Highly emulsifiable albumen hydrolysate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

preparation example 1

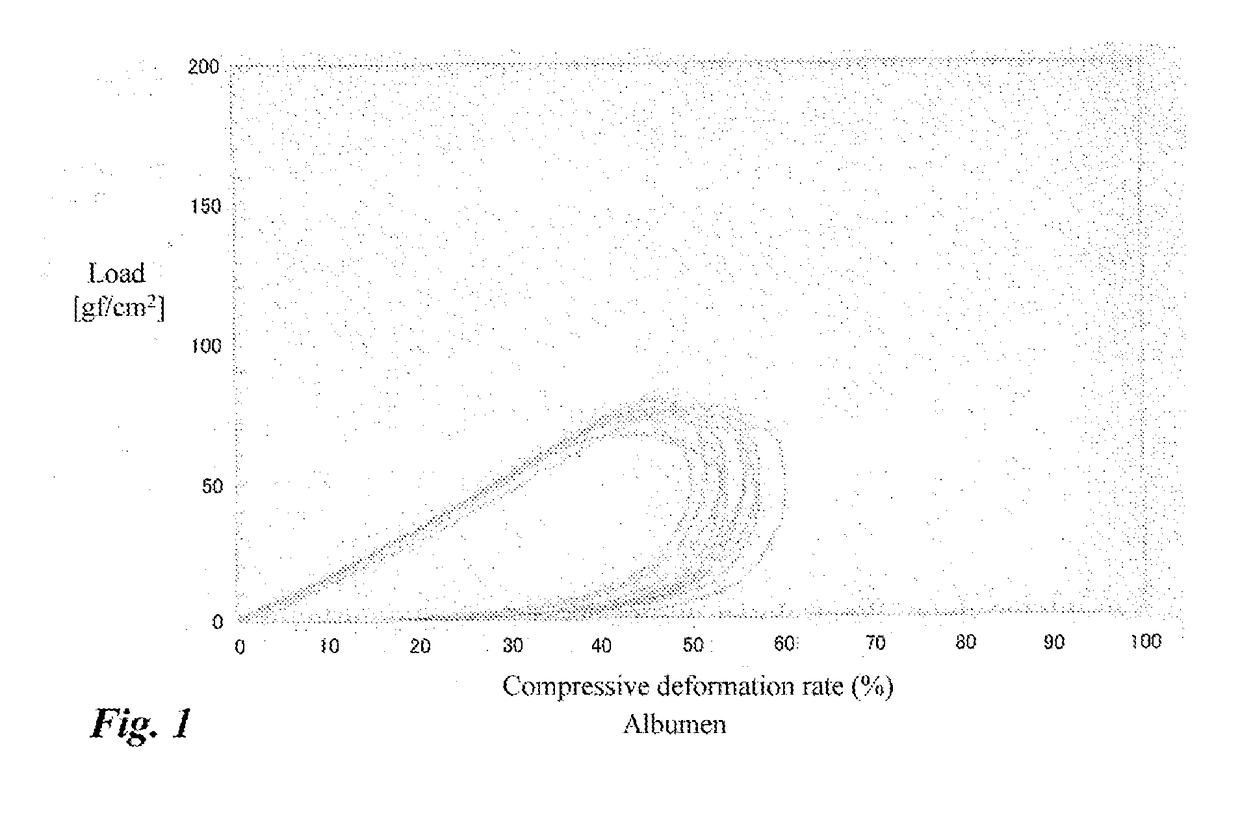

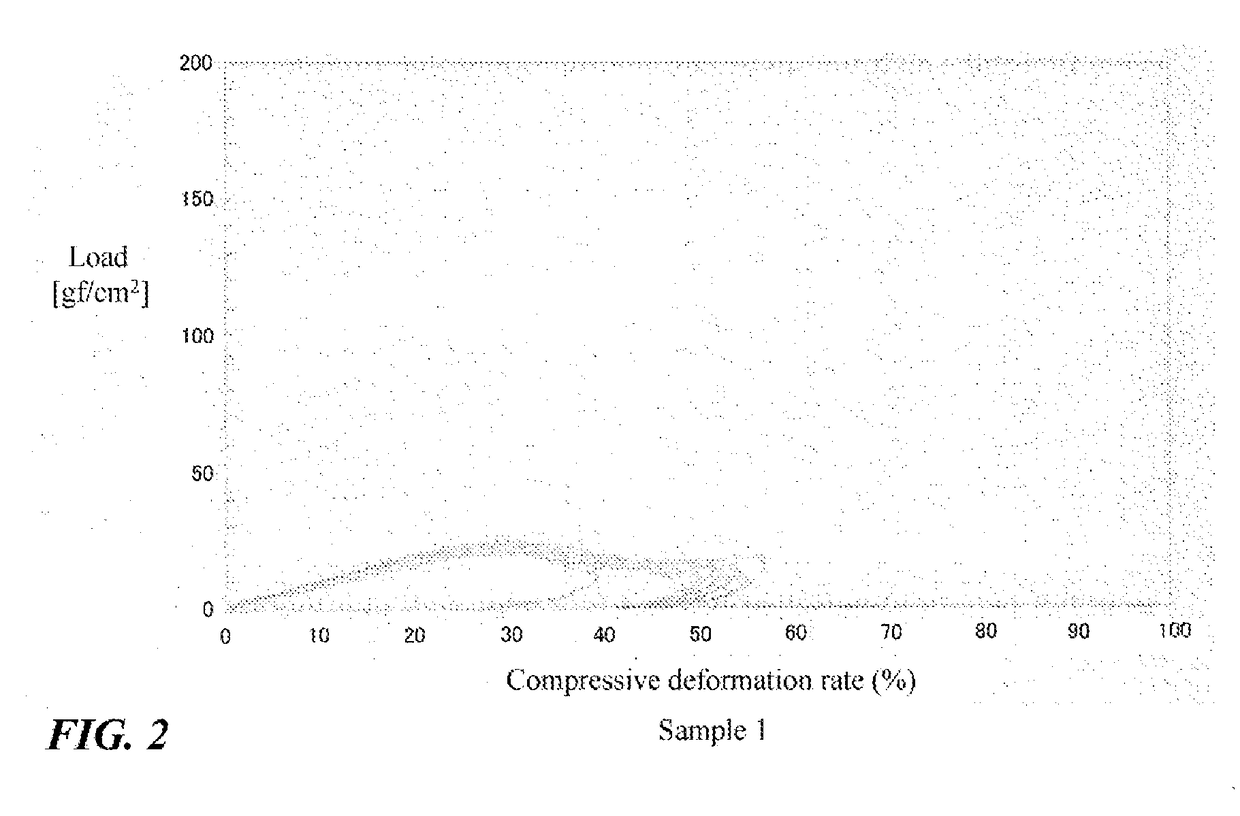

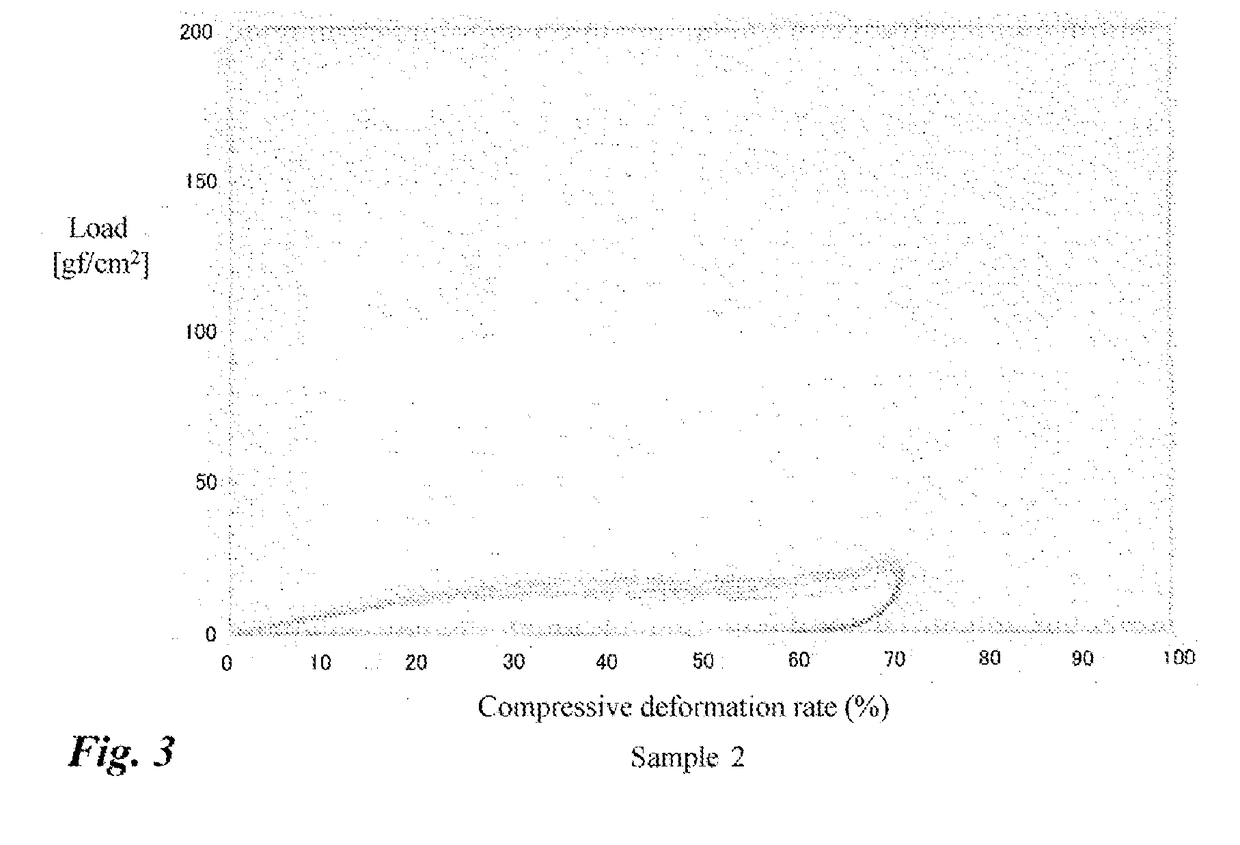

Preparation of Albumen Hydrolysate (Study on Hydrolysis Degree)

[0094]Products (500 g each) prepared by adding a 10% citric acid solution (24 ml) to 3 L of an albumen liquid (pH 9.0) and adjusting the pH of the mixture to pH 7.5 were warmed to 55° C., and a heat resistant proteolytic enzyme (Thermoase PC10F: 90,000 units / g, Amano Enzyme Inc.) was added thereto in an amount of 0.1%, 0.2%, 0.4% and 0.8%, respectively. The resultant mixtures were enzymatically decomposed while being stirred at 55° C. for 10 minutes. Then, the albumen liquids were subjected to temperature increase to 65° C., and enzymatically decomposed while being stirred for further 30 minutes. Thereafter, the albumen liquid was immediately subjected