Practical Alternative Microwave Technology to Enhance Recovery Heavy Oil in Reserviors

a technology of heavy oil and microwave energy, which is applied in the field of extraction of heavy oil, can solve the problems of increasing reliability, reducing maintenance in the long run, and limited maneuverability, and achieves the effects of reducing the viscosity of tar sand, and heating up the trapped water embedded in tar sand or oil shale very quickly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

of FIGS. 1-3

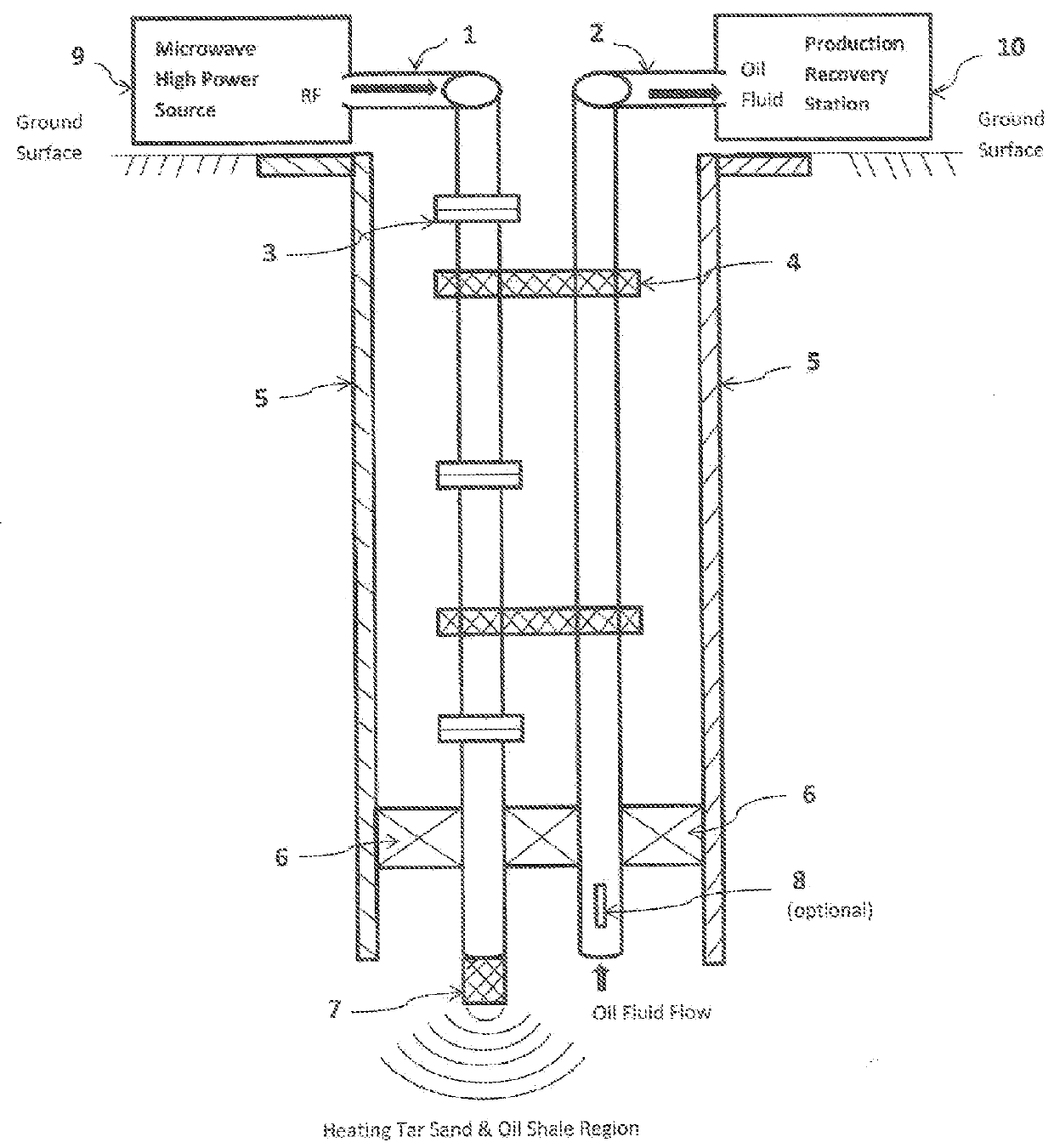

[0027]It is understood that the frequency at 2.450 Gigahertz is where the water resonates and absorbs highest microwave radiation energy at microwave frequency spectrum; heating water to boiling temperature in order to break down heavy oil in reservoir. It is also understood that the tar sand and oil shale have certain permittivity and attenuation values at microwave frequency that significant enough to absorb microwave power heating up the hydrocarbon and breaking down heavy oil viscosity to lighter viscosity. This invention is focus on these ideas and developed a practical alternative microwave enhancement method for better recovery in heavy oil reservoirs from tar sand and oil shale in deep reservoirs, much cleaner and friendlier for earth environment.

