Method of manufacturing and filling a package and corresponding package

a manufacturing method and packaging technology, applied in the field of packaging manufacturing, can solve the problems of high cost of adding mandrels or male moulds to a manufacturing machine, the sleeve does not give as much support to the inner tub as desired, and the finish of such a combination of a relatively large sleeve and a small tub is unsightly, so as to achieve the effect of easy production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

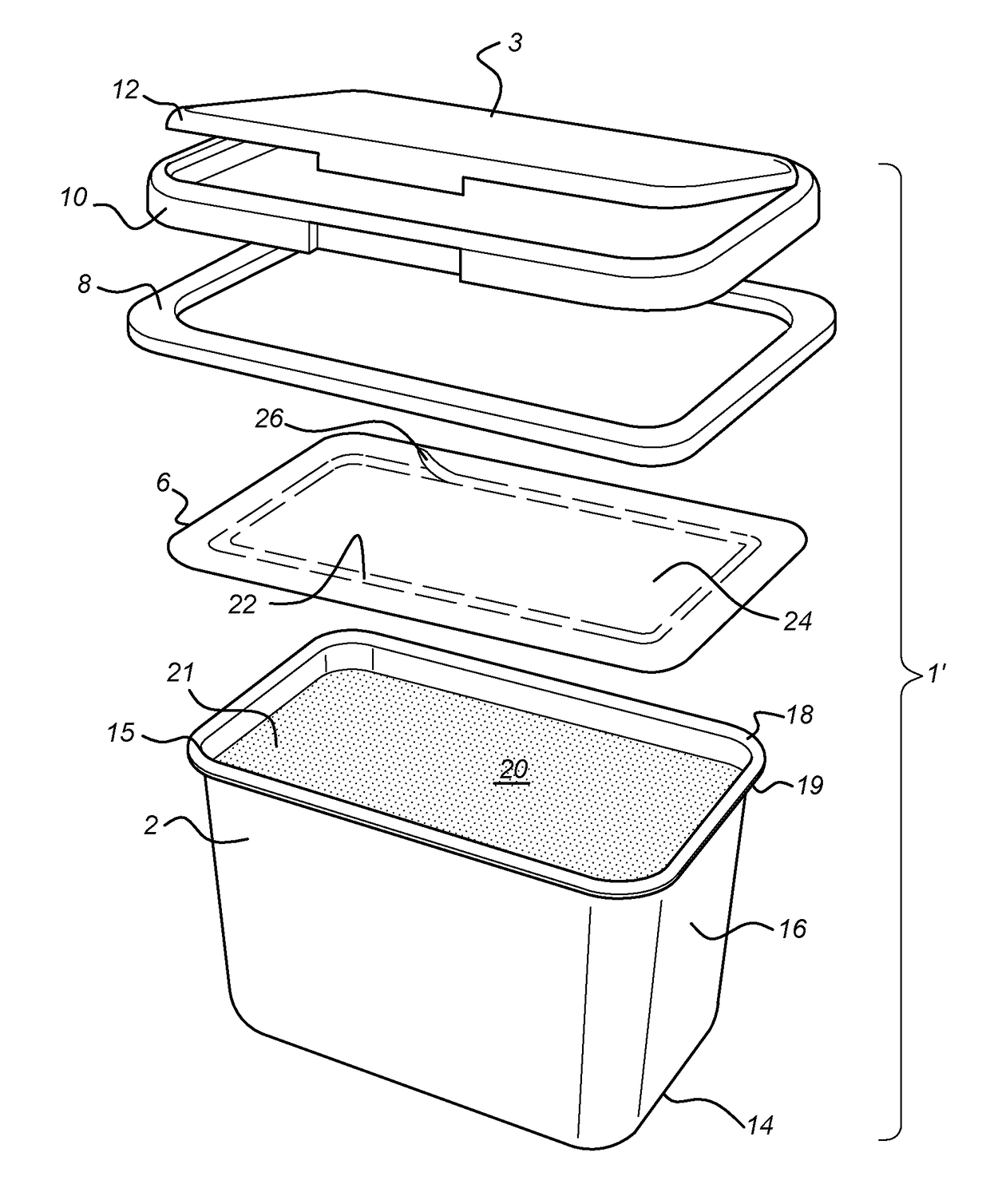

[0056]FIG. 1 shows in perspective view a package 1 manufactured according to the present invention. The package 1 is in its completed state and includes a tub 2, enclosed by a sleeve 4, and a lid assembly 3.

