Touch sensitive device comprising electroactive film, display device comprising the same, and method of manufacturing the electroactive film

a technology of electroactive film and touch sensitive device, which is applied in the direction of manufacturing tools, instruments, other domestic objects, etc., can solve the problems of ferroelectric polymers and conventional dielectric elastomers that are difficult to use, and achieve excellent dielectric constant, low light transmittance, and high light transmittance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

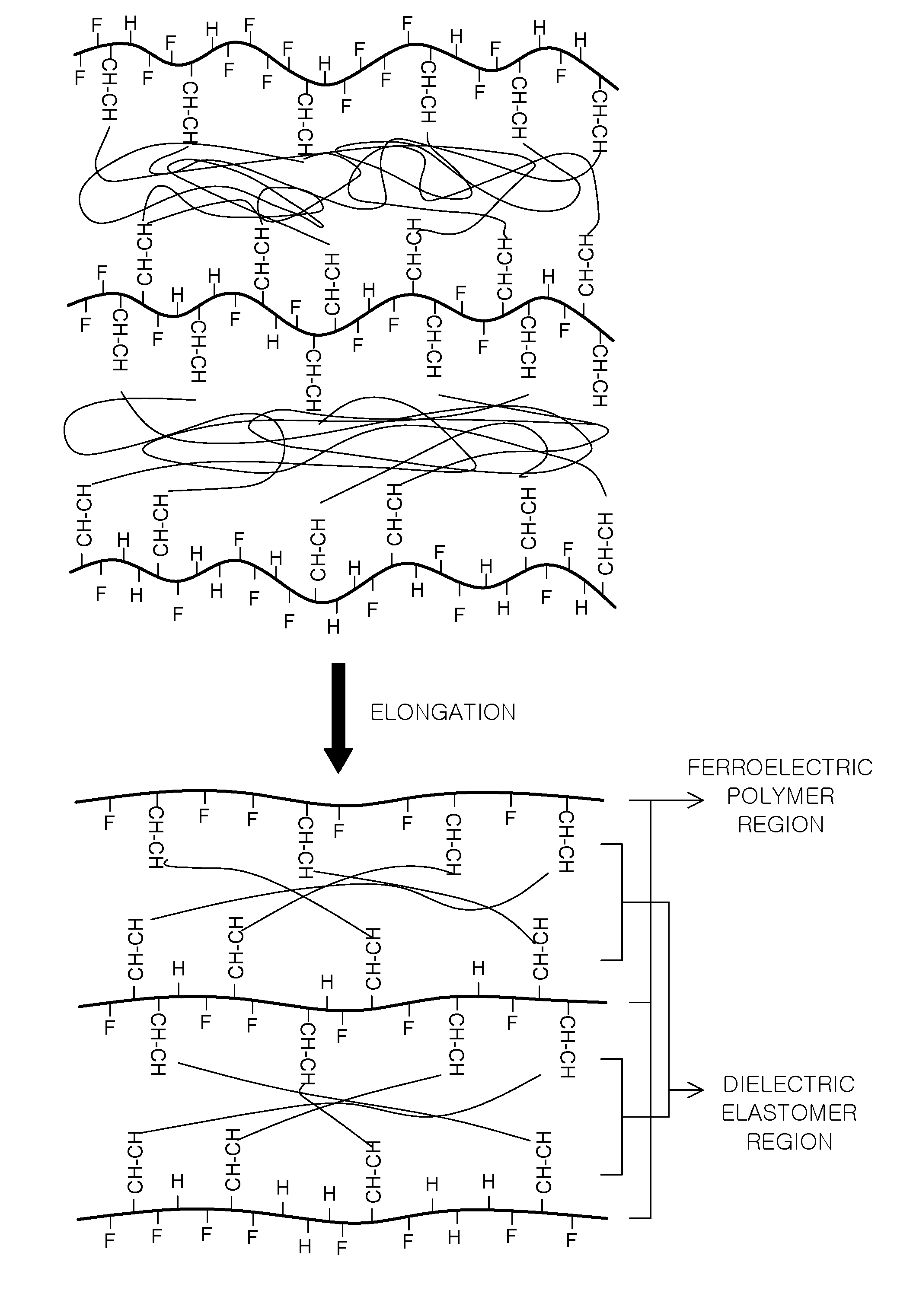

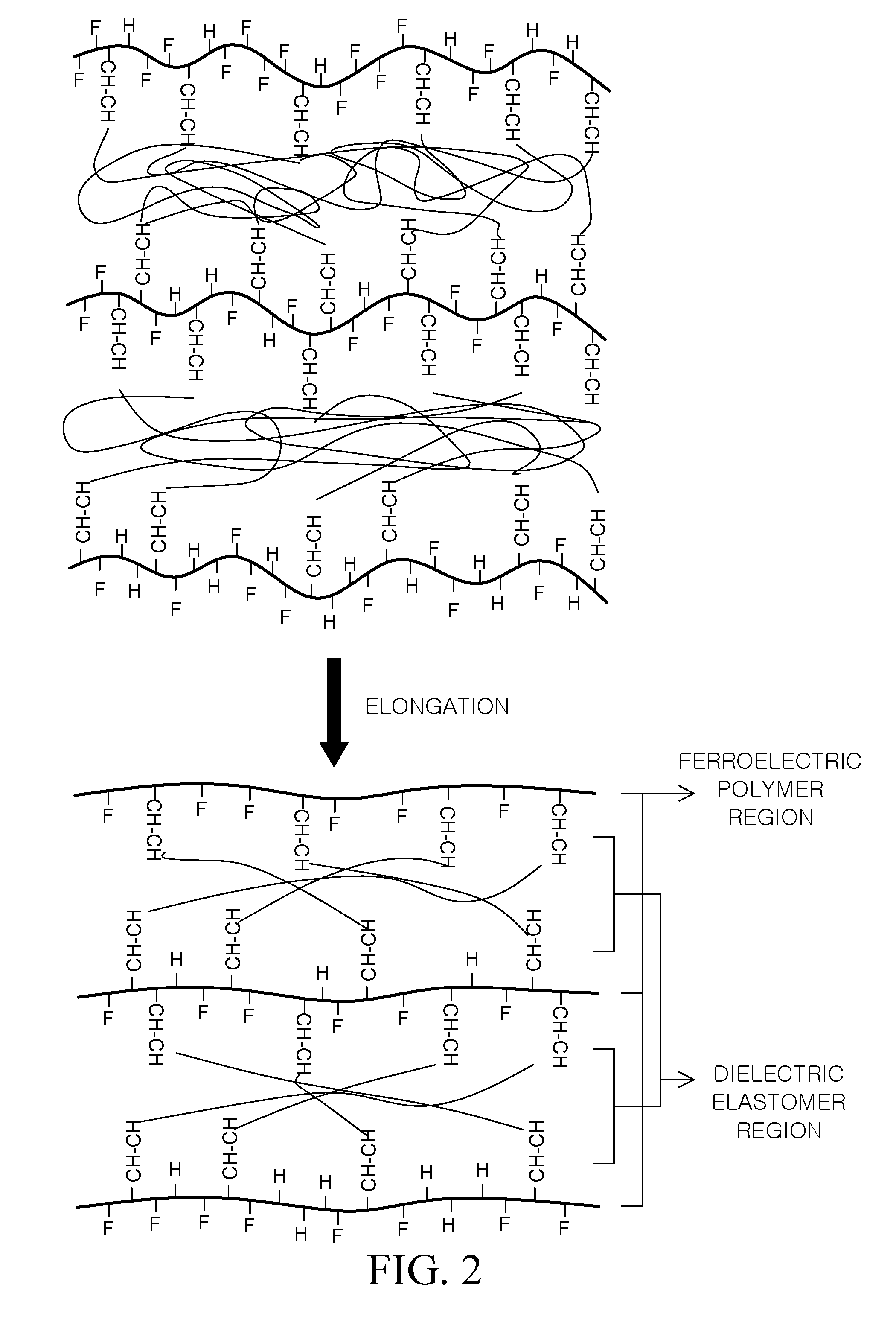

Method used

Image

Examples

production example

Production of Siloxane Polymer Having a Fluoro Group Bonded to Backbone

[0138]In 100 ml of toluene solvent, 10 g of polyhydrogenmethylsiloxane (PHMS, weight average molecular weight: 3000) as a silicon-based crosslinker was dispersed. 30 ml of HF having a concentration of 1 molal was then added thereto at 60° C. to 80° C., and the mixture was treated for 3 hours to produce polyhydrogenmethylsiloxane having fluoro (F) bonded to the backbone. Thereafter, polydimethylsiloxane (PDMS, weight average molecular weight: about 40,000) having terminals substituted with a vinyl group was mixed with the produced polyhydrogenmethylsiloxane having fluoro (F) bonded to a part of the backbone at a volume ratio of 7:3 to produce a siloxane polymer.

example 1

[0139]The siloxane polymer produced in the Production Example was coated on a glass substrate by a bar coating method and then treated for 2 hours at 60° C., to manufacture an electroactive film composed of a siloxane polymer. The siloxane polymer was not elongated.

example 2

[0140]A non-elongated electroactive film was manufactured in the same manner as in Example 1, except that the siloxane polymer was produced by mixing polydimethylsiloxane (PDMS, weight average molecular weight: about 40,000) having terminals substituted with a vinyl group and the produced polyhydrogenmethylsiloxane having fluoro (F) bonded to a part of the backbone at a volume ratio of 9:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation rate | aaaaa | aaaaa |

| elongation rate | aaaaa | aaaaa |

| elongation rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com