Display device and manufacturing method thereof

a technology of a display device and a manufacturing method, which is applied in the direction of instruments, non-linear optics, optics, etc., can solve the problems of reduced visibility, increased power consumption, and device including a reflective liquid crystal display element has problems of dark display, etc., and achieves high visibility, low power consumption, and high convenience.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

[0097]In this embodiment, a display device of one embodiment of the present invention will be described with reference to FIGS. 1 to 19.

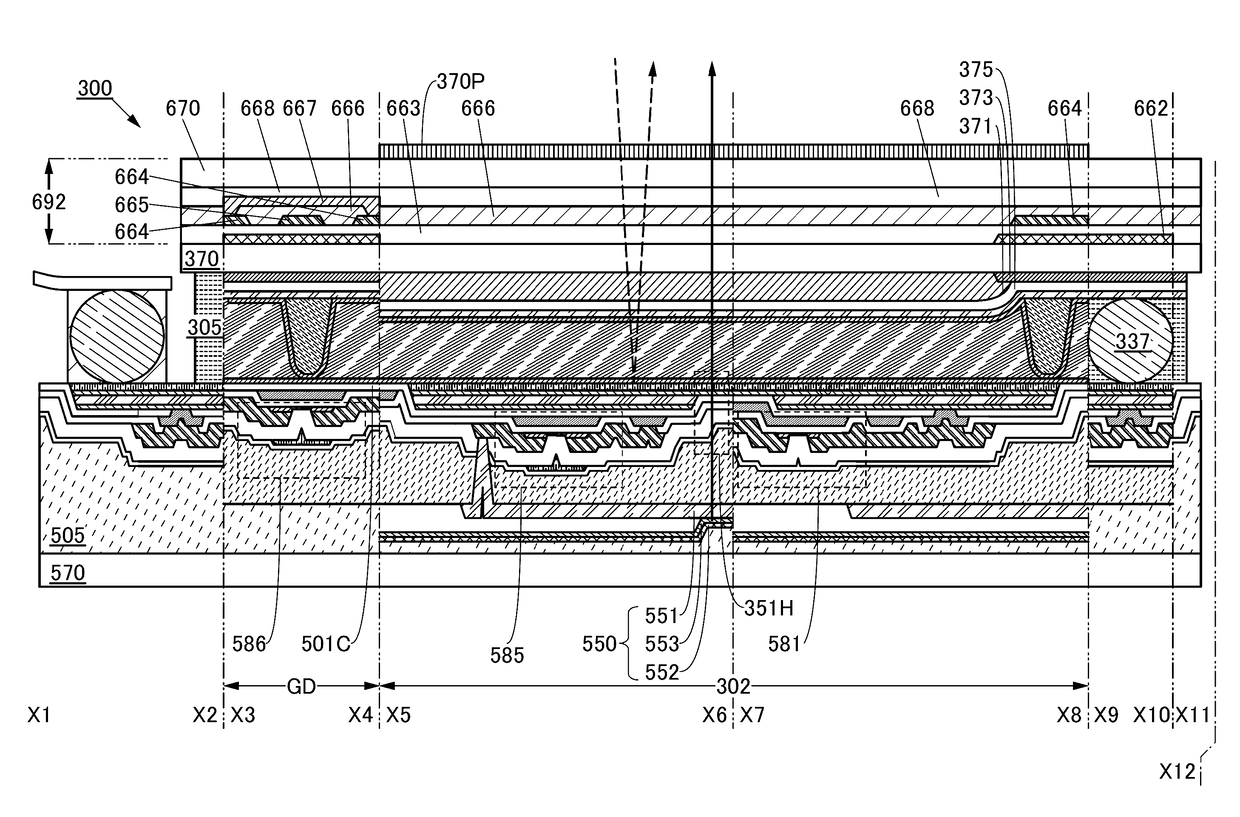

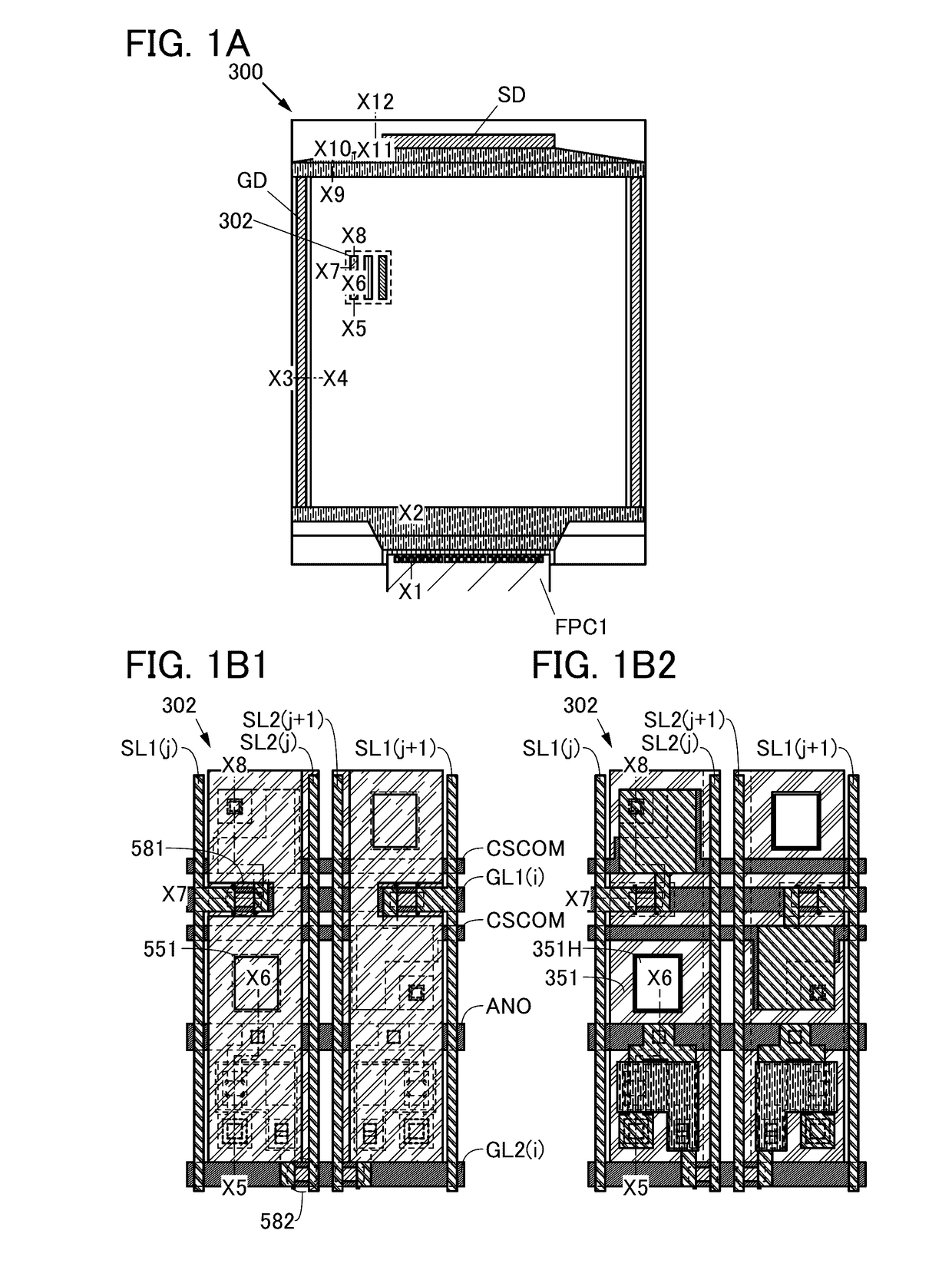

[0098]FIG. 1A is a bottom view illustrating the structure of a display device 300 of one embodiment of the present invention. FIG. 1B1 is a bottom view illustrating part of FIG. 1A. FIG. 1B2 is a bottom view omitting some components illustrated in FIG. 1B1.

