Control system for vehicle

a control system and vehicle technology, applied in the direction of electric control, machines/engines, transportation and packaging, etc., can solve the problems of not being able to appropriately inhibit abnormal combustion in a period, etc., to achieve the effect of reducing the driving experien

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

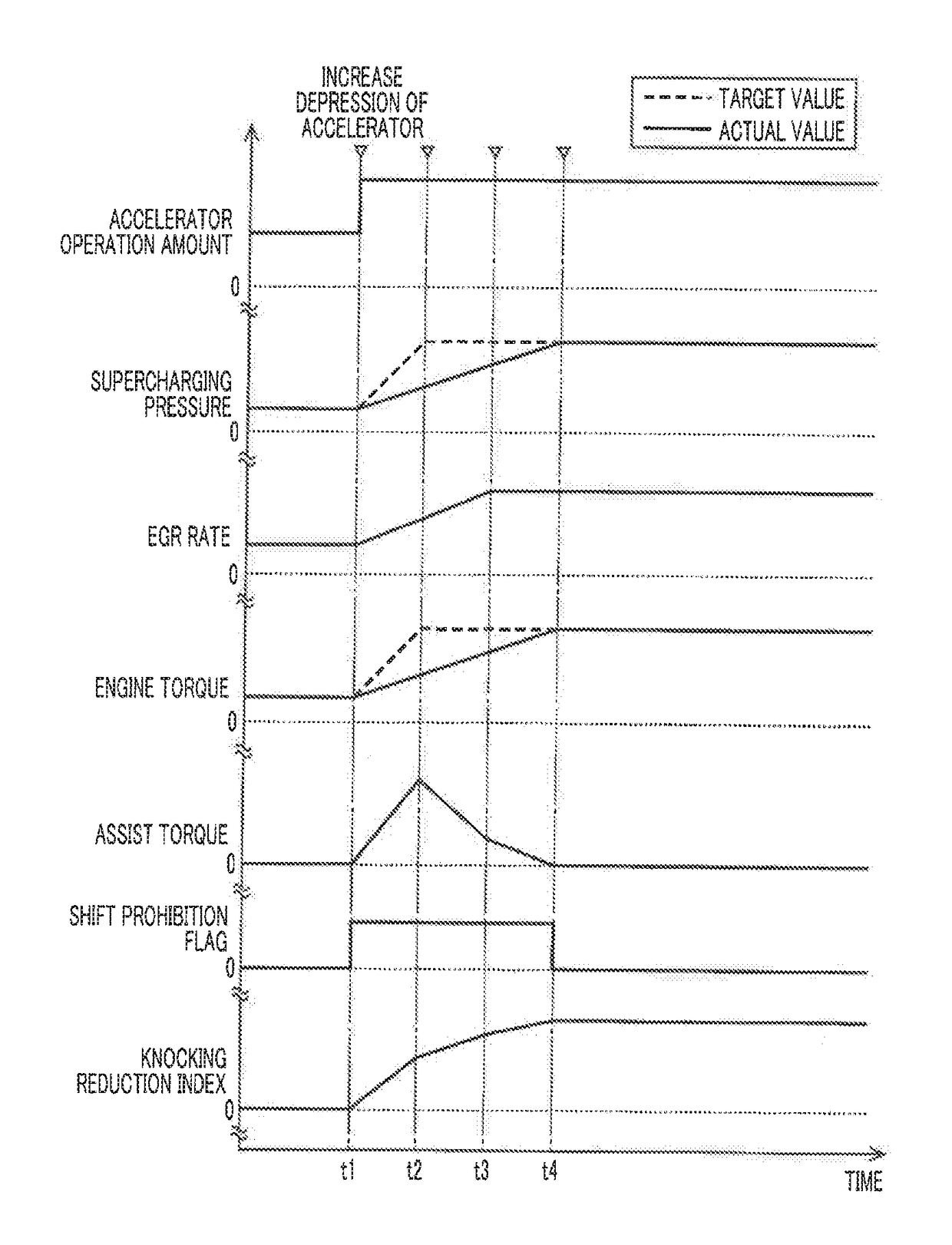

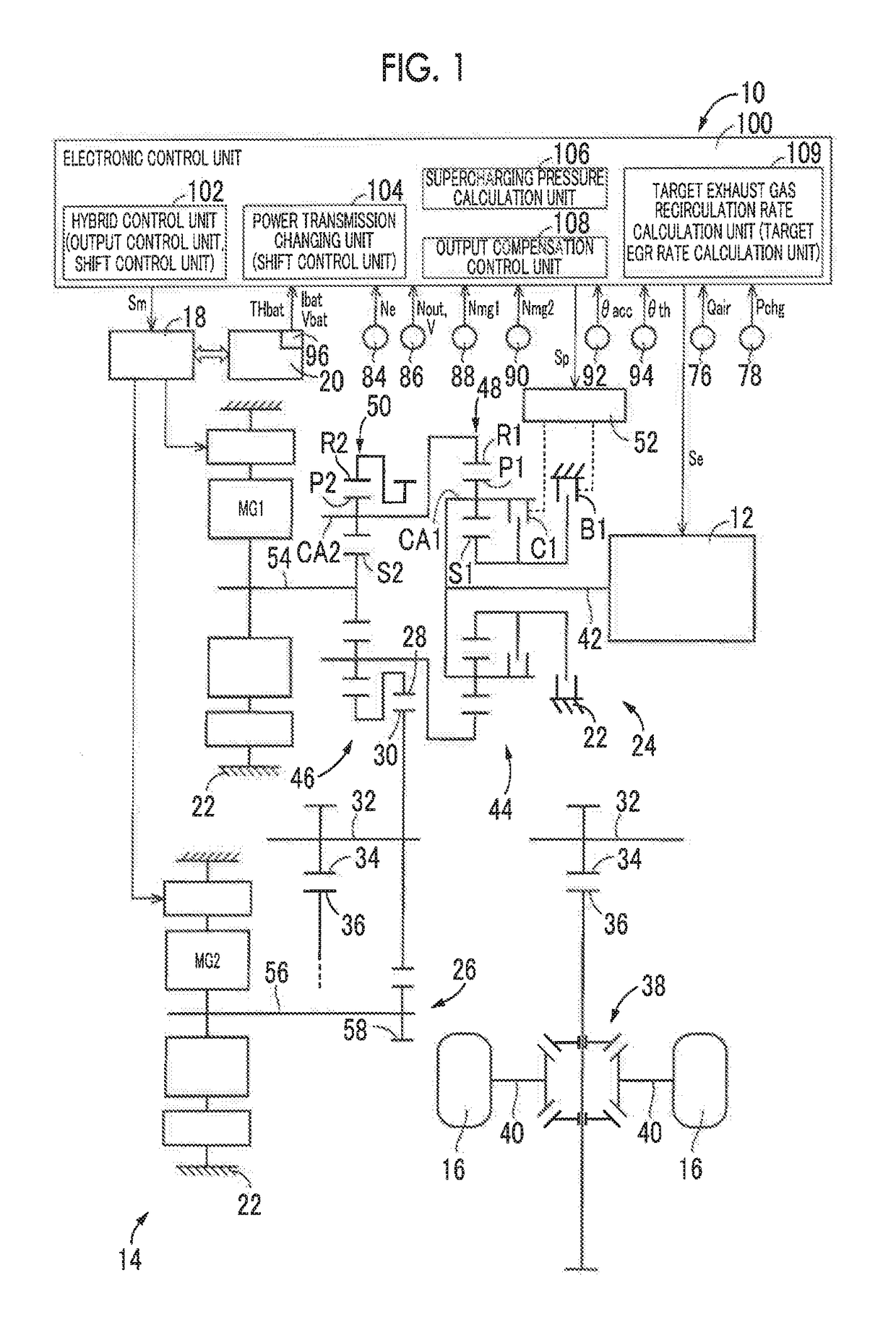

[0036]Hereinafter, embodiments of the present disclosure will be described in detail with reference to the accompanying drawings.

[0037]FIG. 1 is a view that illustrates the schematic configuration of parts regarding traveling of a vehicle 10 to which the present disclosure is applied and is a view that illustrates a relevant portion of control system for controlling the parts. As shown in FIG. 1, the vehicle 10 is a hybrid vehicle including an HCCI engine 12, a first electric rotary machine MG1, a second electric rotary machine MG2, a power transmission system 14 and drive wheels 16. The HCCI engine 12, the first electric rotary machine MG1 and the second electric rotary machine MG2 can serve as driving force sources for propelling the vehicle 10.

