Package system and method for inhibiting moisture entry

a technology of moisture entry and packaging system, applied in the field of packaging system, can solve the problems of cake tendency, i.e., joining together, caking of solids, etc., and achieve the effect of low moisture transmission ra

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

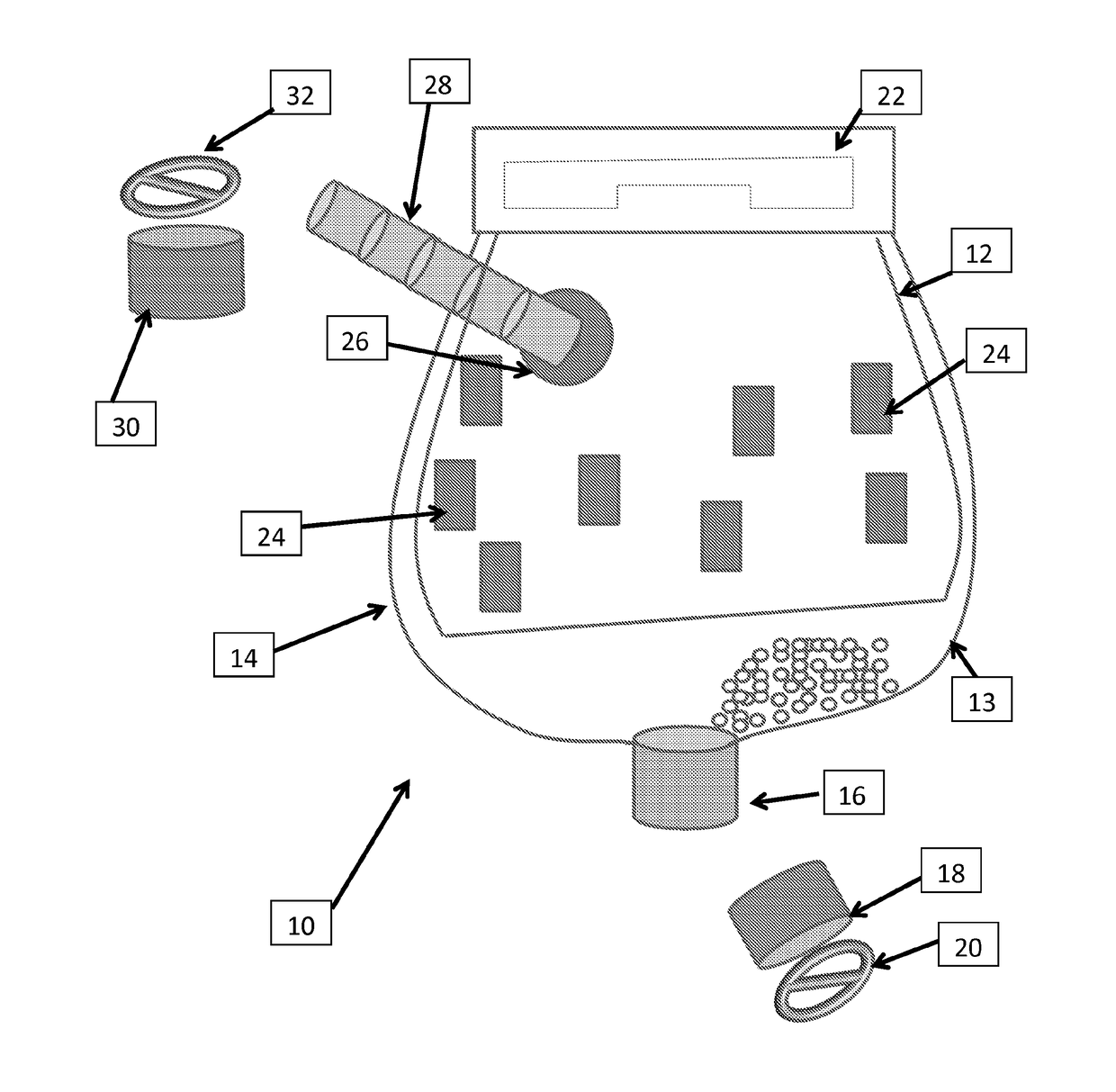

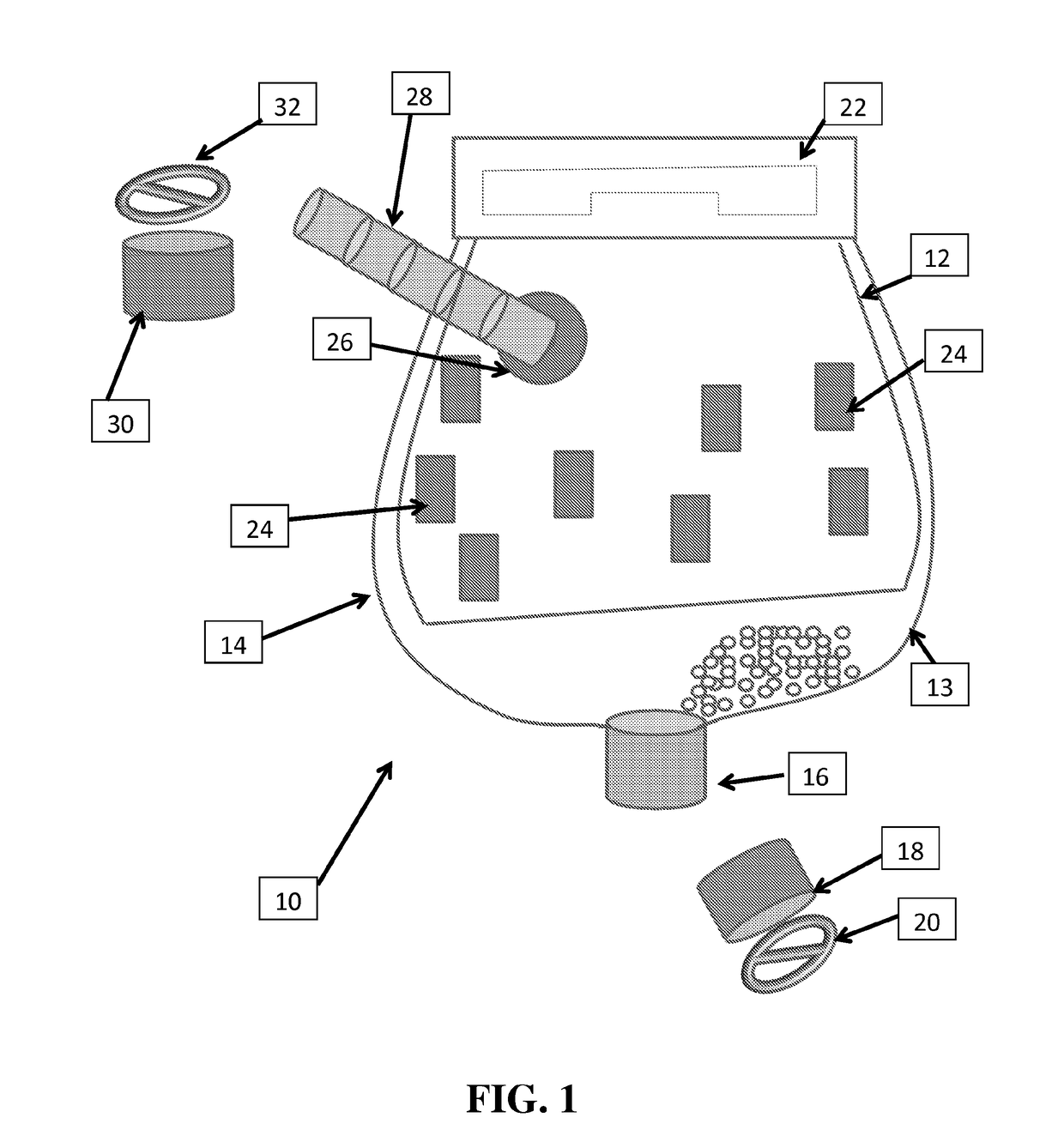

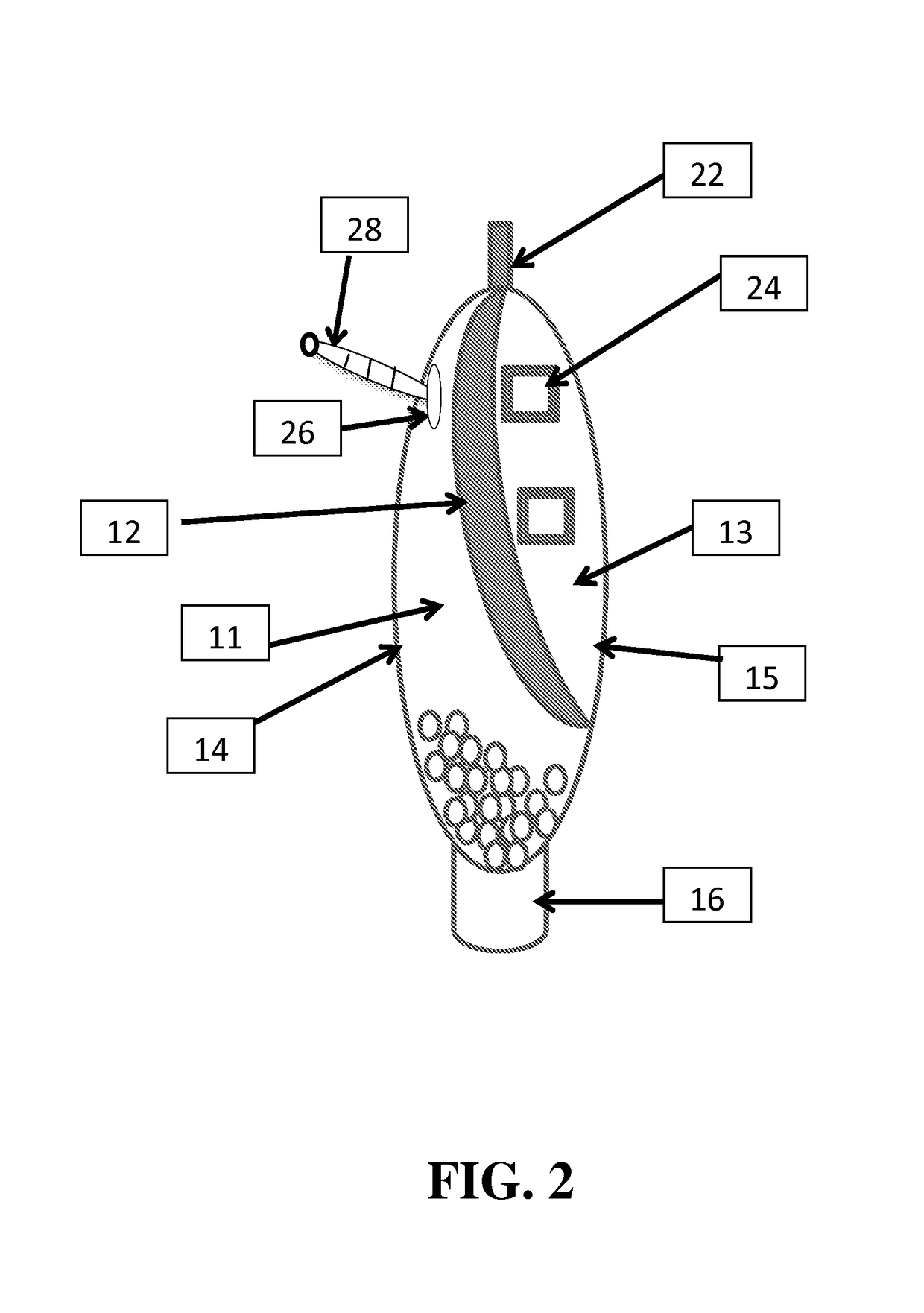

[0090]A model test bag was produced by heat sealing a multi-layer bag, which included an interior layer made of Tyvek® that provides a vapor transmission wall disposed between two outer layers made of substantially gas and moisture impermeable HDPE. The top edges of the three layers were aligned in registration and the interior Tyvek® layer extended to a point intermediate the first and second ends of the two outer layers. The bottom and two side perimetrical edges of the outer layers of HDPE were sealed together to form a first compartment and the perimetrical edges on the bottom and two