Low yield ratio and high-strength steel having excellent stress corrosion cracking resistance and low temperature toughness

a high-strength steel and low yield ratio technology, applied in the field of low yield ratio and high-strength steel, can solve the problems of degrading stress corrosion cracking (scc) resistance, low economical efficiency of steel for manufacturing gas tanks, etc., and achieve excellent stress corrosion cracking resistance and low temperature toughness. , the effect of low yield ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026]Hereinafter, preferred embodiments of the present disclosure will be described. However, the embodiments of the present disclosure may be modified into various other forms, and the scope of the present disclosure is not limited to the embodiments described below. Embodiments of the present invention are provided so that those skilled in the art may more completely understand the present invention.

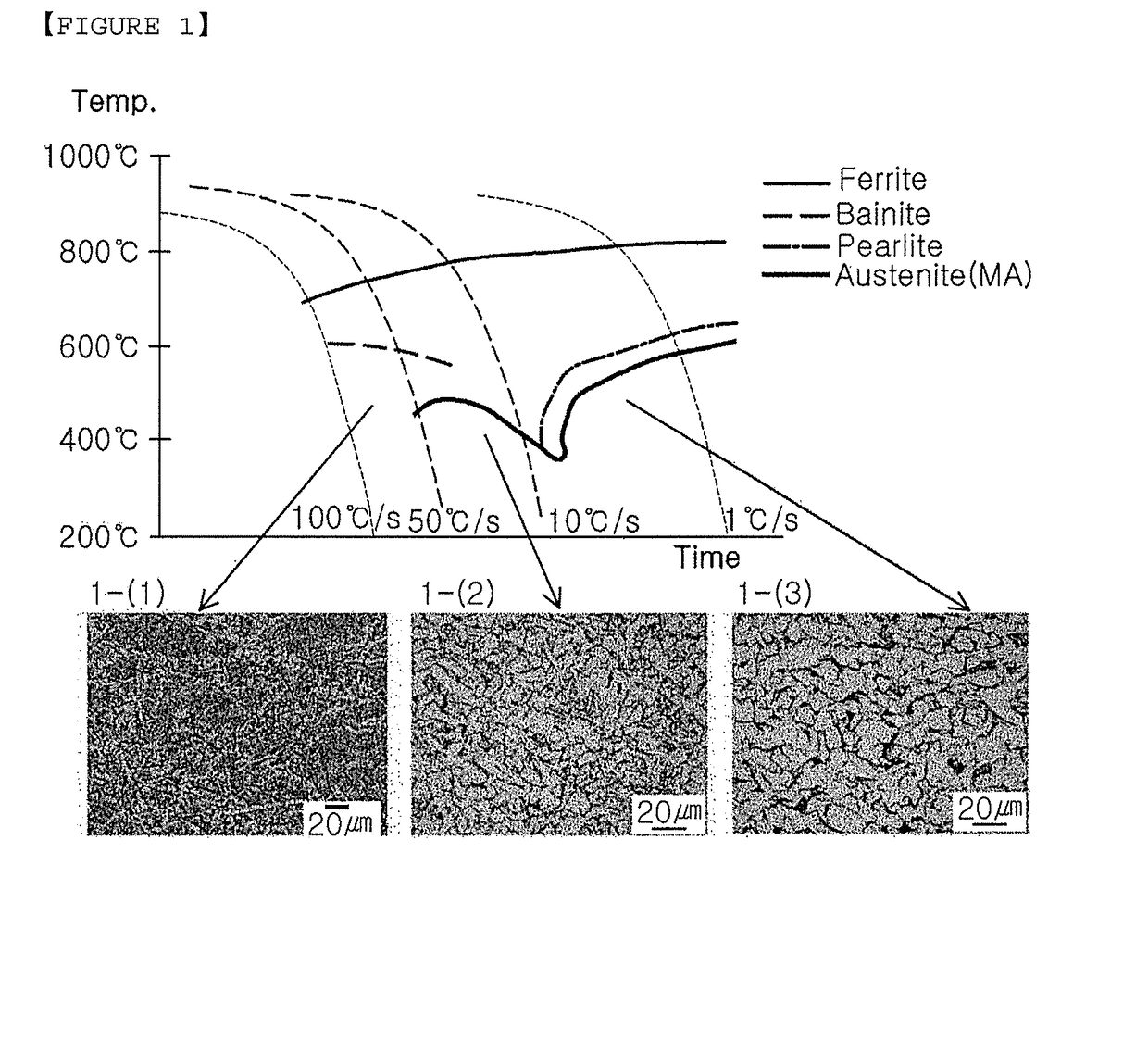

[0027]The inventors of the present application recognized that it is difficult to make both ammonia stress corrosion cracking resistance and low temperature toughness excellent and have studied to solve the problem.

[0028]As a result, the inventors confirmed that it is possible to provide a low yield ratio and high-strength steel having excellent stress corrosion cracking resistance and low temperature toughness by controlling an alloy composition and a microstructure and a manufacturing method thereof, thereby completing the present disclosure.

[0029]Hereinafter, a low yield ratio and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| circle diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com