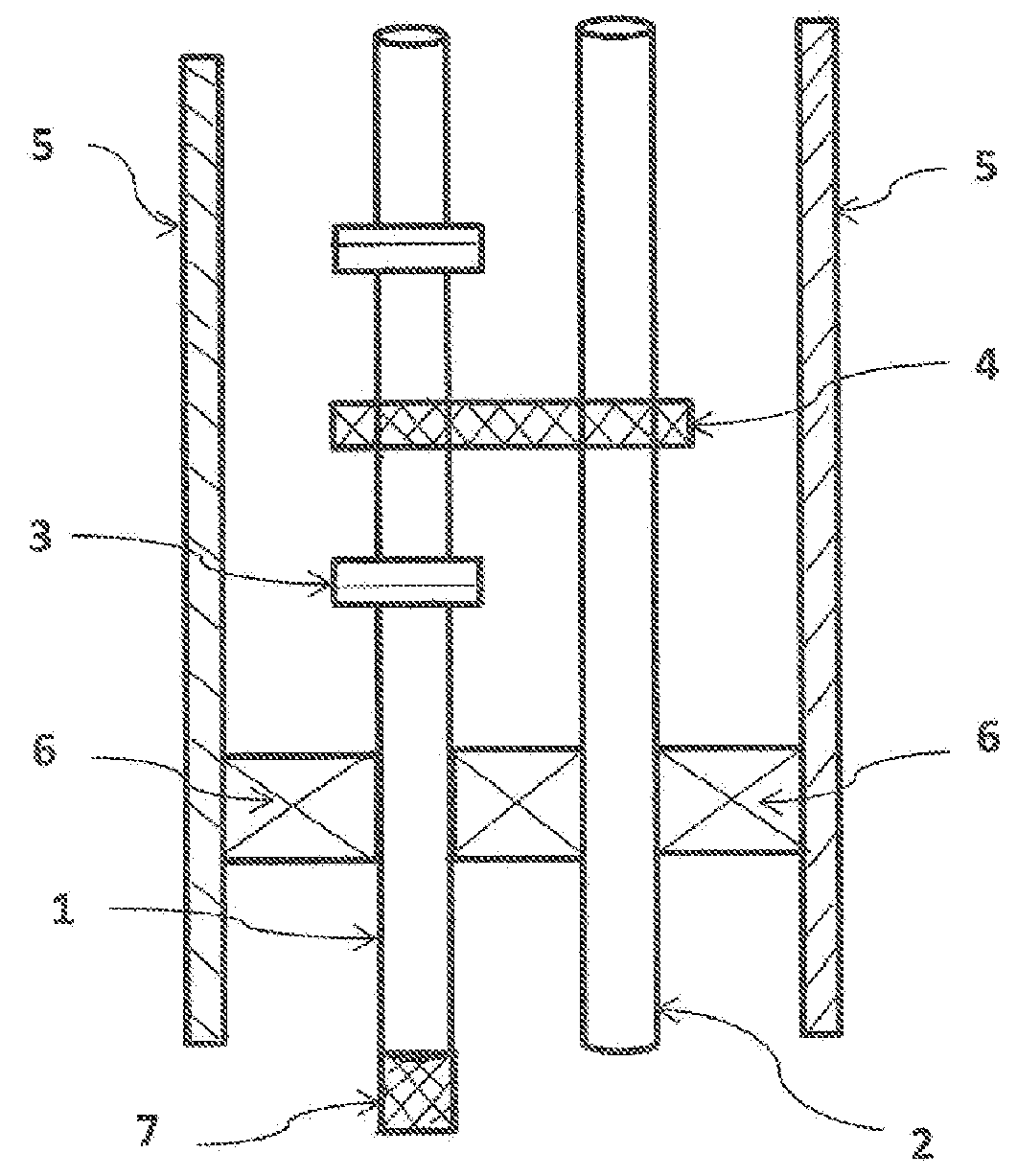

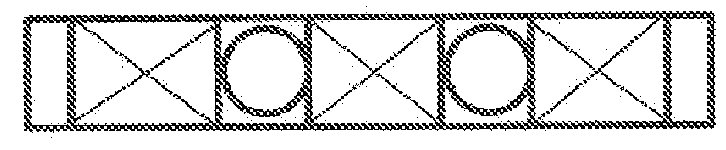

[0028]FIG. 1 shows the front view invention illustration of a microwave circular waveguide pipe 1 and a production recovery pipe 2 inside of well borehole casing 5. Both pipes run from the above ground surface down into ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com