Exhaust gas treatment system

a technology for exhaust gas treatment and exhaust gas, applied in exhaust treatment, nitrous oxide capture, climate sustainability, etc., can solve problems such as negative environmental effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

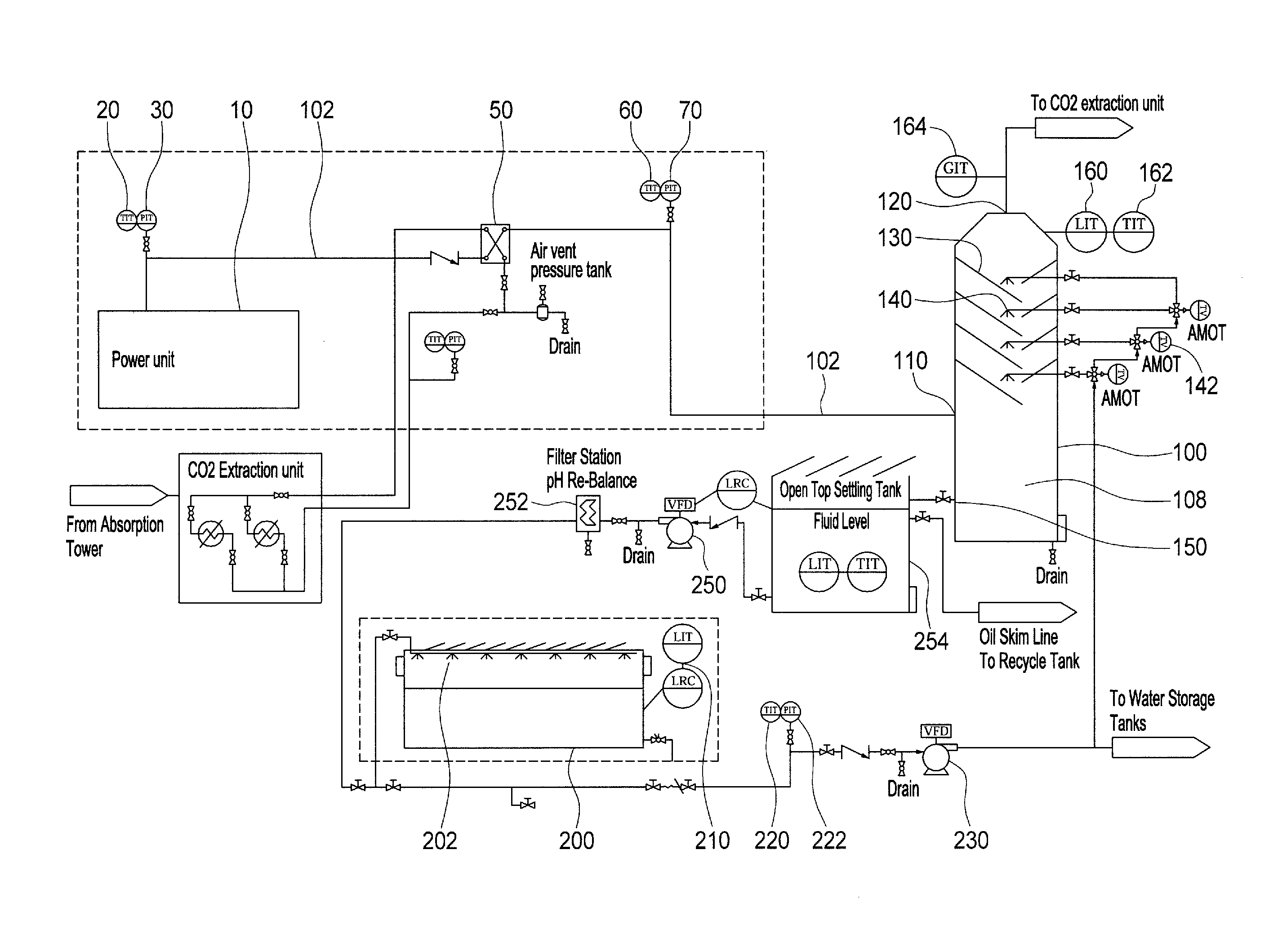

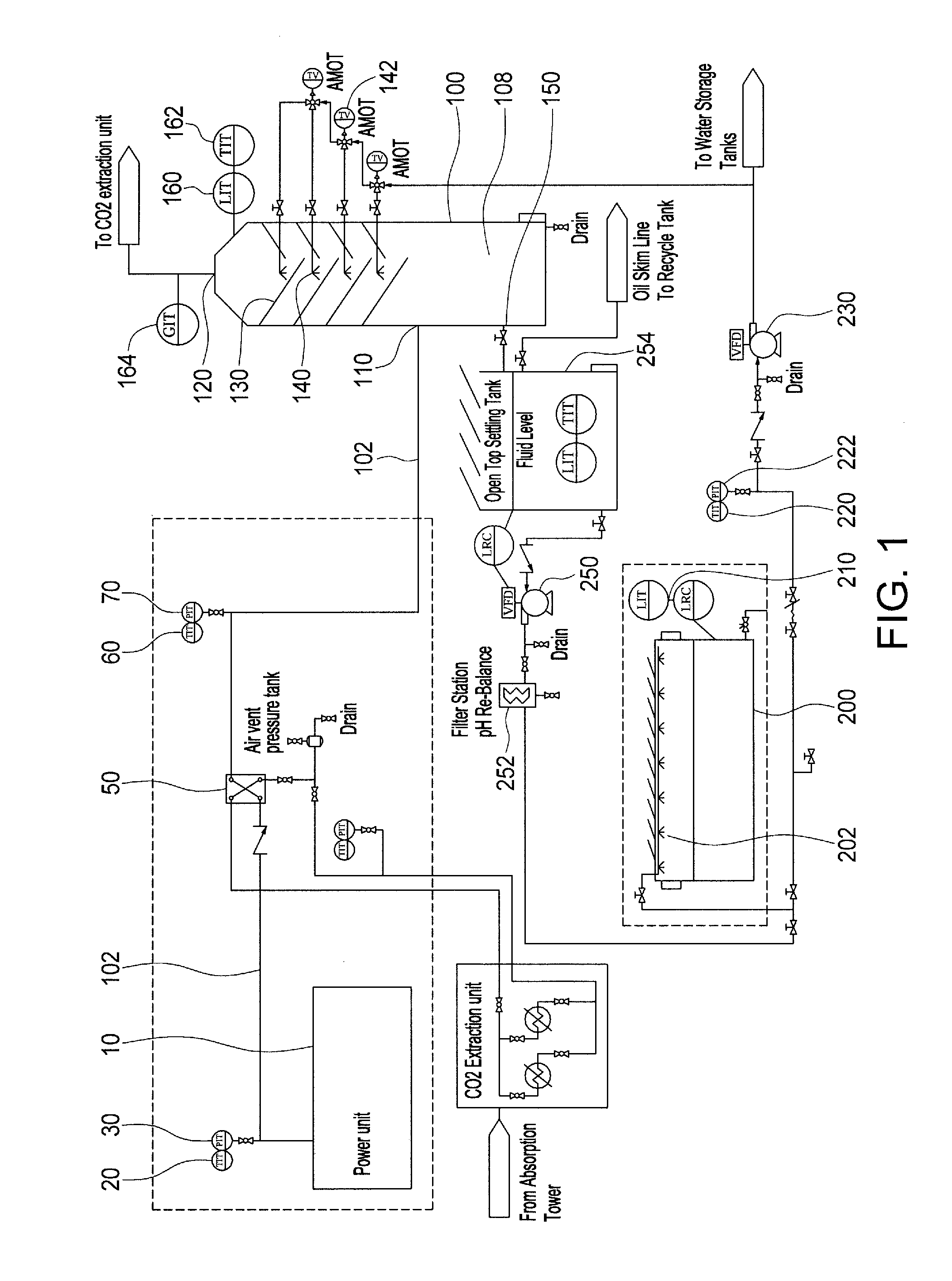

[0008]FIG. 1 illustrates a system for treating exhaust gases produced by one or more stationary combustion engines 10 that are used to produce electricity. Each stationary combustion engine 10 could be fueled by a range of acceptable fuels, but in one aspect each combustion engine 10 is fueled by natural gas. The system can capture the entire exhaust stream, remove contaminants from the exhaust stream and convert some of the output into transportable liquid products containing contaminants from the exhaust stream.

[0009]In the system, all of the exhaust gases from the one or more stationary combustion engines 10 are routed through at least one exhaust conduit 102 to an absorption tower 100 where the exhaust gas is treated. In an interior 108 of the absorption tower 100, the exhaust gas is allowed to pass upwards inside the absorption tower 100 as water is being sprayed on perforated plates 130 in the rising exhaust gas creating a chemical reaction binding the pollutants in the exhaus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com