Lean duplex stainless steel and method of manufacturing the same

a duplex stainless steel and duplex technology, applied in the field of lean duplex stainless steel, can solve the problems of increasing manufacturing costs, many limitations of 400 series stainless steel in its use as a thick plate, and its formability does not reach the level of 300 series stainless, so as to minimize or exclude the alloying elements, reduce the manufacturing cost of duplex stainless steel, and save resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

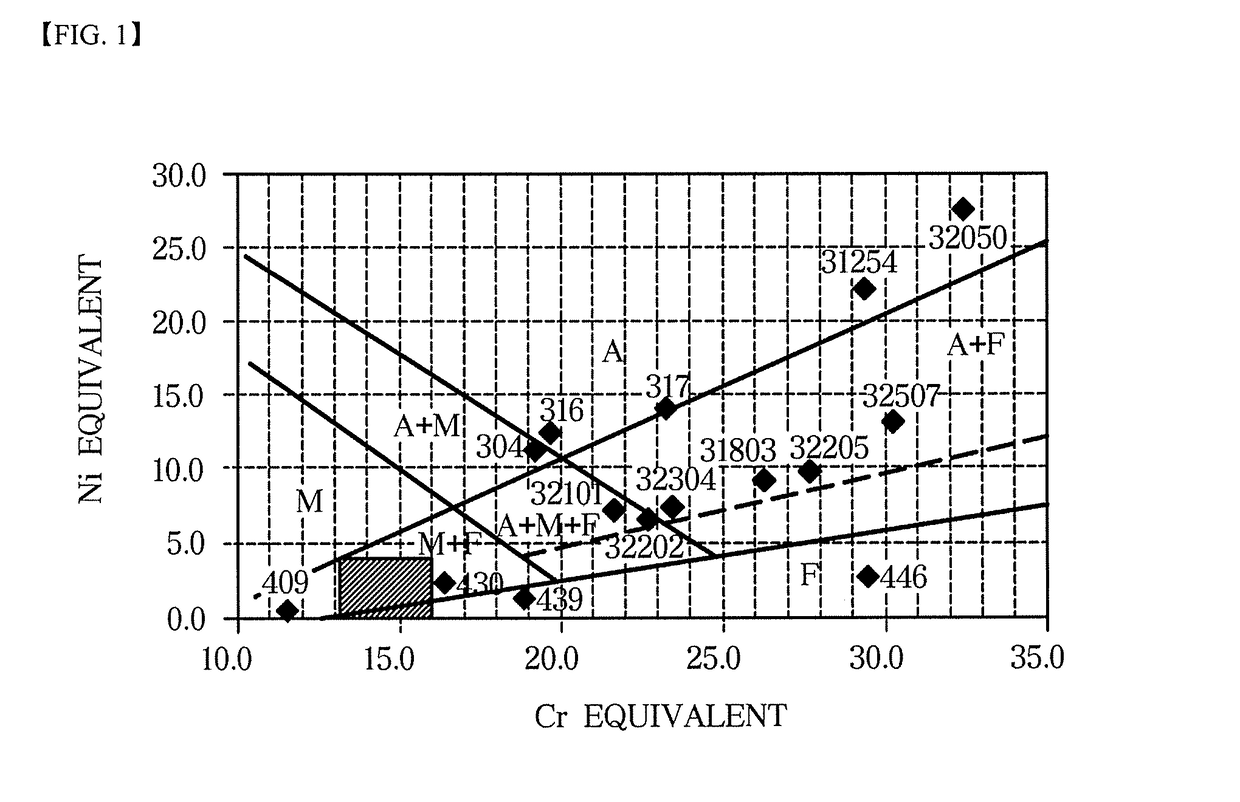

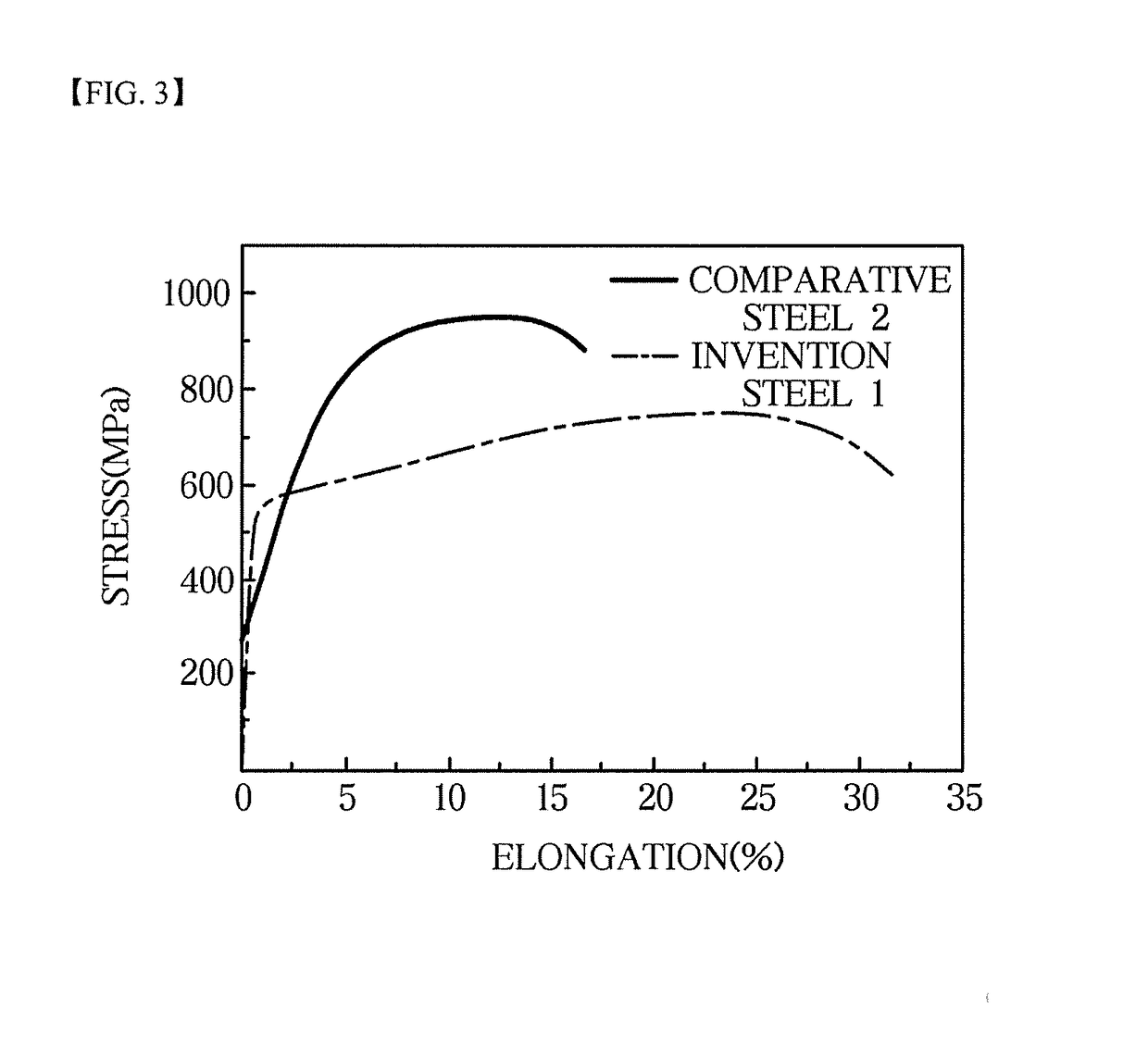

[0033]A lean duplex stainless steel according to an embodiment of the present invention comprises, by weight percent, 0.05 to 0.1% of carbon (C), 2.0 to 4.0% of silicon (Si), 4.0 to 8.0% of manganese (Mn), 13.0 to 15.0% of chromium (Cr), 0.05 to 0.15% of nitrogen (N), with the remainder being iron (Fe) and other unavoidable impurities.

