Electrode assembly and flow battery with improved electrolyte distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061]Certain terminology is used in the present description and is intended to be interpreted according to the definitions provided below. In addition, terms such as “a” and “comprises” are to be taken as open-ended.

[0062]Herein, in a quantitative context, the term “about” should be construed as being in the range up to plus 20% and down to minus 20%.

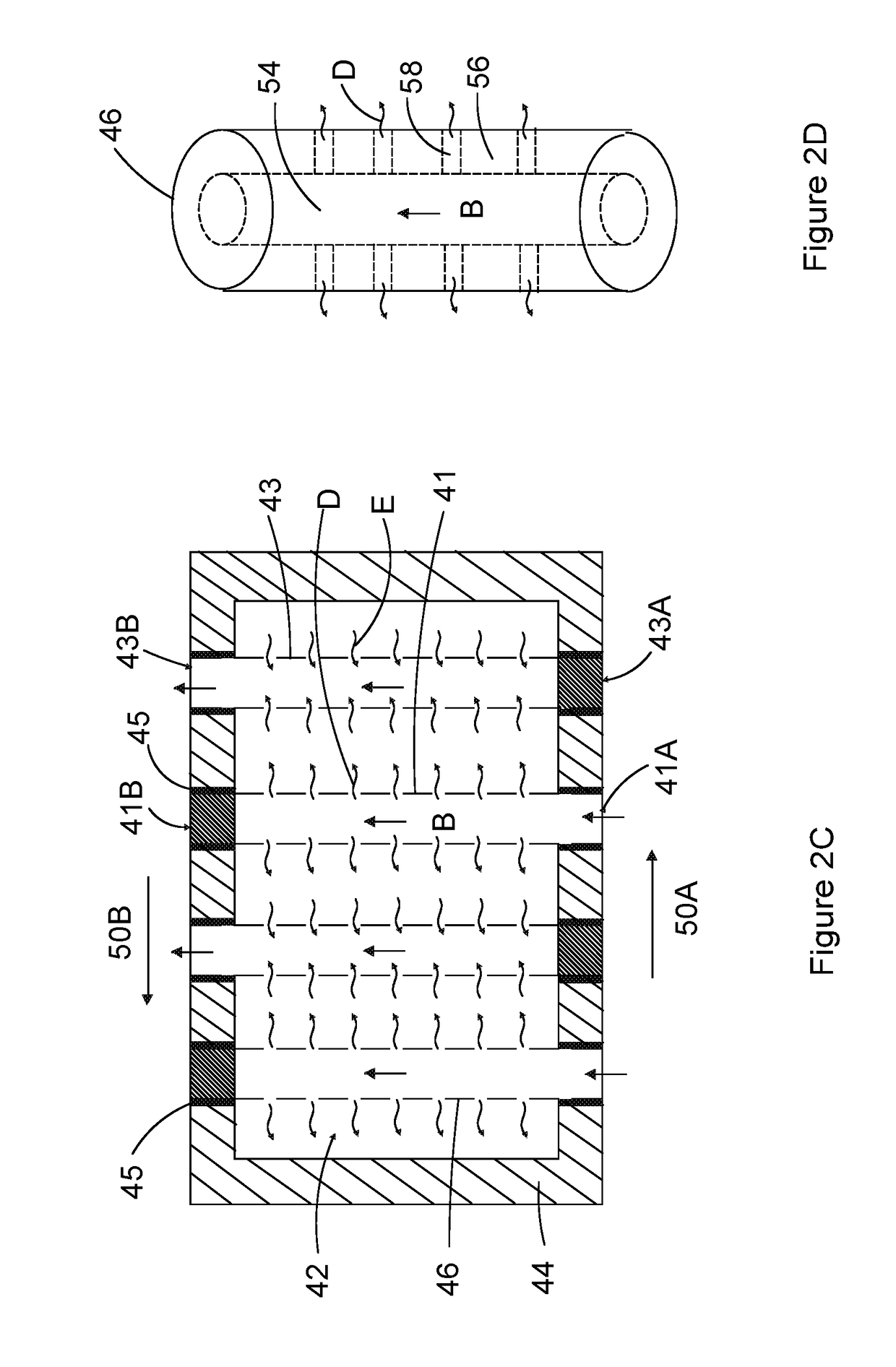

[0063]The term “entirely embedded” is used herein to describe a distributor tube that is placed within the porous material of the electrode such that outer surface of the tube is surrounded by electrode material.

