System, a tangent probe card and a probe head assembly for testing semiconductor wafter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

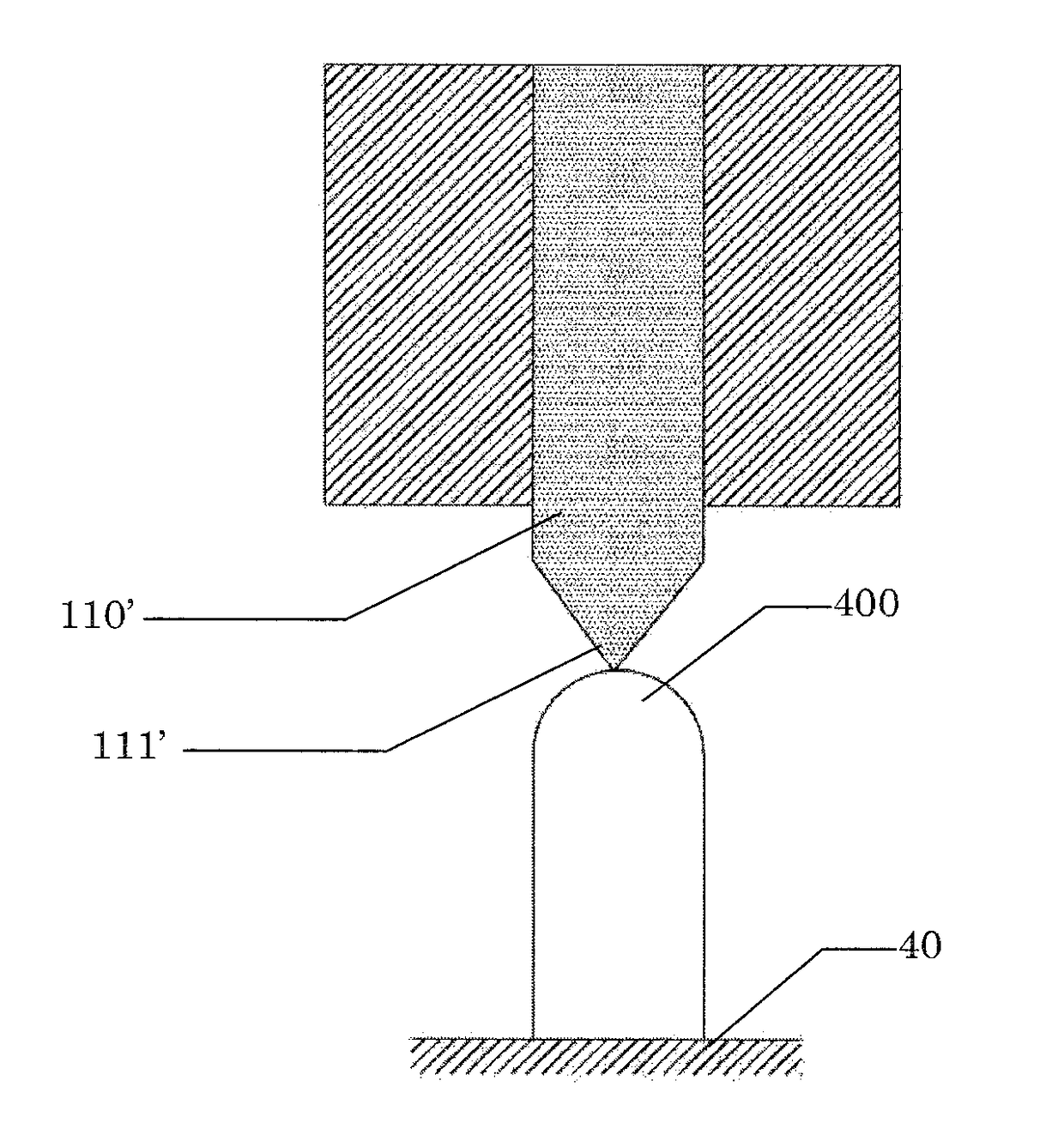

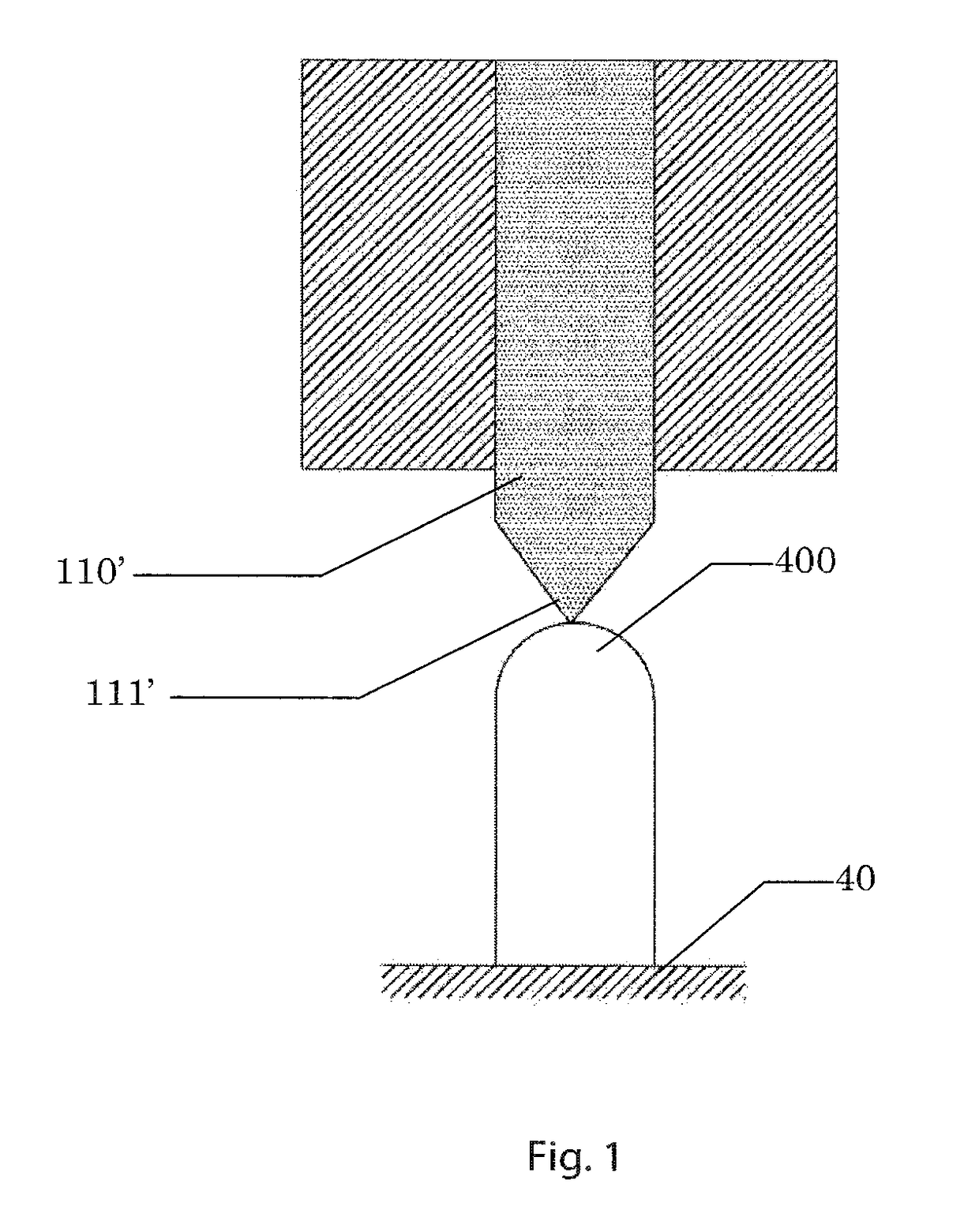

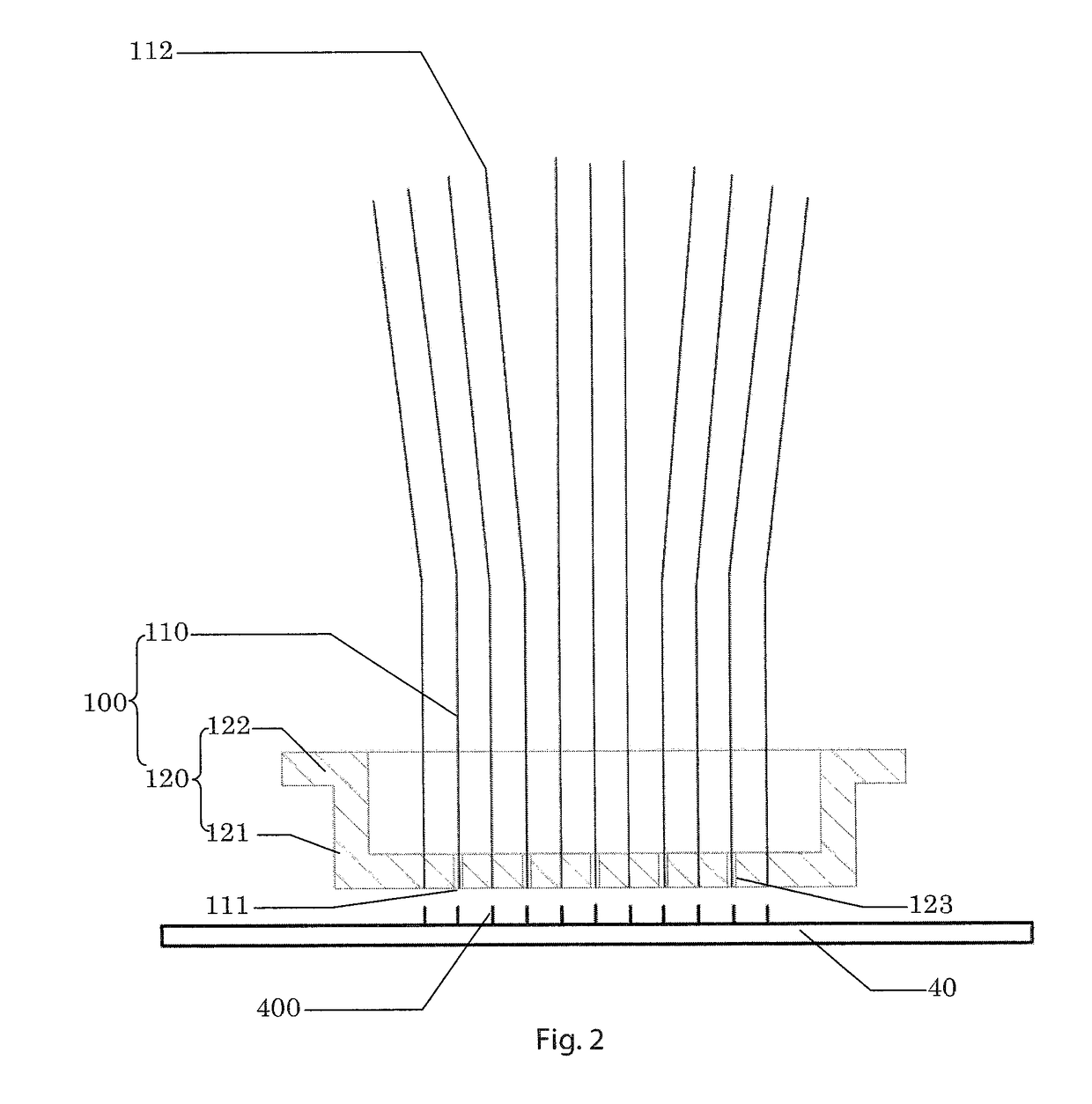

[0071]FIG. 5 is a perspective exploded view illustrating the first embodiment of the tangent probe card according to the utility model, where the plurality of probes are omitted for the sake of brevity. FIG. 6 is a bottom view of the tangent probe card according to the first embodiment. FIG. 7 is a cross-sectional view taken along the line A-A in FIG. 6. FIG. 8 is a top view of the tangent probe card according to the first embodiment, wherein the mounting hole of the upper holding block used to mount the spring is illustrated in a perspective view to show the location of the spring on the upper holding block. FIG. 9 is a cross-sectional view taken along the line B-B in FIG. 8, wherein “+” is utilized to denote the location of the spring behind the elastic ring since the spring is blocked by the elastic ring. Furthermore, the through-holes of the probe holding portion are not presented for the sake of clarity. FIG. 10 is a cross-sectional view illustrating wafer testing via the tange...