to temperature increase to 90° C., and held for 10 minutes for enzyme deactivation. The albumen hydrolysates after the enzyme deactivation were stirred to be homogenized, thereby preparing albumen hydrolysate samples 1 to 4. Incidentally, an albumen liquid was similarly ma...

preparation example 2

Mass Preparation 1 of Albumen Hydrolysate

[0102]One hundred (100) Kg of an albumen liquid (pH 7.8) was warmed by a warm water circulation jacket tank (200-L-volume), and 200 g of Thermoase PC10 was added thereto and dissolved therein at 55° C. The liquid was stirred for 10 minutes. Then, the liquid temperature was increased to 65±2° C., and the liquid was stirred for 30 minutes. Thereafter, the liquid temperature was held at 95±2° C. for 5 minutes, and enzyme deactivation was carried out also for heat sterilization. Then, the protease-treated hydrolyzed albumen was stirred to be homogenized with a homomixer, thereby preparing 97.2 Kg of an albumen hydrolysate (Sample 6).

preparation example 3

Mass Preparation 2 of Albumen Hydrolysate

[0103]Using a warm water circulation jacket tank (200-L-volume) as a balance tank, 200 Kg of an albumen liquid (pH 8.5) was circulated to a shell & tube type heat exchanger, STD model (Iwai Kikai Kogyo Co., Ltd.) at a flow rate of 150 Kg / h, and, when the temperature of the liquid within the balance tank reached 55° C., 200 g of Thermoase PC10 was added and dissolved. The temperature was retained at 55±2° C., and the liquid was circulated for 10 minutes. Then, the liquid temperature was rapidly increased to 65° C., and retained at 65±2° C., and the liquid was circulated for 30 minutes. Finally, the liquid temperature was retained at 95±2° C. for 5 minutes, and enzyme deactivation was carried out also for heat sterilization. Then, the liquid was rapidly cooled, thereby preparing193 Kg of an albumen hydrolysate (Sample 7).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com