[0064]The term “partially embedded” is used herein to describe a distributor tube that is placed within the porous material of the electrode with at least a portion of the outer surface of the distributor tube not surrounded by electrode material.

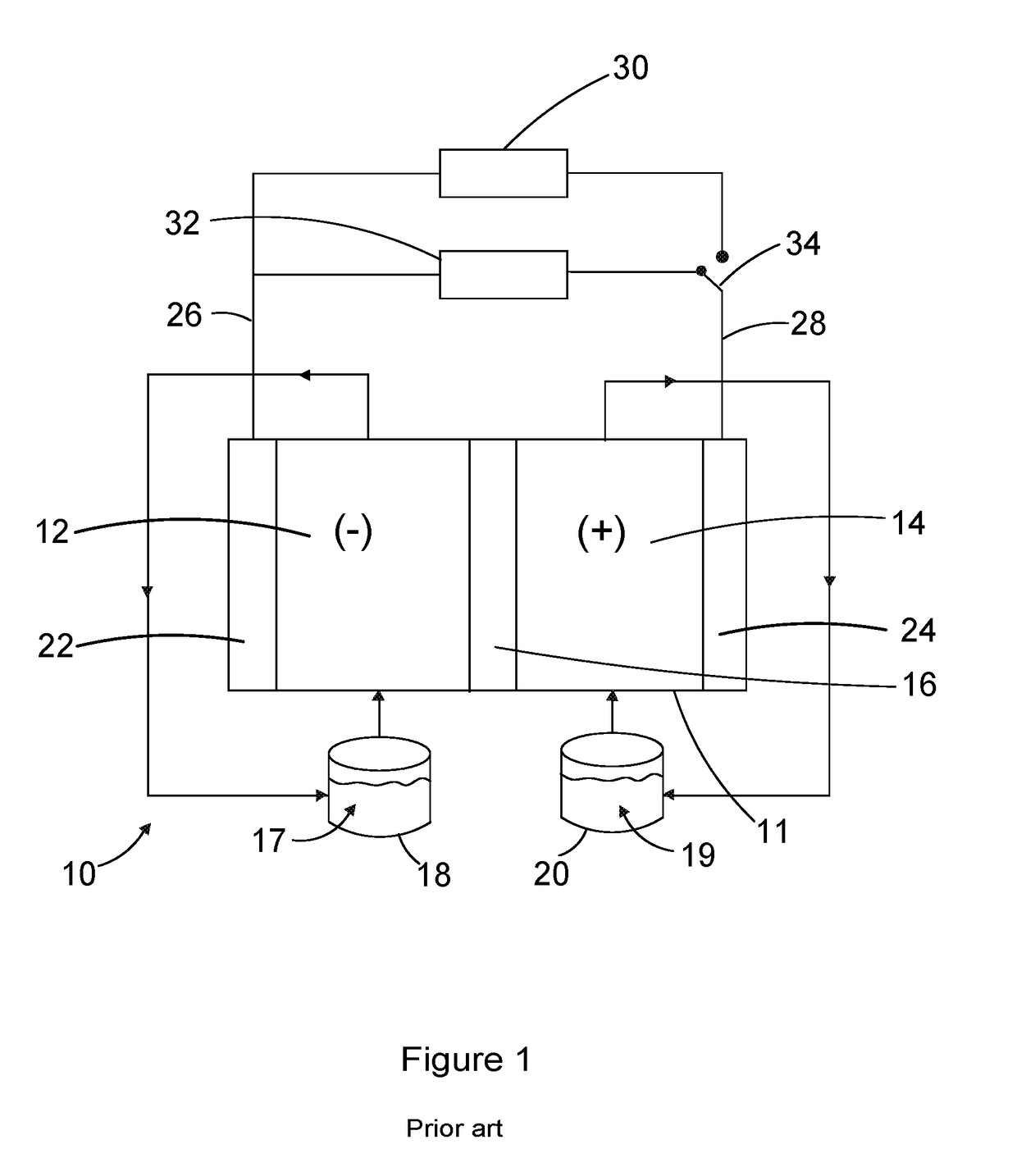

