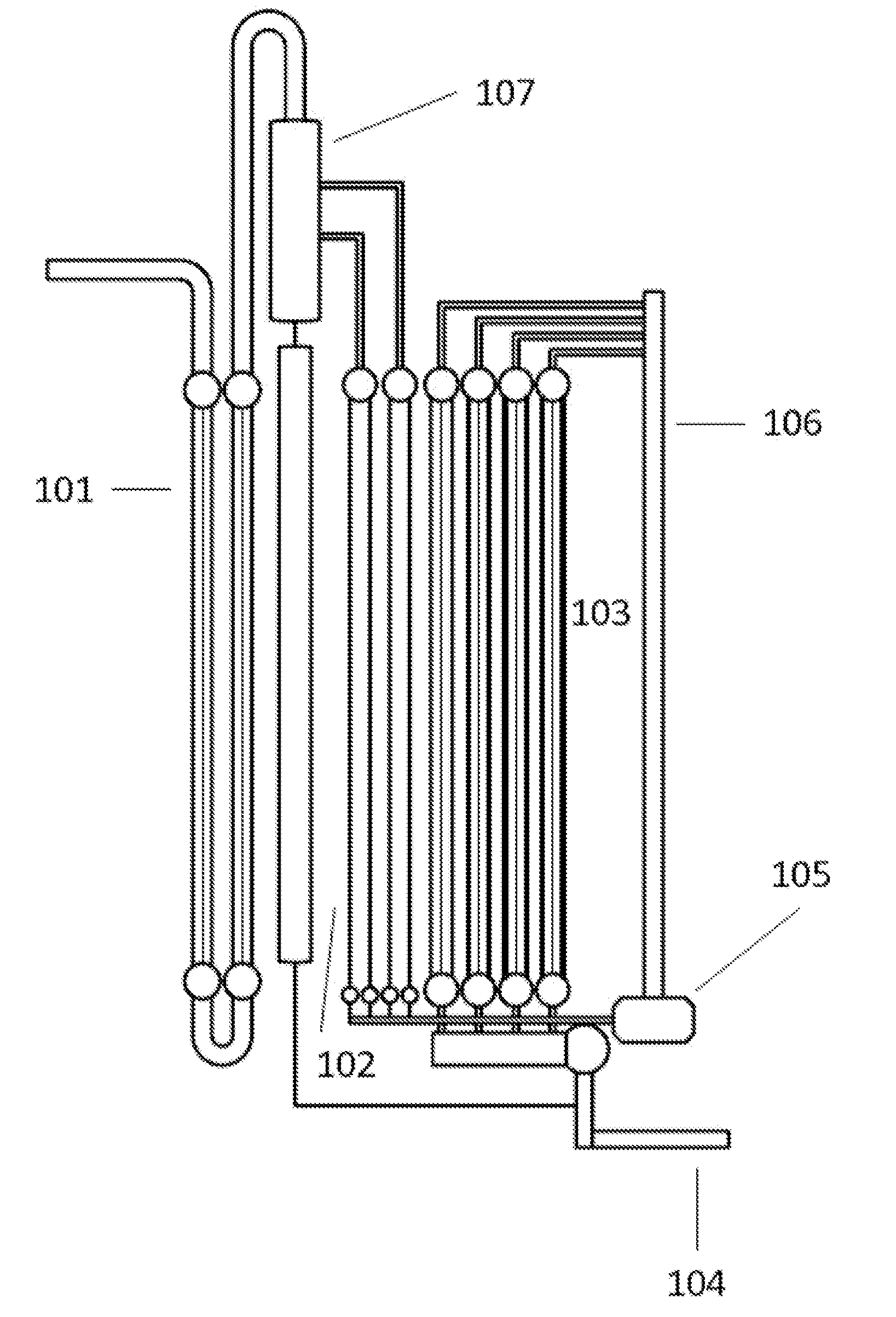

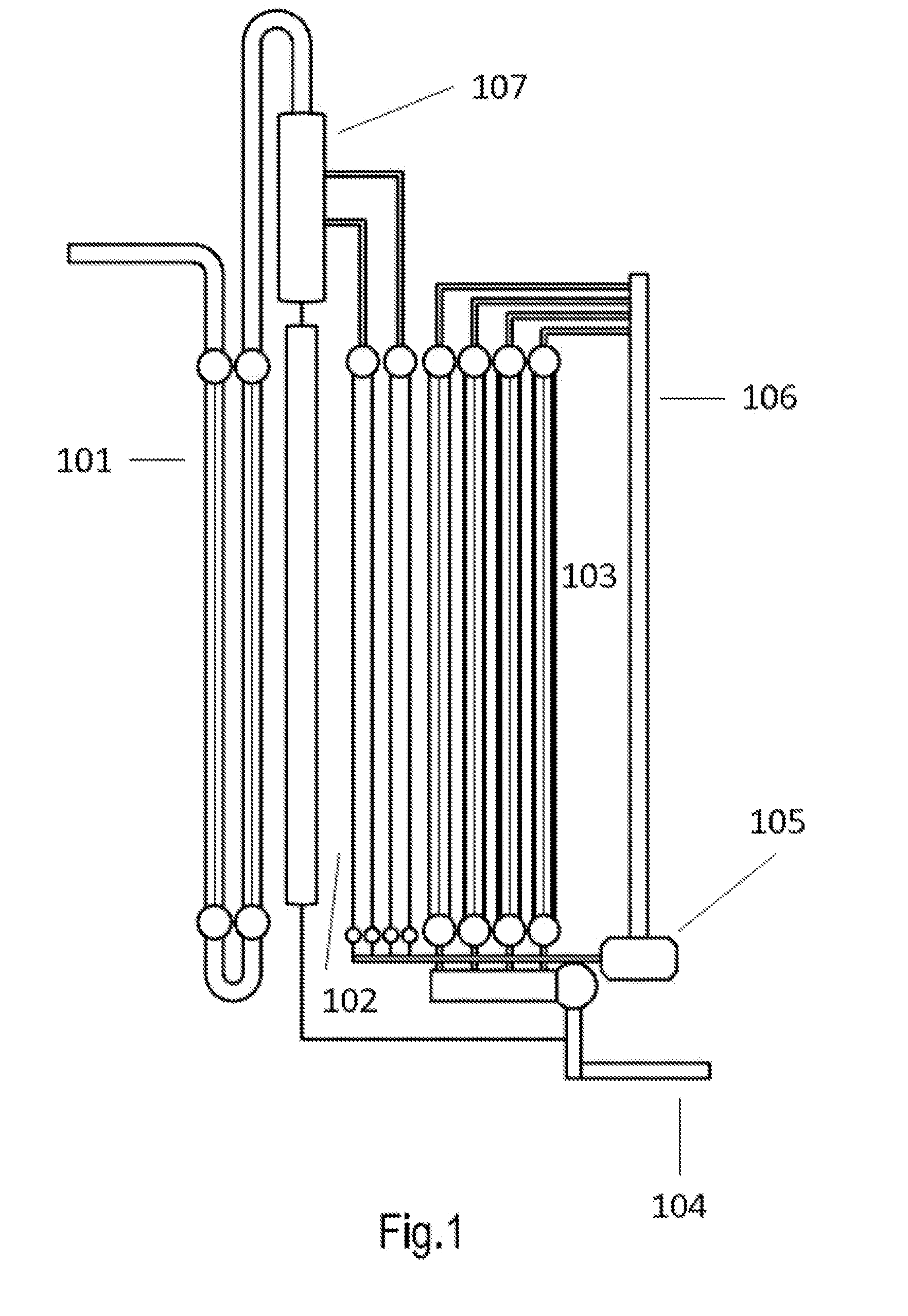

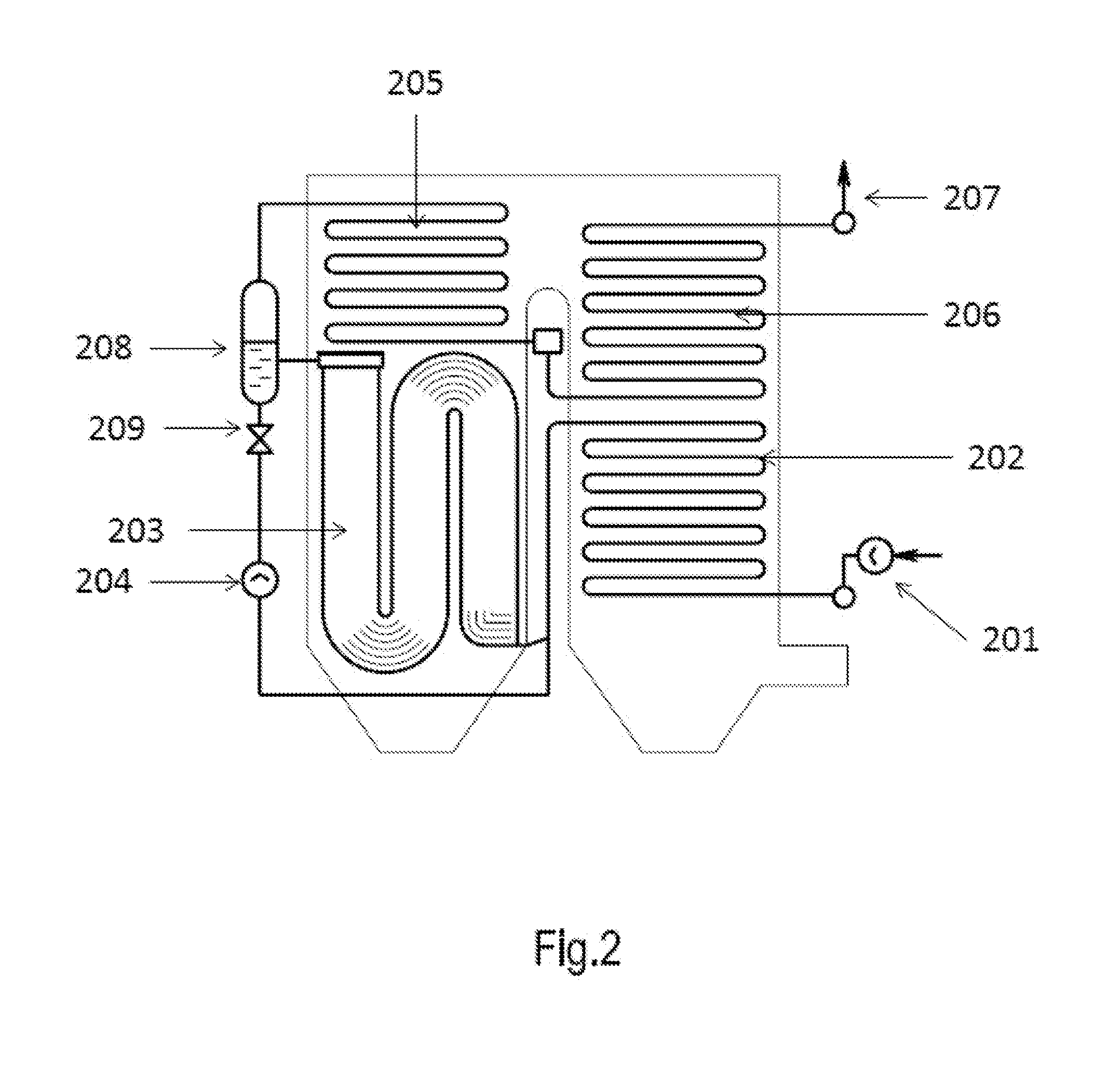

Vertical multiple passage drainable heated surfaces with headers-equalizers and forced circulation

a technology of forced circulation and drainable heated surfaces, applied in the field of heated surfaces, can solve problems such as reducing corrosion, and achieve the effects of improving the stability of flow and temperature regime of tubes, increasing steam/water mass velocity, and reducing multivalues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019]All types of thermal power plants are emitting a lot of waste heat into the atmosphere. To improve the thermal efficiency and decrease carbon dioxide emissions a noticeable portion of waste heat can be captured and used for the different goals. Let's consider the issue in the context of Combine Cycle Power Plants (CCPP) as one of the most effective cycles in power industry. In this case the heat of exhaust gas after gas turbines (GT) can be used in heat recovery steam generators. The steam after HRSG goes into steam turbine (ST) which drives electrical generator. The thermal efficiency of such combined cycle (Brayton and Rankine cycles) can be above 60%. In contrast a single ST cycle of subcritical pressure is limited around 40%, the best modern GTs have thermal efficiency about 45%. The modern units with ST cycle of supercritical pressure have achieved 43-44%. In this respect the future tendency in this branch of power industry should be the CCPP with HRSG of supercritical pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com