Lead-Free Brass Alloy

a brass alloy, lead-free technology, applied in the field of brass compositions, can solve the problems of affecting the phase of copper lead alloys, toxic substances, and expensive control procedures in the production of alloys, and achieve the effects of eliminating or reducing the amount of retooling, excellent dezincification resistance, and excellent machinability and conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

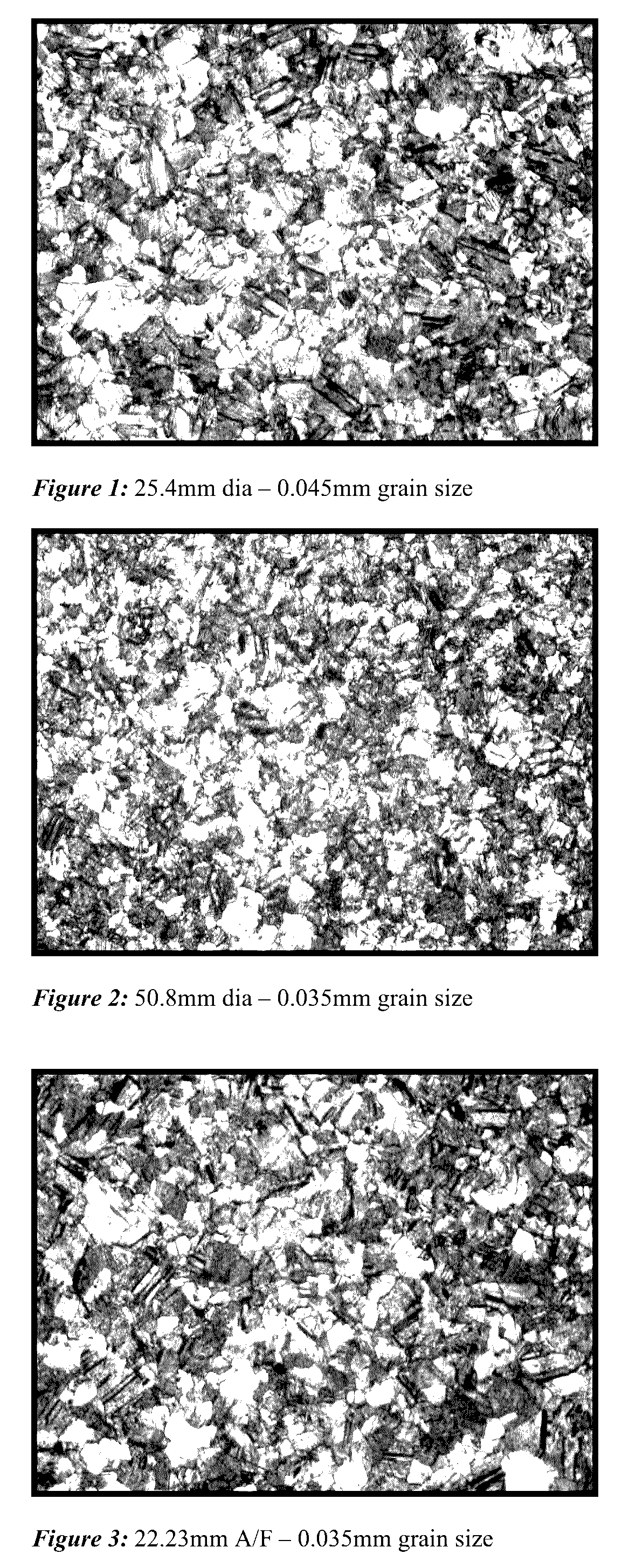

[0023]A series of brass alloys were prepared where the added lead (typically about 2%) was replaced with approximately 0.5% tellurium. The composition of each alloy is shown in Table 1.

TABLE 1SampleCuPbZnTePSnABalance5.100.50.011—BBalance0.008.820.57.001—C83.030.06Balance.0520.050.11D59.410.02Balance0.170.05—

[0024]The billets were then changed into an extrusion press at a temperature ranging from about 780° C. to about 860° C. The billets were then hot extruded through a variety of dies and at different pressures to produce numerous sizes. Each shot was lubricated prior to extrusion and the extrusion dies were preheated. The results are shown in Table 2.

TABLE 2SampleFinal Draw SizeShot TempPressureLengthA131.75mm808° C.234 MPa12mA275.40mm822° C.268 MPa18.5mA319.05mm803° C.305 MPa34mB131.75mm794° C.267 MPa12mB225.40mm800° C.289 MPa18.5mB319.05mm806° C.304 MPa34mB412.70mm870° C.265 MPa67mC1a25.40mm830° C.298 MPa18.4mC1b25.40mm867° C.280 MPa18.4mC2a50.80mm750° C.230 MPa21.5mC3a22.23mm8...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com