Peripheral Tunnels Propeller With Alternative Balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

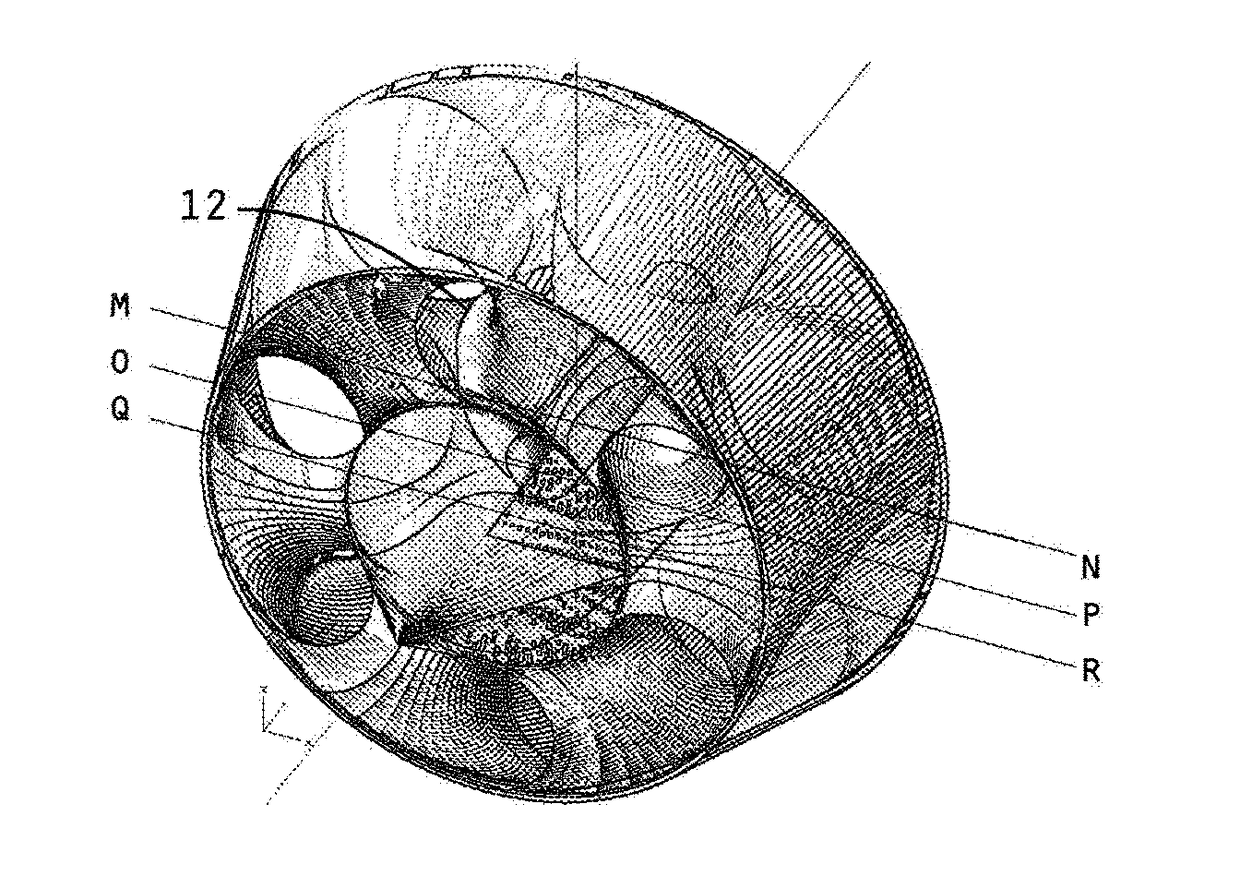

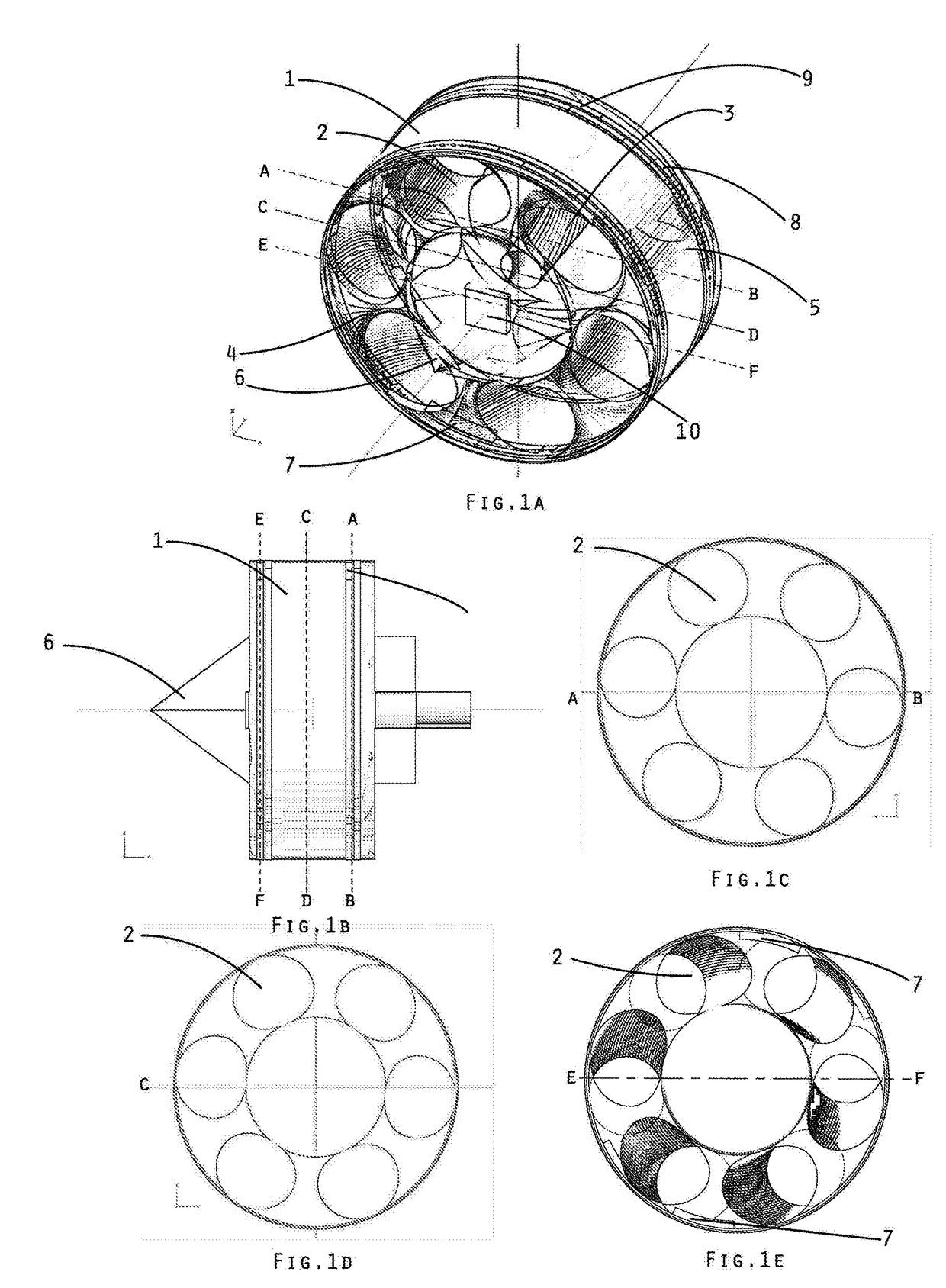

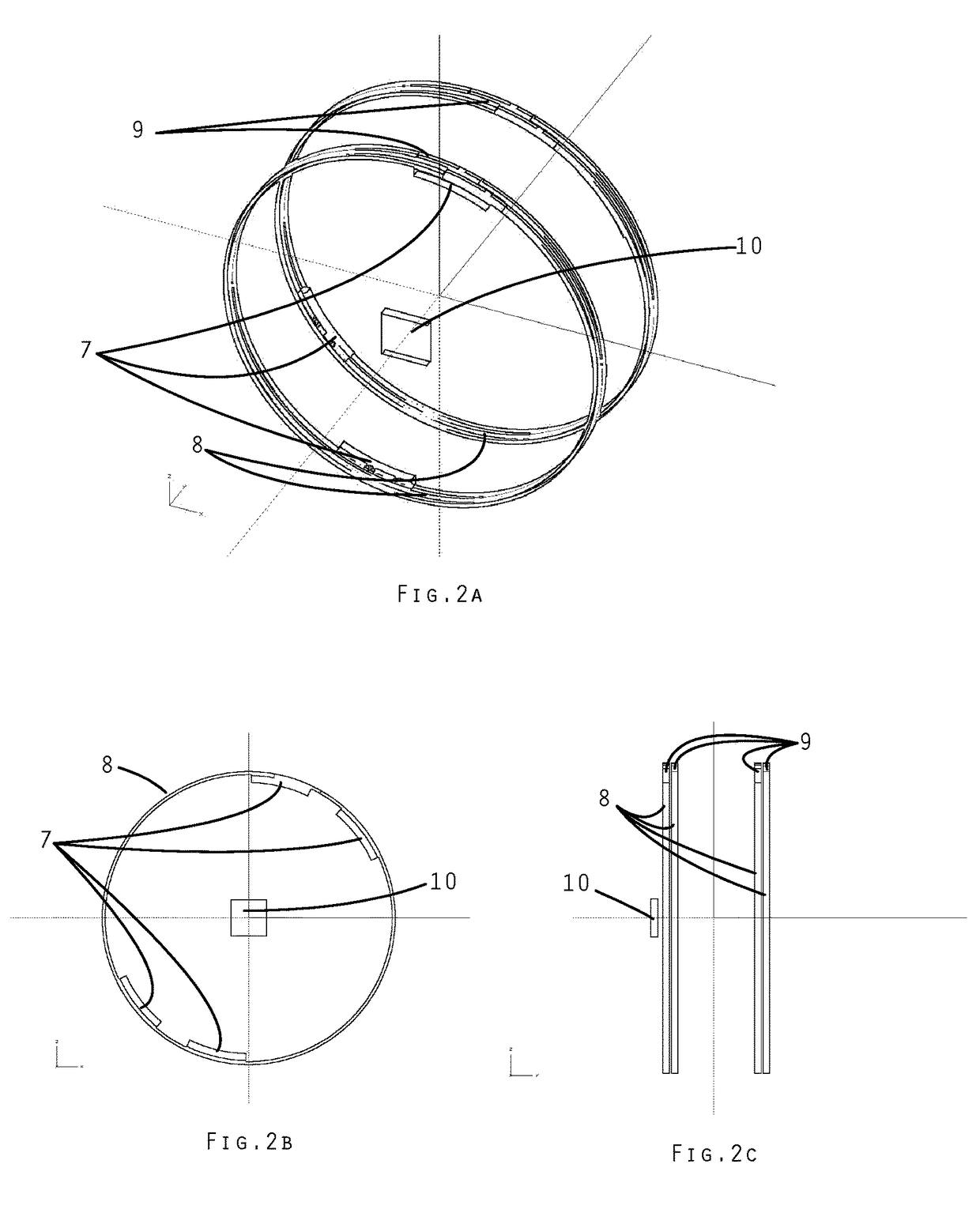

[0034]Referring now to the drawings in more detail, in FIG. 1a and FIG. 1b there is shown a cylindrical block 1 having, in its preferred embodiment, multiple peripheral holes as spiraling tunnels 2 with inlet and outlet ends. An inner shaft 3 provides rotation guide and torque to spin the cylindrical block. Fluid guide structures 4, 5 are located at each end. The cylindrical structure on its preferred embodiment ends on a conical or spherical structure 6, the Lines A-B, C-D, E-F defines a reference plane perpendicular to the rotational axis which cross-section is detailed on FIG. 1c, FIG. 1d and FIG. 1e, the illustrator also depicts the active dynamic imbalance means, comprised by mass 9, ring 8, actuator 7 and the control hub 10.

[0035]In more detail, still referring to the same embodiment, FIG. 1c depicts the tunnel's cross section 2 as Circular at the A-B line (input end), FIG. 1d depicts the cross-section of the same tunnel cross-section 2 semi-circular at the C-D line, FIG. 1e d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com