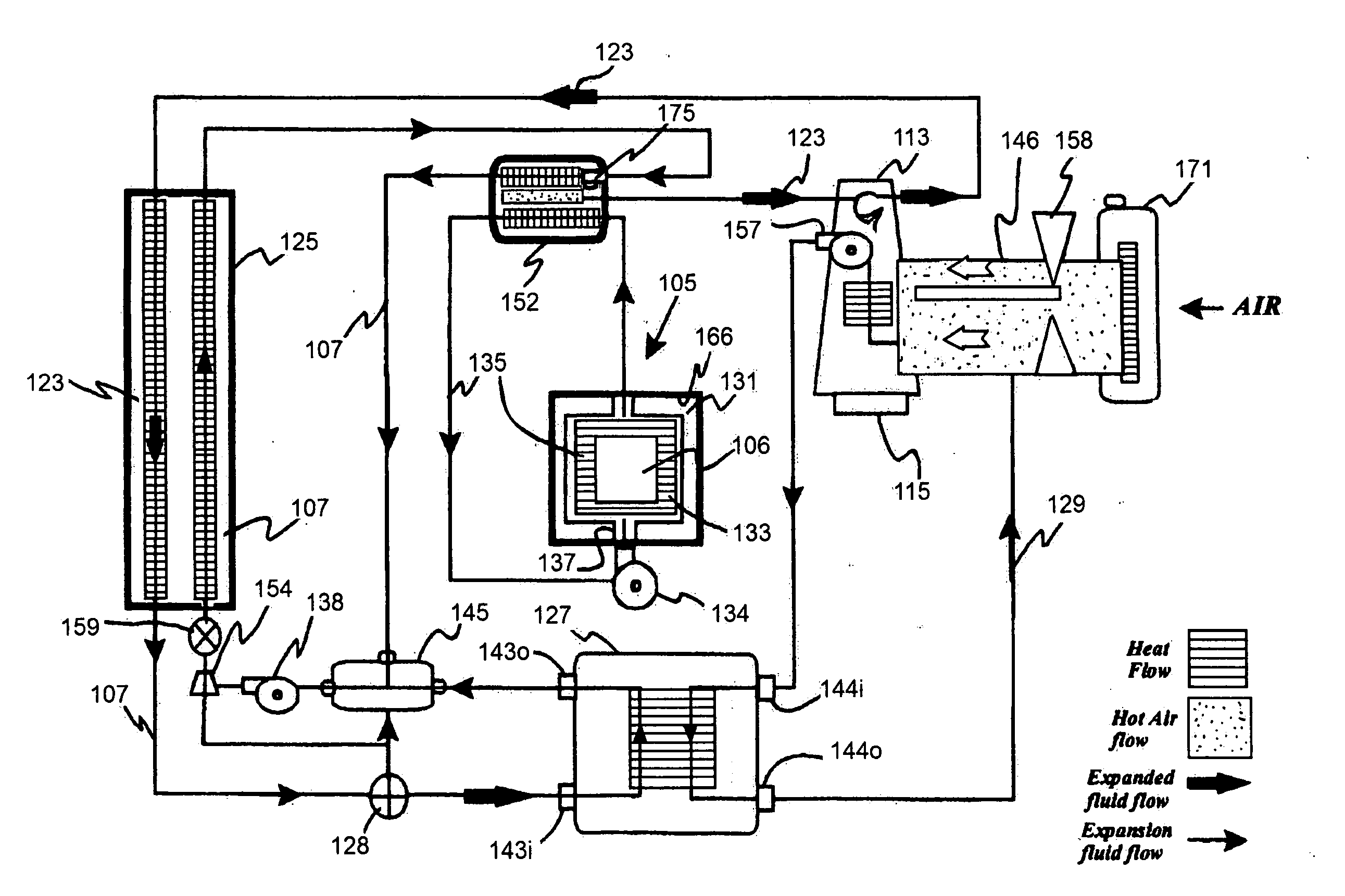

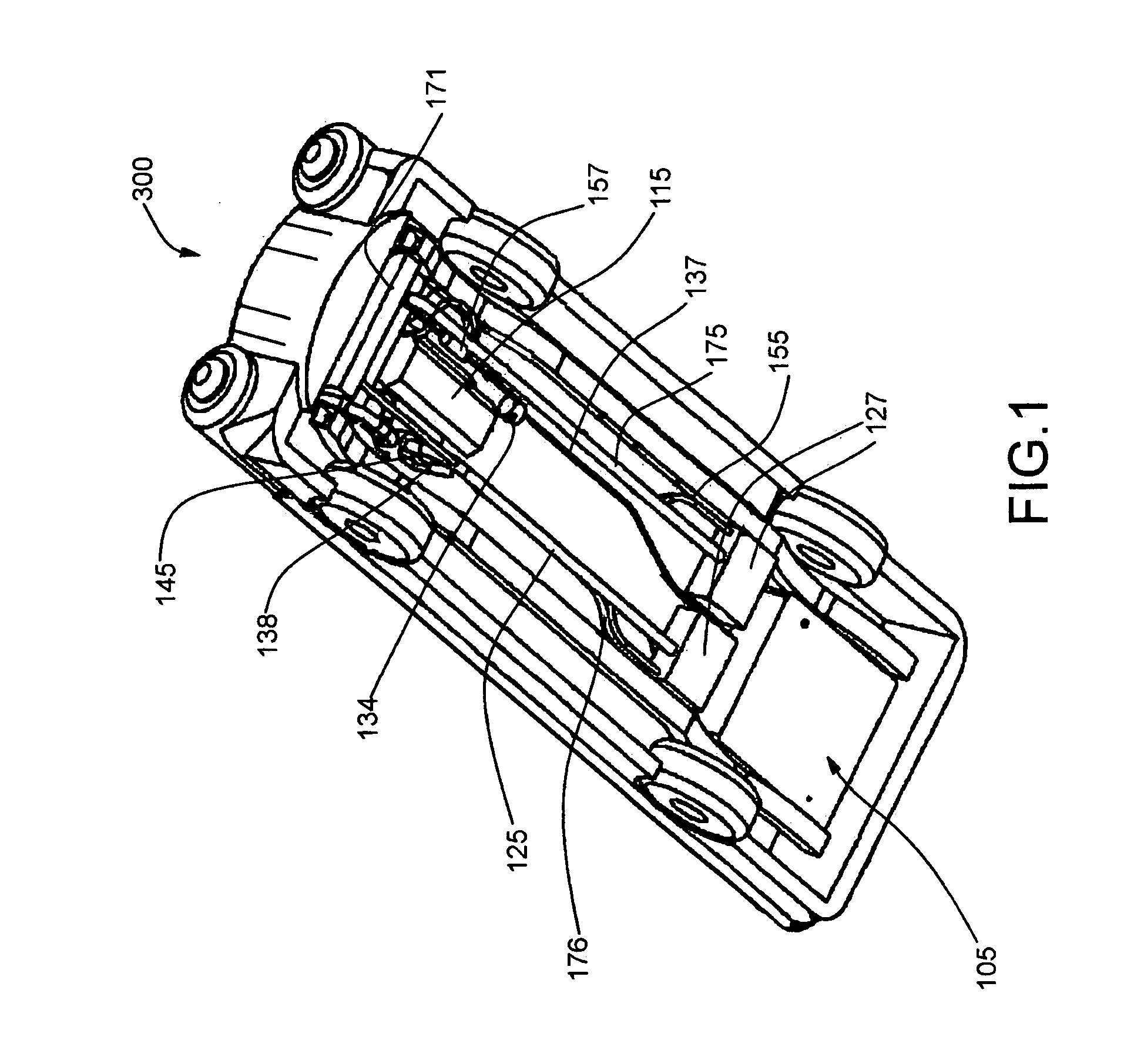

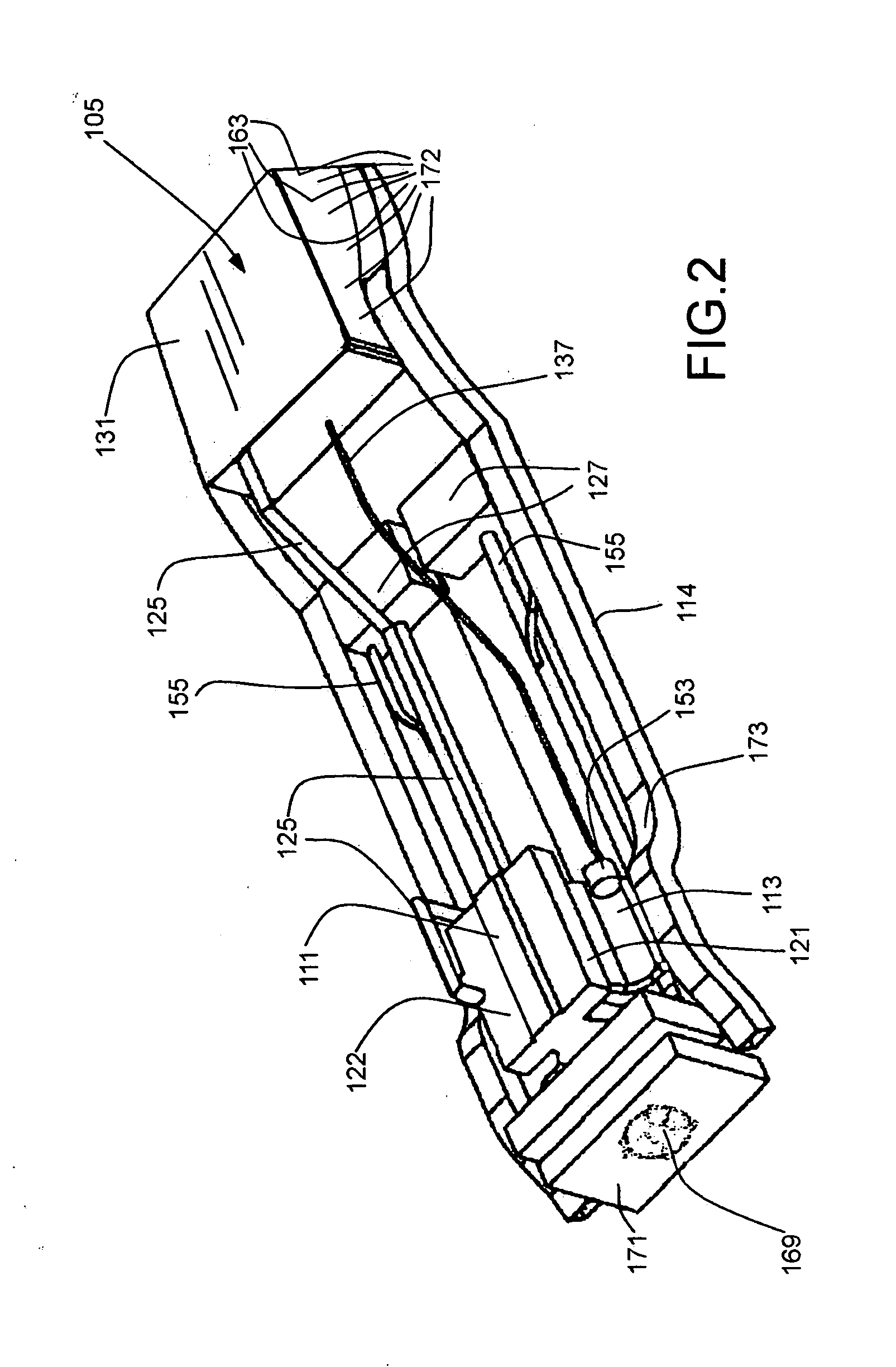

[0120]The present invention relates generally to the field of engines that convert heat into mechanical energy. Referring to FIGS. 1-12, a thermal engine 100 is disclosed which may be used to power a vehicle 300 such as a car or a Train. Thermal engine 100 uses the thermodynamic properties of an expansion fluid 107 and the pressure it generates during phase change to expanded fluid 145 to convert thermal energy to mechanical energy.

[0121]In its most basic form, as mentioned above generally, the thermal engine 100 incorporates several conventional engine elements including valve cover 111 sealingly mated to valve block 112 sealingly mated to engine block 113 and with a crankcase 114 sealingly mated to sump 115. These components of the thermal engine 100 could be injection molded from suitable engineering plastics and ceramic composites and appropriately lined with durable inserts in areas where wear might be a problem.

[0122]The engine block 113 has one or more longitudinal spaced cyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com