Gas cylinder valve

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

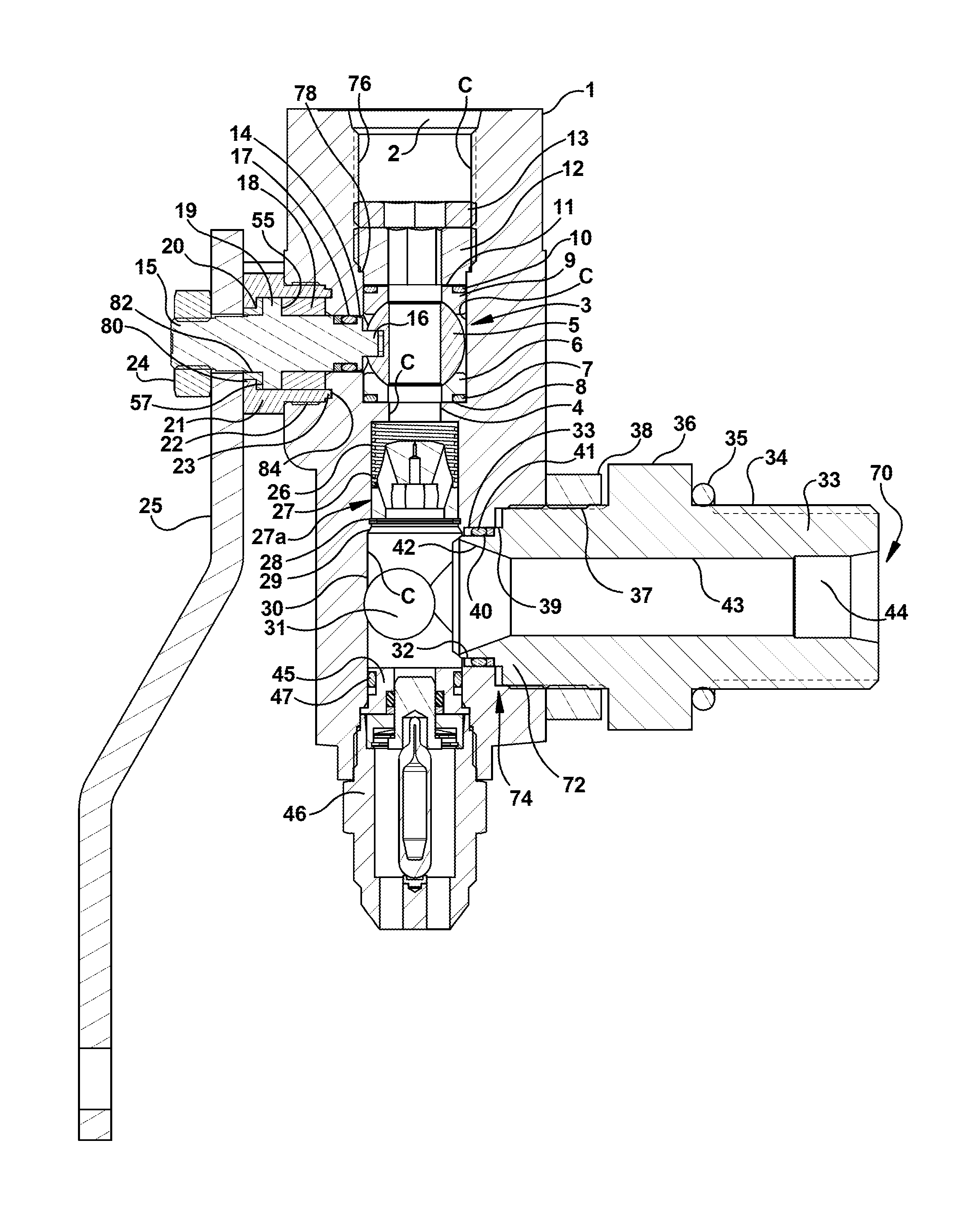

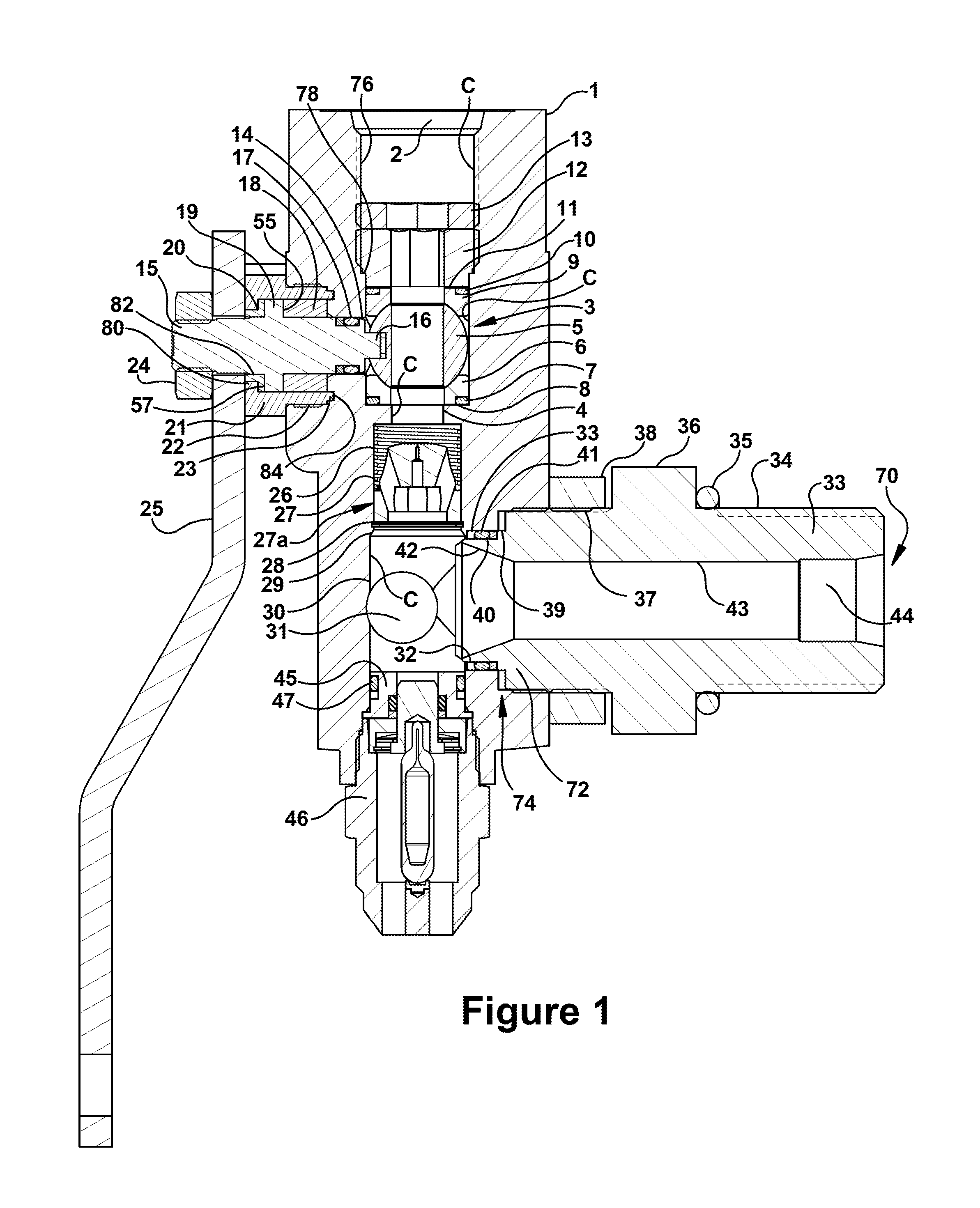

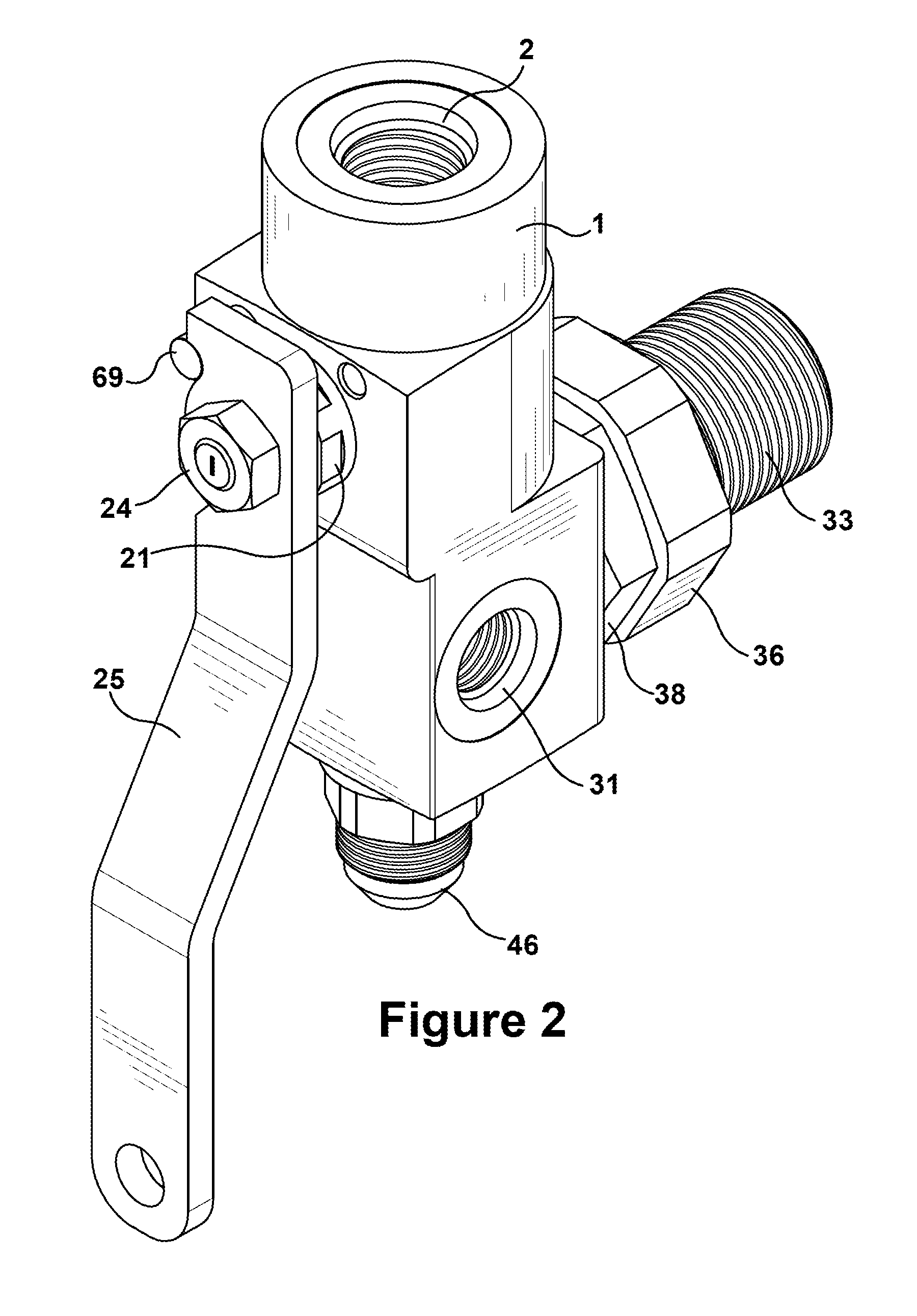

[0048]Referring to FIGS. 1 and 2, a housing or valve body 1 is in particular comprised of aluminum, for example, 6061 aluminum (or equivalent). The valve body is attached to an O-ring sealed, removable tube or threaded tube or stud 33 which mounts the valve into a mating high pressure container (e.g., a gas cylinder). The stud comprises a gas cylinder aperture 70 at its proximal end, a tube aperture 72 at its distal end for connection to a cylinder aperture 74 of the housing in order to provide fluid connection to the housing conduit C, and a tube conduit which provides fluid communication between the gas cylinder aperture and the tube aperture. In particular, the stud has an indexing feature allowing the valve body 1 to be rotated within a range (such as 370°) for optimal positioning. The stud 33 has exterior threads 34 at the proximal end portion of the stud which mate with or engage interior threads of the pressure cylinder. The same valve can be mounted to various cylinder necks...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com