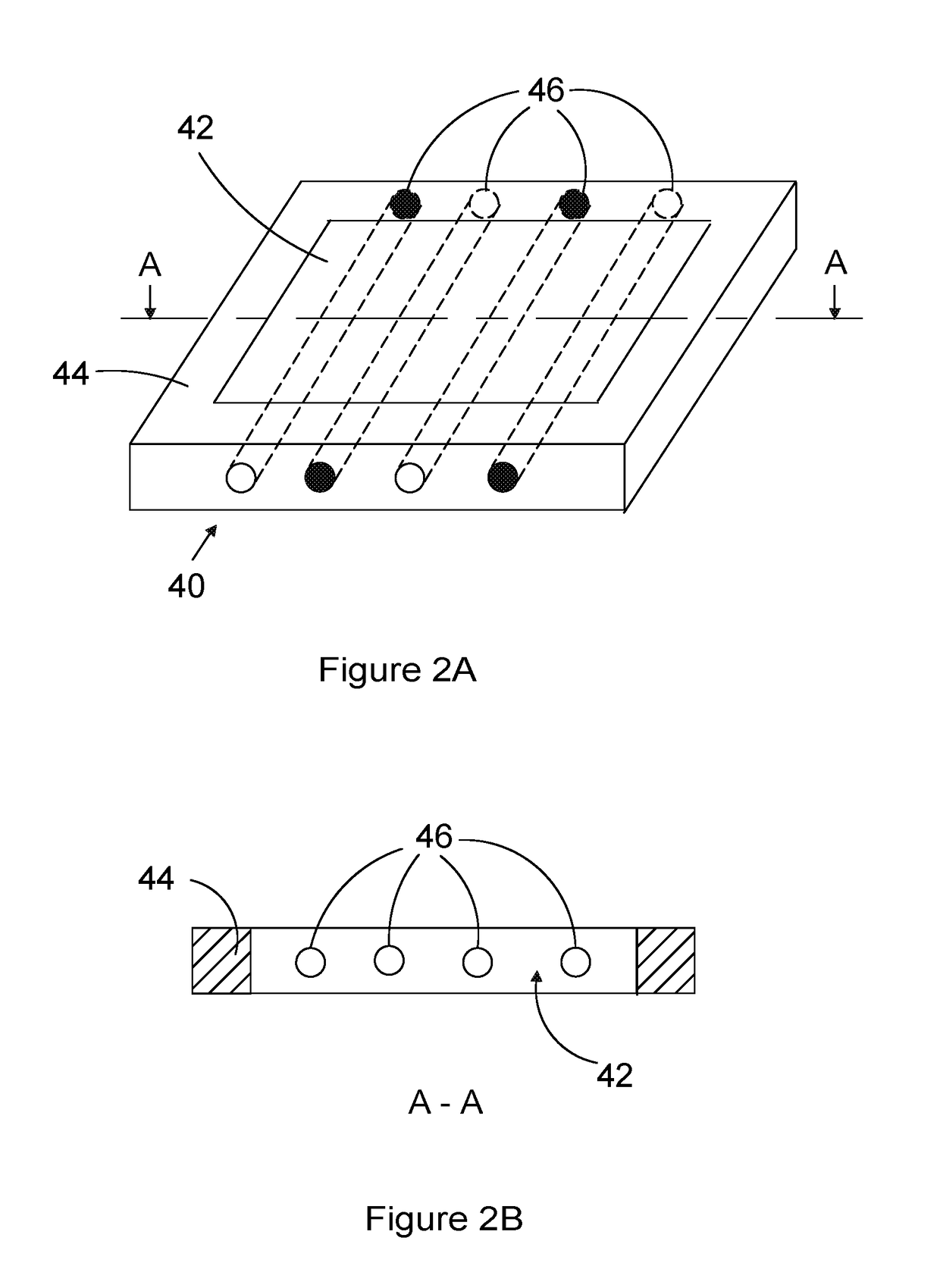

[0065]FIG. 2A shows a schematic view of an electrode assembly according to a preferred embodiment of the invention. Electrode assembly 40 comprises a porous electrode material 42 surro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com