MODE FOR INVENTION

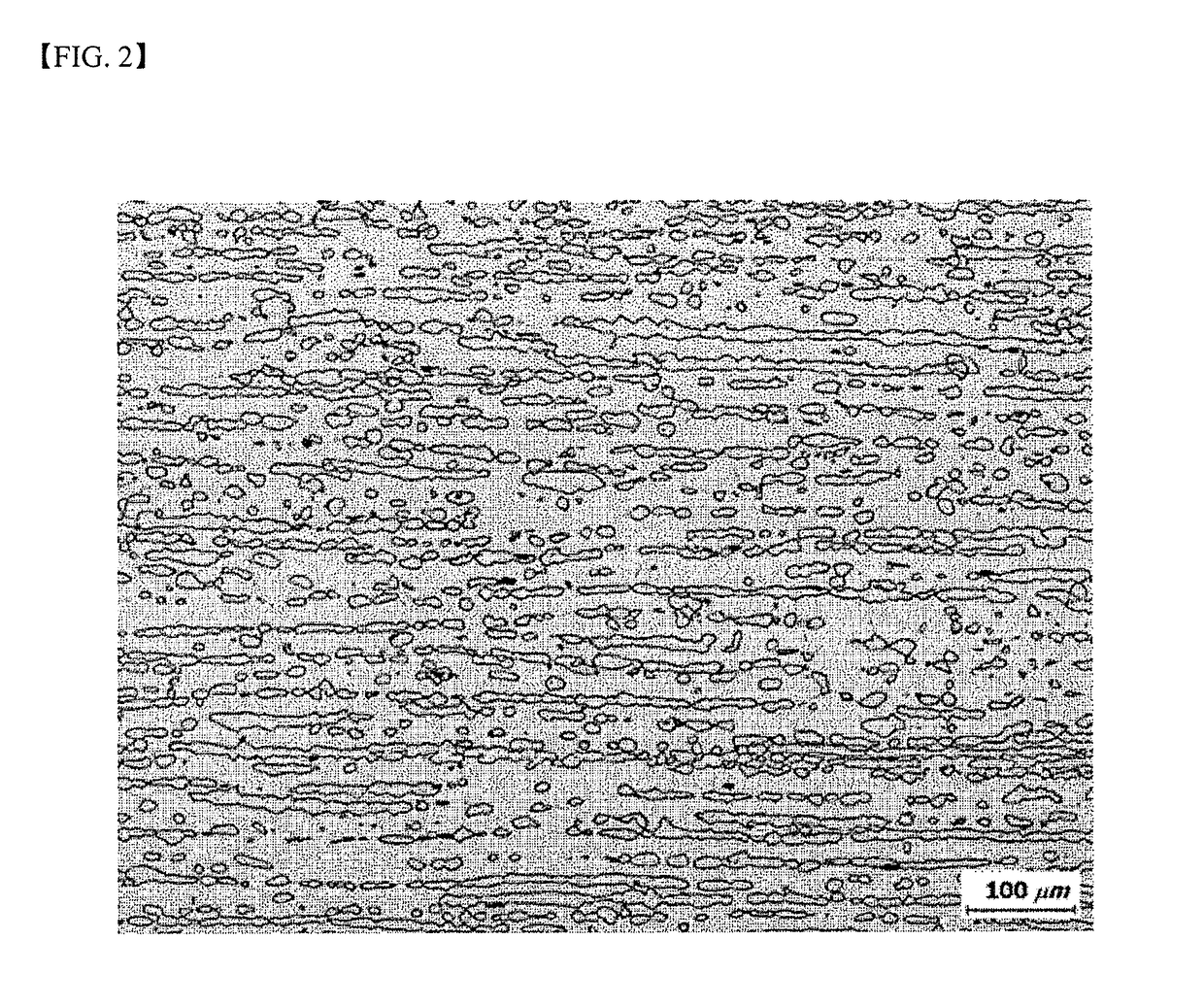

[0034]Hereinafter, embodiments of the present invention will be described in detail with reference to the accompanying drawings.

[0035]The following embodiment is presented to fully convey the idea of the present invention to those skilled in the art to which the present invention belongs. The present invention is not limited to the embodiments shown herein but may be embodied in other forms. In order to clarify the present invention, the drawings may omit the showing of parts not related to the description, and the size of the components may be slightly expressed in a somewhat exaggerated manner to facilitate understanding.

[0036]A lea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com