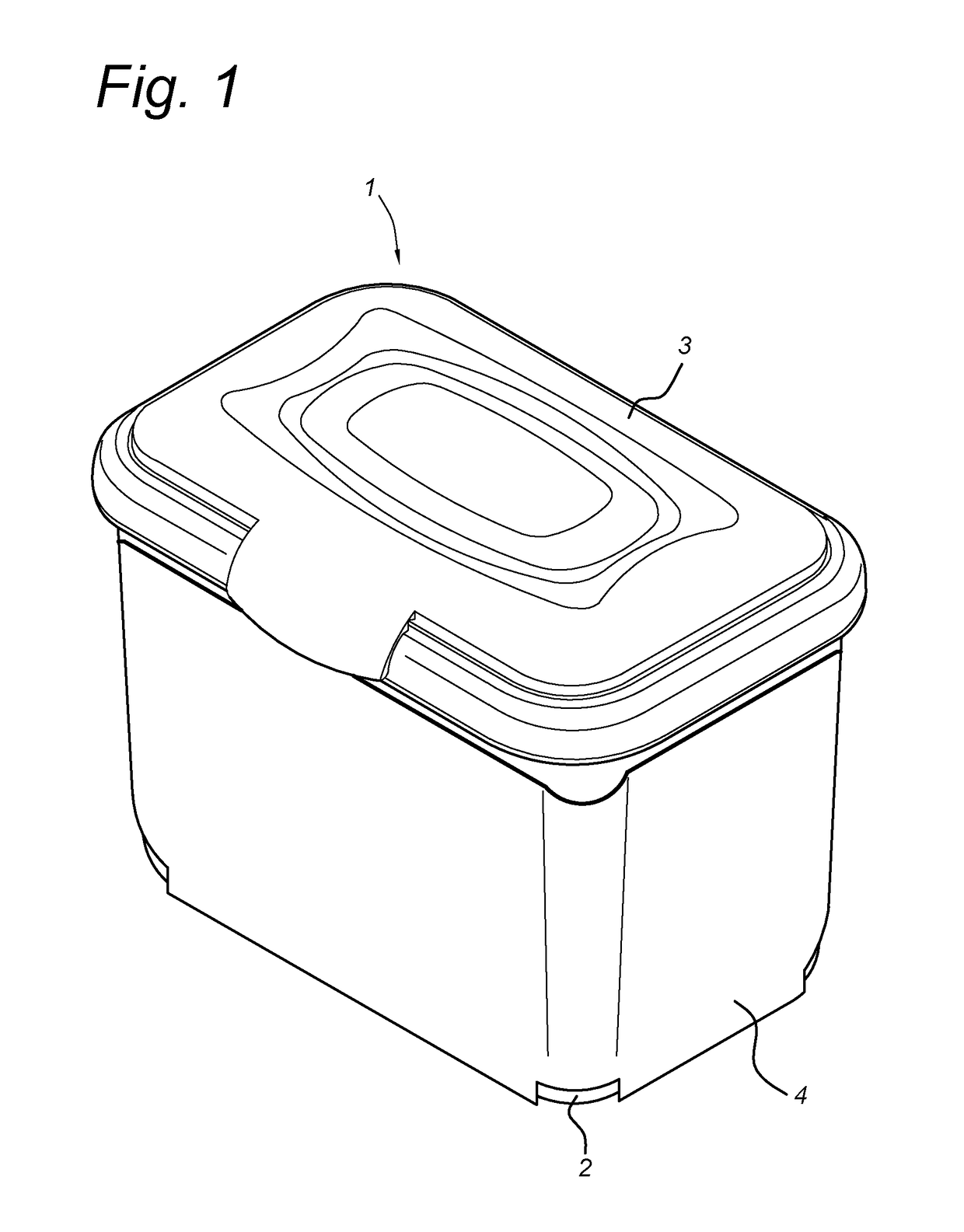

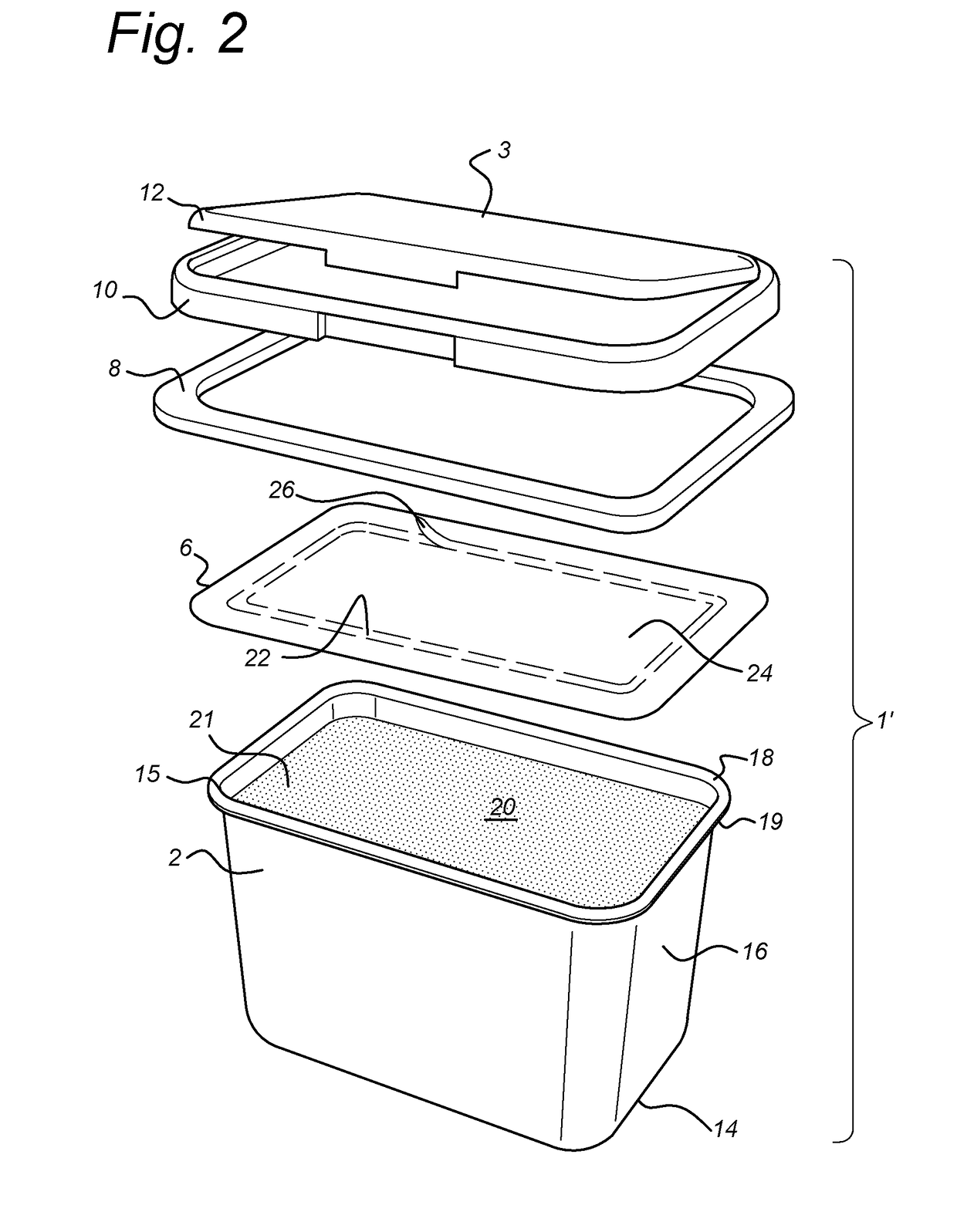

[0057]FIG. 2 shows a partially exploded view of the tub 2 and the lid assembly 3 showing further a membrane 6, a lower rim 8, an upper rim 10 and a lid 12 forming a first assembly part 1′ of the package 1. The tub 2 is thermoformed of a laminate of inner and outer relatively thin polypropylene material layers and an intermediate EVOH barrier layer. It includes a base 14 and a peripheral wall 16 defining a product containing space 20, i.e. the tub 2 is filled with a powdered nutritional product 21 before the membrane 6 is connected over the open mouth 15 of the tub. The peripheral wall 16 extends to an upper edge 18 having an outwardly directed flange 19.

[0058]Lower rim 8 is formed as a flat annular ring of a similar dimension to the outwardly directed flange 19. The lower rim 8 i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| RH | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com