sides of the Tyvek® layer were sealed to the first outer HDPE layer to form a second compartment. One kg of the test salt was placed in the first compartment from the top end of the bag on one side of the Tyvek® layer and the desiccant material was placed on the other side (five ⅙ clay type desiccants from Desicare) of the Tyvek® layer in the second compartment. The perimetrical edges of the three ...

example 2

[0091]A lab study was carried out to demonstrate the ability of the package system to maintain materials in the free-flowing state. In addition, tests were performed to compare the package system to a prior art single use bag. The new package system bag was filled with 11.3 kg of free-flowing sodium chloride and the end cap, clamp and clip were placed on the bag. Another standard single use bag without the compartment for the desiccant (i.e., the Flowmor™ technology) was filled with same amount of free-flowing sodium chloride and sealed in the same manner. Both bags were placed side by side in a stability chamber at 40° C. and 75% RH. Both bags were tested after 32 days; the sodium chloride in the package system (see the photograph in FIG. 12) was free flowing and cake free. The material in the prior art bag (see the photograph in FIG. 13) was caked and not free-flowing.

example 3

[0092]Studies were carried out under high moisture conditions (40° C., 90% RH) on the bags, to study moisture infusion rates into the wall of the bag. A bag was placed in the stability chamber with a weighed eight units of desiccant (approximately 8 ounces); the cap and clip were placed on the bag and sealed. The desiccant, after 96 hours, gained 6.5 grams of water, which showed that the desiccant would be used up in 30 days at this water vapor transmission rate. The bag was then placed in a Mylar® bag (or any suitable bag with low moisture vapor transmission rate) and heat sealed. The vapor transmission rate was significantly increased and the test results showed an expected shelf life of over 400 days.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| densities | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com