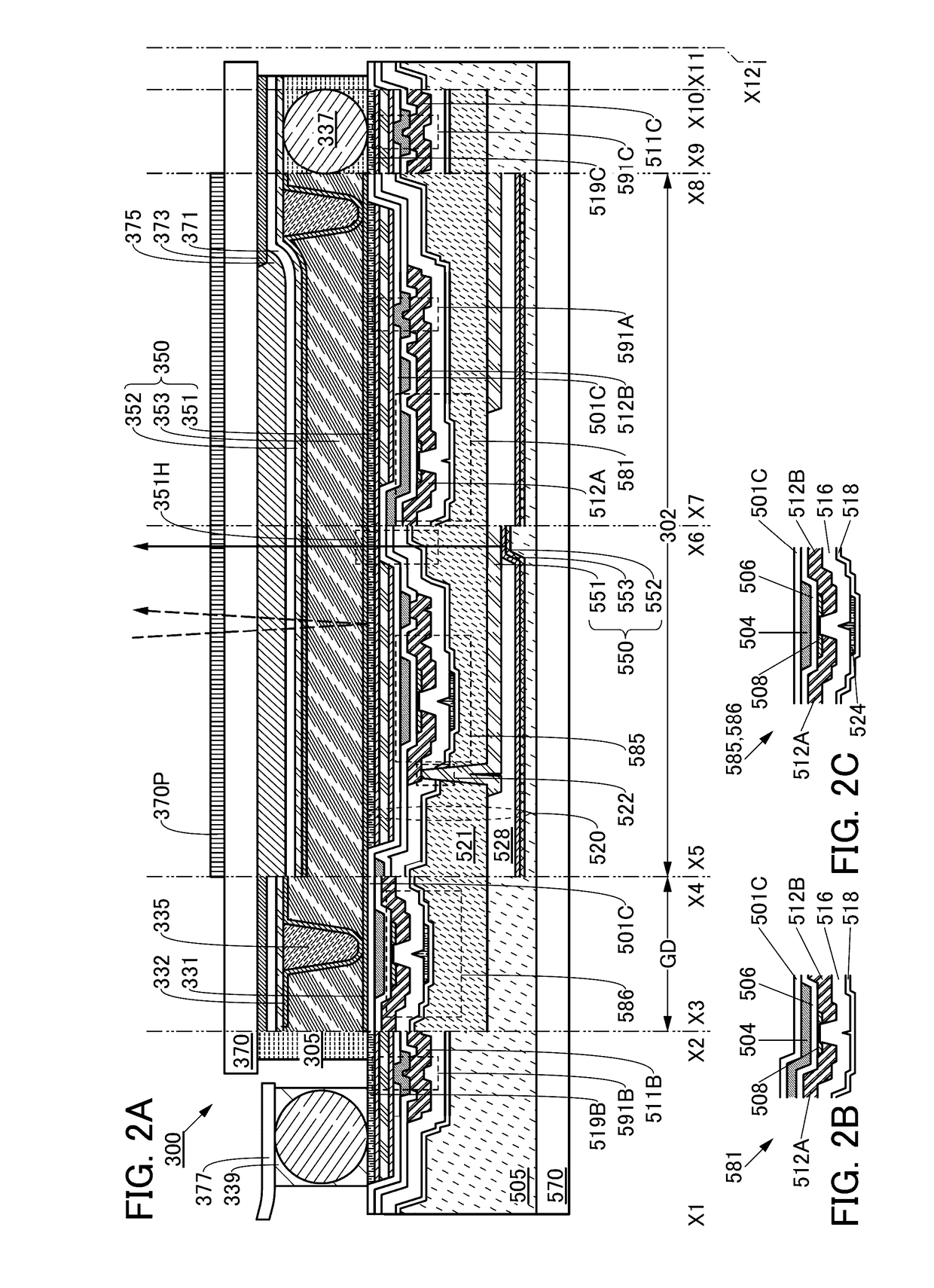

[0099]FIGS. 2A, 2B, and 2C are cross-sectional views illustrating the structure of the display device 300 of one embodiment of the present invention. FIG. 2A is a cross-sectional view taken along dashed-dotted lines X1-X2, X3-X4, X5-X6, X7-X8, X9-X10, and X11-X12 in FIG. 1A. FIG. 2B is a cross-sectional view illustrating part of the display device. FIG. 2C is a cross-sectional view illustrating other part of the display device.

[0100]FIG. 3 illustrates a circuit of a pixel 302 included in the display device 300 of one embodiment of the present invention.

[0101]As illustrated in FIG. 1A, the display ...

embodiment 2

[0447]In this embodiment, a transistor which can be used in a display device of one embodiment of the present invention is described with reference to FIGS. 20 to 34.

[0448]FIG. 20A is a top view of a transistor 200 that can be used in a display device of one embodiment of the present invention. FIG. 20B is a cross-sectional view taken along a dashed-dotted line X1-X2 in FIG. 20A. FIG. 20C is a cross-sectional view taken along a dashed-dotted line Y1-Y2 in FIG. 20A. Note that in FIG. 20A, some components of the transistor 200 (e.g., an insulating film serving as a gate insulating film) are not illustrated to avoid complexity. Furthermore, the direction of the dashed-dotted line X1-X2 may be referred to as a channel length direction, and the direction of the dashed-dotted line Y1-Y2 may be referred to as a channel width direction. As in FIG. 20A, some components are not illustrated in some cases in top views of transistors described below.

[0449]The transistor 200 includes a conductive...

embodiment 3

[0636]In this embodiment, the structure and the like of an oxide semiconductor will be described with reference to FIGS. 35 to 39.

[0637]An oxide semiconductor is classified into a single crystal oxide semiconductor and a non-single-crystal oxide semiconductor. Examples of a non-single-crystal oxide semiconductor include a c-axis-aligned crystalline oxide semiconductor (CAAC-OS), a polycrystalline oxide semiconductor, a nanocrystalline oxide semiconductor (nc-OS), an amorphous-like oxide semiconductor (a-like OS), and an amorphous oxide semiconductor.

[0638]From another perspective, an oxide semiconductor is classified into an amorphous oxide semiconductor and a crystalline oxide semiconductor. Examples of a crystalline oxide semiconductor include a single crystal oxide semiconductor, a CAAC-OS, a polycrystalline oxide semiconductor, and an nc-OS.

[0639]An amorphous structure is generally thought to be isotropic and have no non-uniform structure, to be metastable and not have fixed pos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com