Magnetic field detection sensor

a detection sensor and magnetic field technology, applied in the field of magnetic field detection sensors, can solve the problems of increasing current consumption, affecting the detection accuracy of magnetic fields, and inability to make highly sensitive measurements, so as to improve detection accuracy, reduce current consumption, and increase the detection range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024]An exemplary embodiment of the present invention will now be explained with reference to some drawings. The scope of the present invention is, however, not limited to the embodiment.

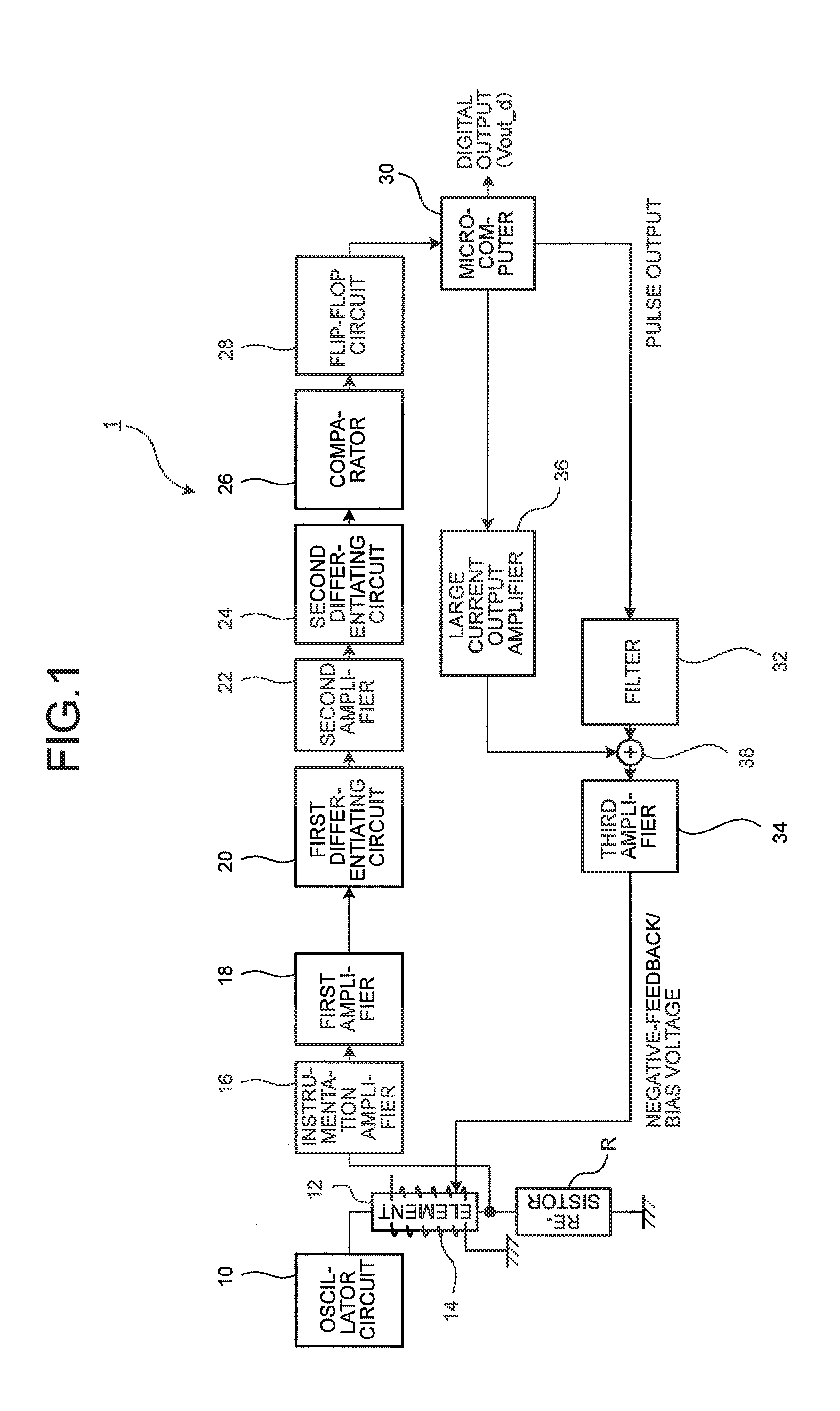

[0025]FIG. 1 is a circuit diagram schematically illustrating a magnetic field detection sensor according to an embodiment. This magnetic field detection sensor 1 illustrated in FIG. 1, which is provided as a magnetism detector, is configured to detect an external magnetic field (the direction, the azimuth, and the strength of the magnetism) based on an output of a magneto-impedance element 12 to which an AC current is applied, and is used as an element in a current sensor, an azimuth sensor, a torque sensor, or a rotation angle sensor, for example. Such a magnetic field detection sensor 1 serving as a magnetism detector includes an oscillator circuit 10, the magneto-impedance element 12, a resistor R, and a negative-feedback bias coil (bias coil) 14.

[0026]The oscillator circuit 10 is a source of an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com