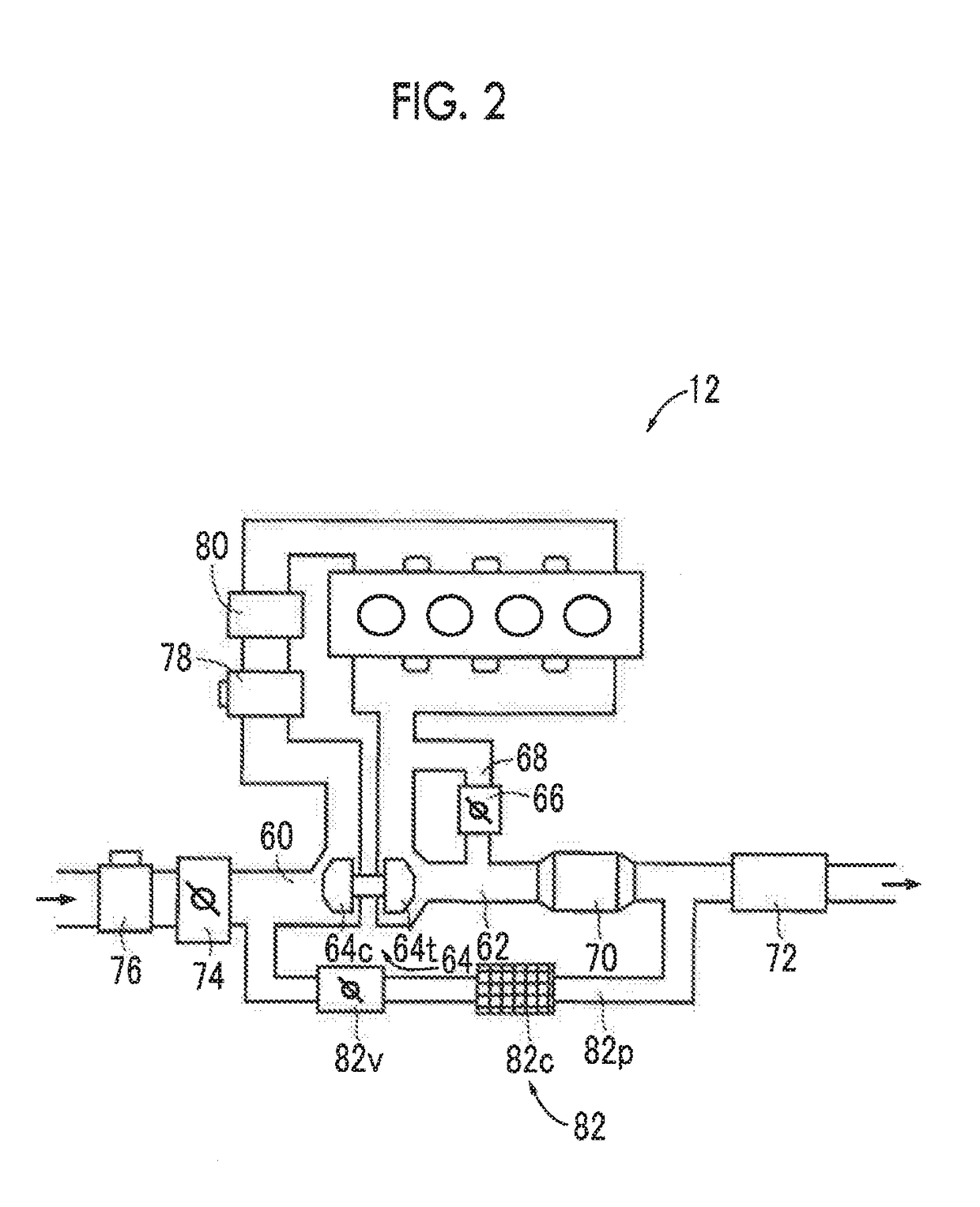

[0038]The HCCI engine 12 is an internal combustion engine (engine) that is able to perform homogeneous charge compression ignition (HCCI) operation for causing a lean premixture to perform self-ignition combustion. Since the HCCI engine 12 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com