Method, System, and Apparatus to Prevent Electrical or Thermal-Based Hazards in Conduits

a technology of electrical or thermal-based hazards and conduits, applied in static indicating devices, protective switch details, instruments, etc., can solve problems such as hazards affecting the safety of conduits, and achieve the effects of reducing the risk of dc arcs, avoiding dc arcs, and avoiding dc arcs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058]Various embodiments of the invention are disclosed in the following detailed description and accompanying drawings. Each drawing teaches how to implement the techniques and / or components to affect the purposes of this patent.

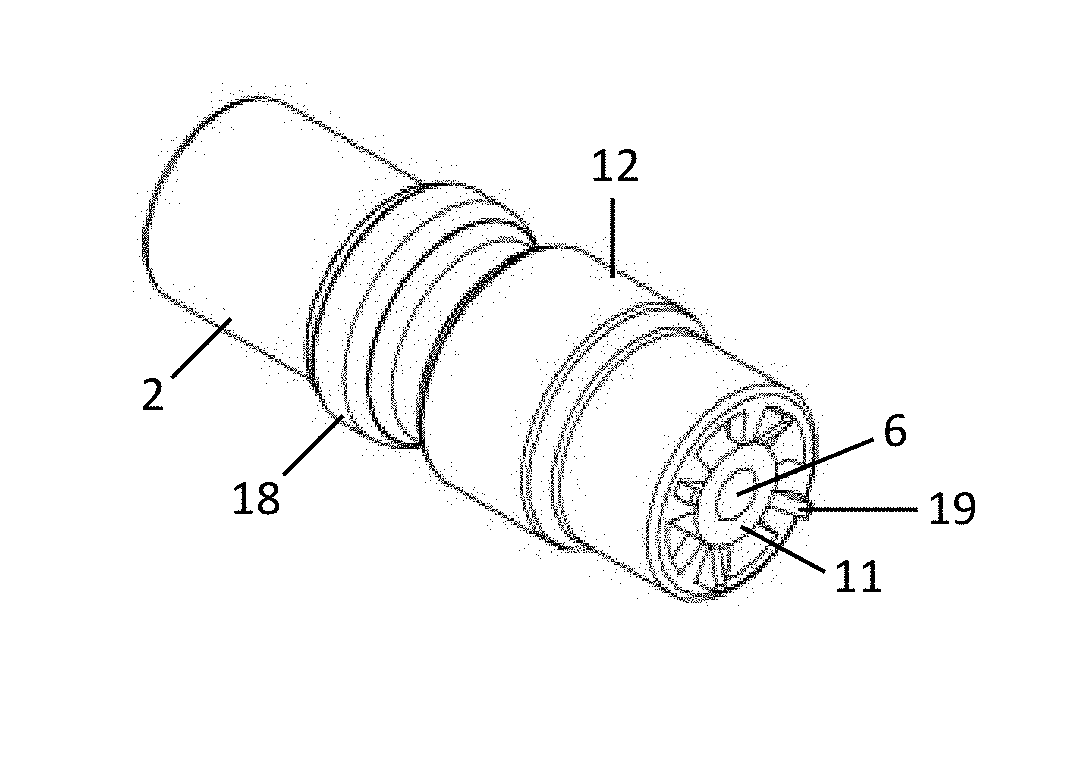

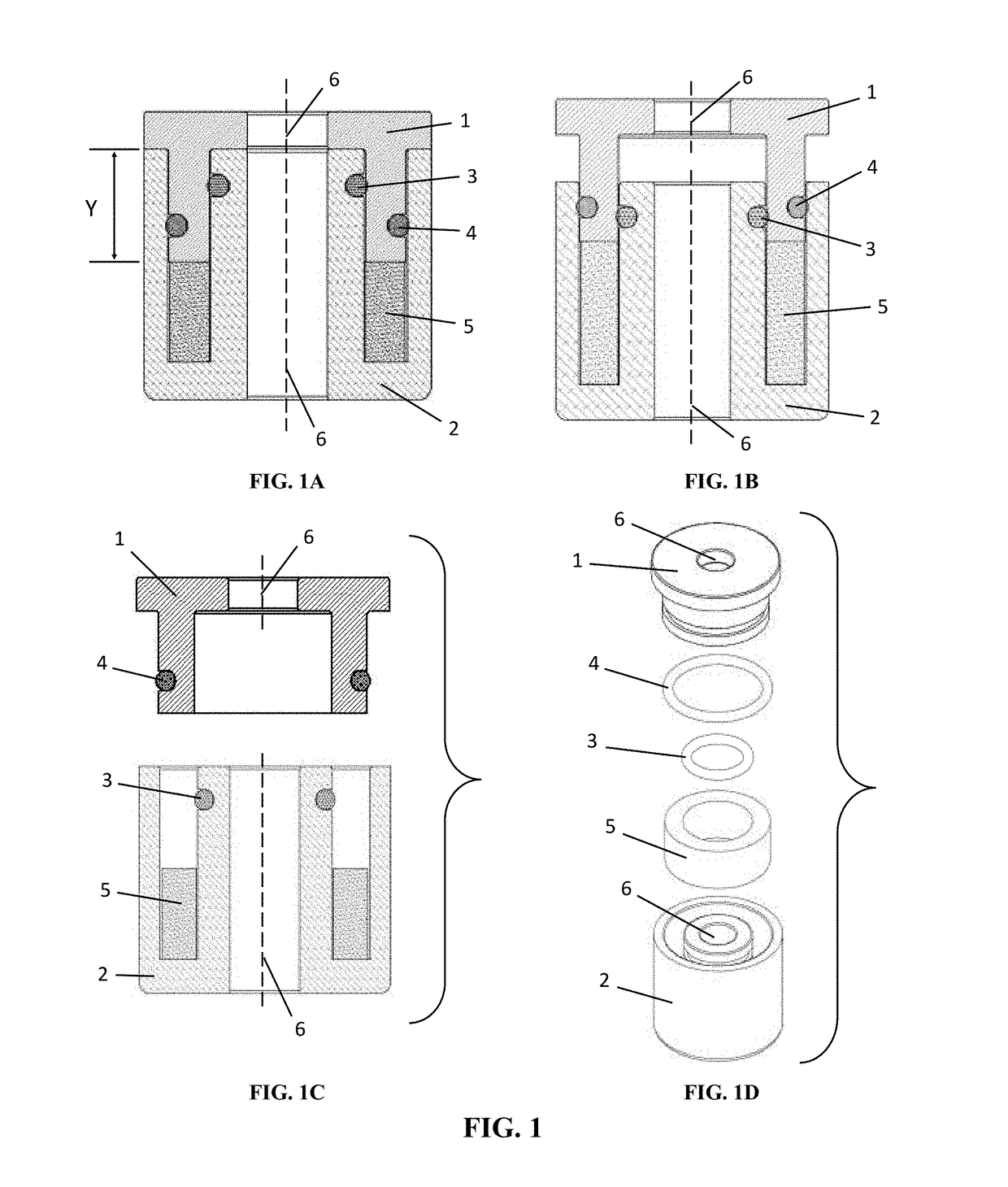

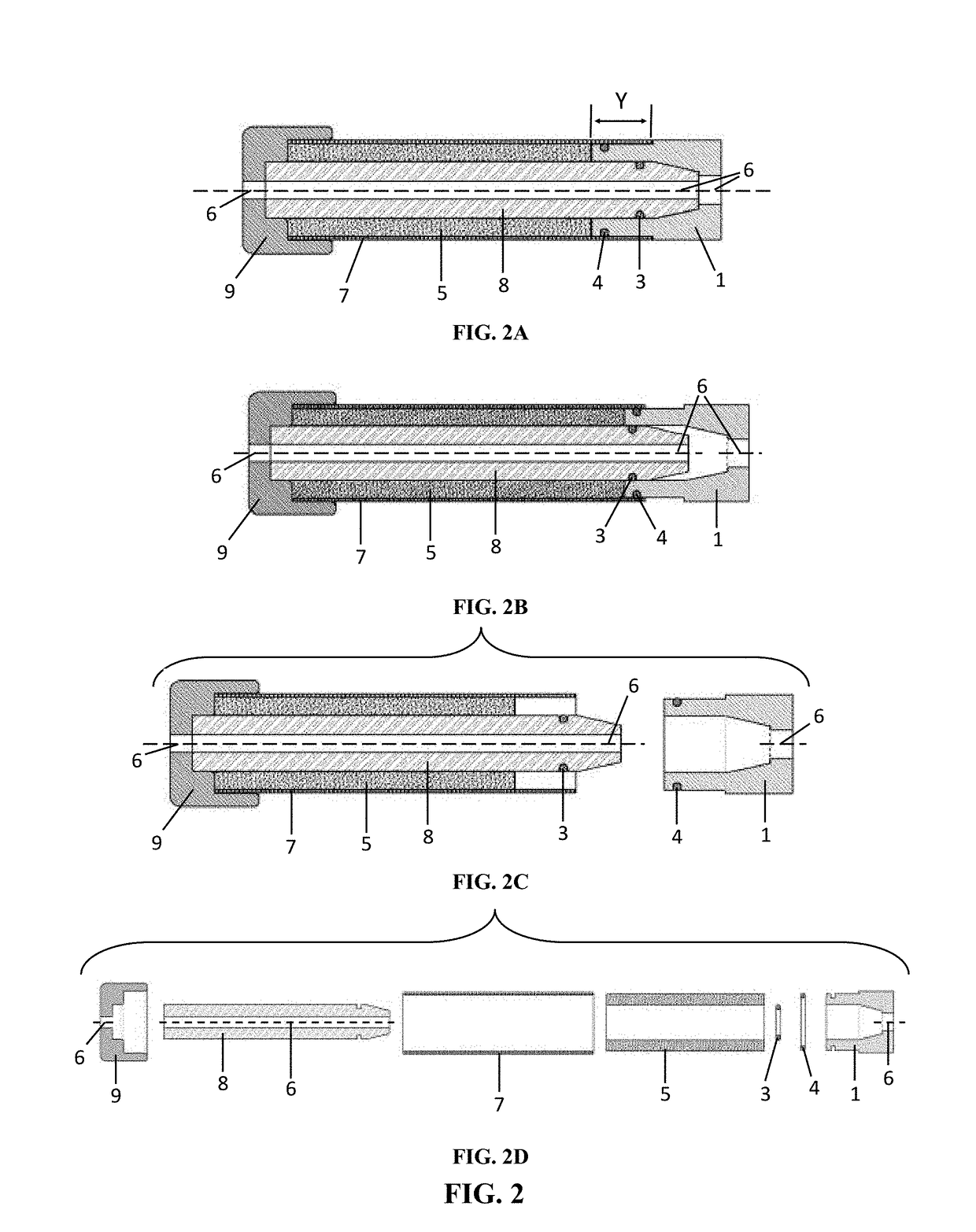

[0059]FIG. 1 is a cutaway assembly drawing with four sub-drawings that depict an embodiment of the current invention. FIG. 1A depicts a cutaway view of a fully assembled connectivity design where a thermovolumetric substance is enclosed within the connectivity body. The image teaches how the components of the connectivity will be arranged when fully assembled. A total of five components are used in the assembly of this connectivity design. Two components comprise the main body of the connectivity, two components act as sealing mechanisms, while the final component is the thermovolumetric substance that expands upon heating. The dimension ‘Y’ represents the displacement distance which the thermovolumetric substance will cause the upper portion of the connec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com