second embodiment

[0078]FIG. 11 is a perspective exploded view of the second embodiment of the tangent probe card according to the utility model, where the plurality of probes are omitted for the sake of brevity. FIG. 12 is a top view of the tangent probe card according to the second embodiment. FIG. 13 is a cross-sectional view taken along the line B-B in FIG. 12.

[0079]The second embodiment differs from the first embodiment in the fact that the buffer part 300 comprises an elastic ring only. In other words, the tangent probe card according to the second embodiment is not provided with a spring 320. The second embodiment will be detailedly described hereinafter.

[0080]In the second embodiment, the tangent probe card may comprise a probe head assembly with a probe holding portion 120, a holder 200 and an elastic ring 310. For the sake of clarity, the probes are not depicted in FIGS. 11-13. However, the probe head assembly may comprise a plurality of probes according to the above-mentioned embodiments. ...

third embodiment

[0083]FIG. 14 is a perspective exploded view illustrating the third embodiment of the tangent probe card according to the utility model, where the plurality of probes are omitted for the sake of brevity. FIG. 15 is a top view of the tangent probe card according to the third embodiment, wherein the mounting hole of the upper holding block that is used for mounting the spring is illustrated in a perspective view so as to show the location of the spring in the upper holding block. FIG. 16 is a cross-sectional view taken along the line B-B in FIG. 15.

[0084]The third embodiment 3 differs from the first embodiment in the fact that the buffer part 300 comprises the springs only. In other words, the tangent probe card according to the third embodiment is not provided with an elastic ring 310. The tangent probe card according to the third embodiment will be detailedly described hereinafter.

[0085]In the third embodiment, the tangent probe card may comprise a probe head assembly with a probe h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com