Post-tensioning apparatus and system for structures

a technology of post-tensioning apparatus and system, which is applied in the direction of construction, building repair, building reinforcement, etc., can solve the problems of low stability of cement patches, high risk of repeated failure of cement patches, and difficulty in adjusting the strength of cement patches, so as to achieve a higher localized concentration of stress and strengthen structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

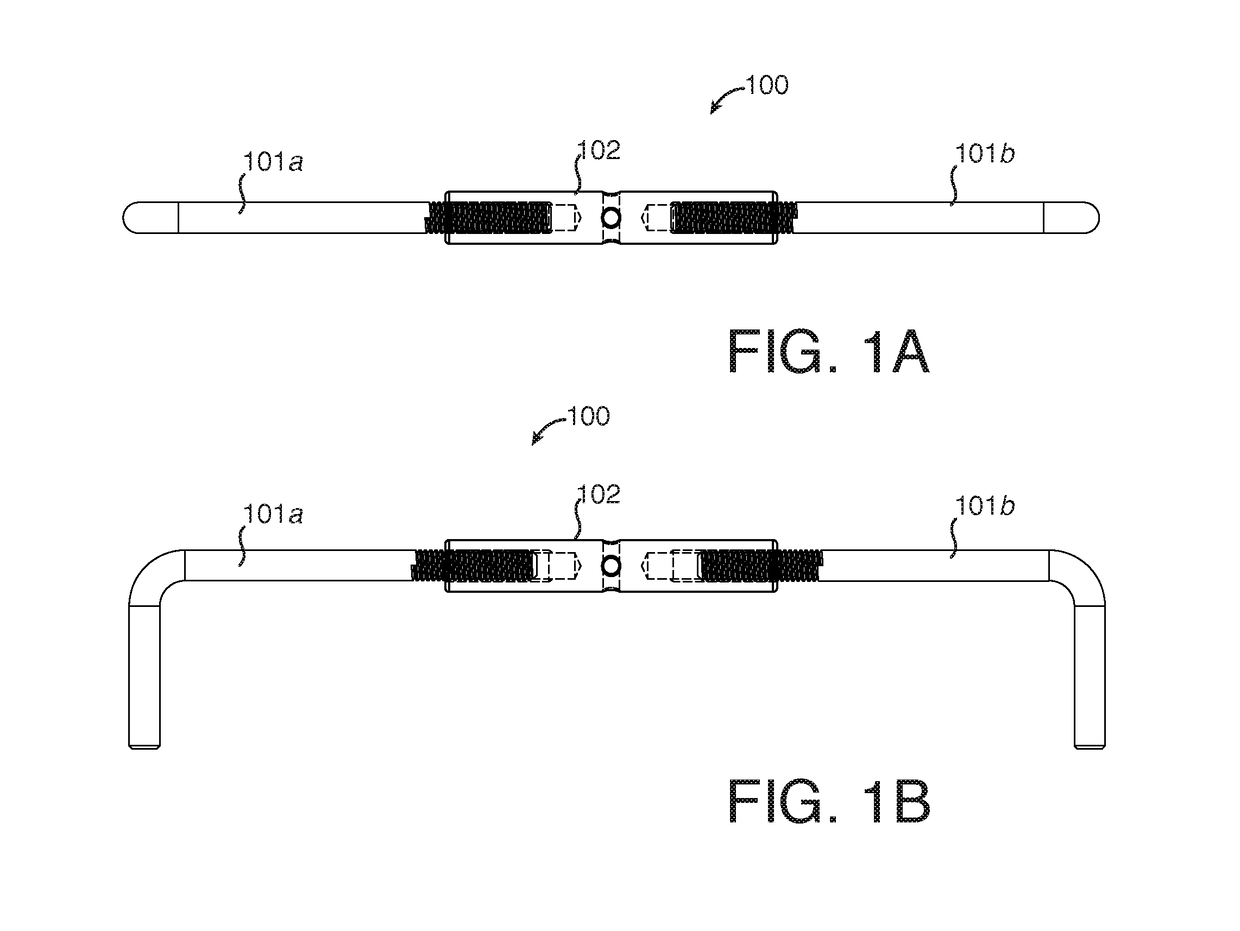

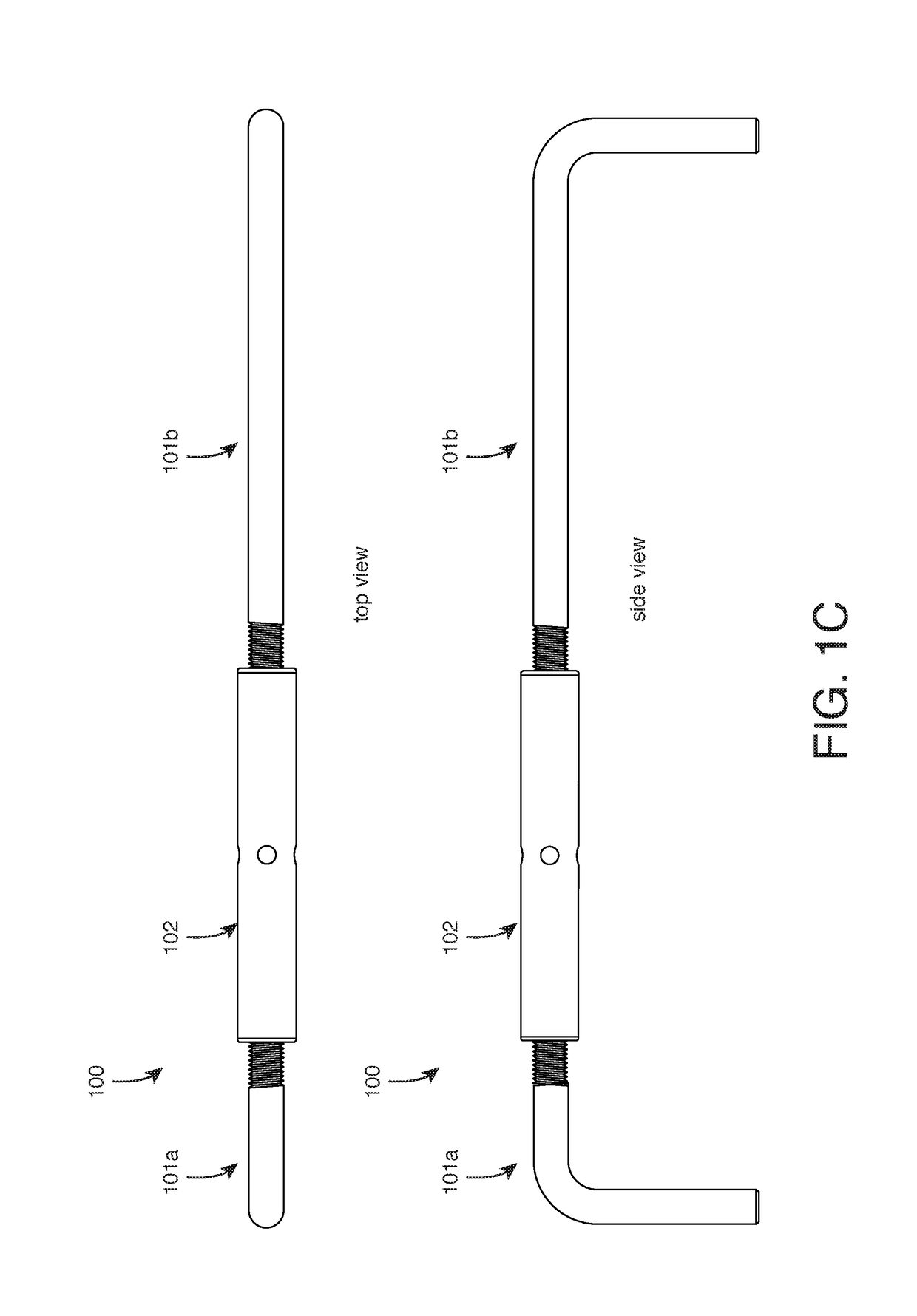

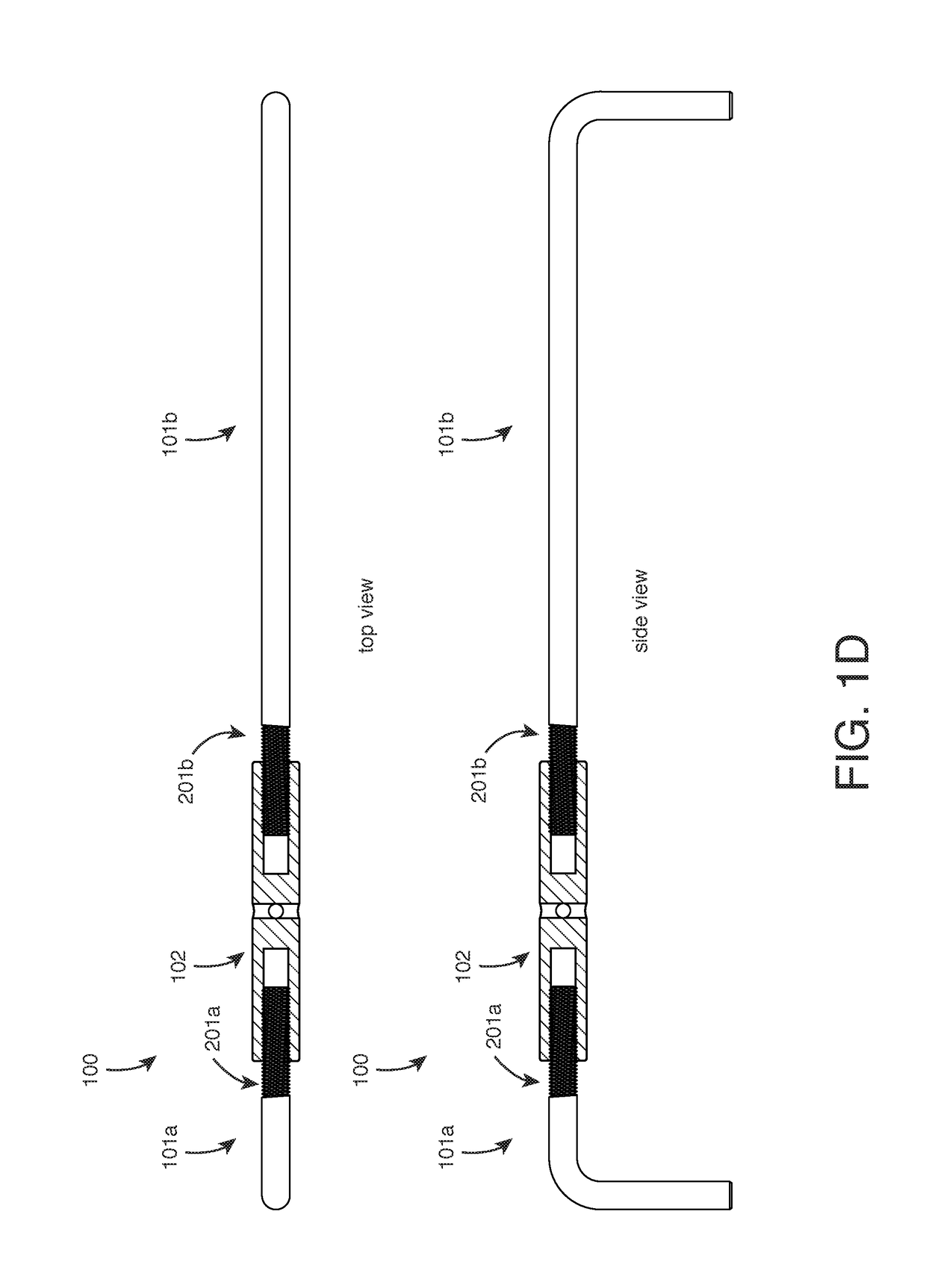

[0053]Embodiments of the present disclosure may be used in a system comprising at least one tensioning mechanism and at least two tension application components. Furthermore, different tensioning components may be used interchangeably with a tensioning mechanism to allow system customization for each application.

[0054]In certain embodiments of the present invention, a modular apparatus and system provides tension to existing structures, such as an existing concrete installation, wherein it is desired to provide structural reinforcement. Tensioning may be desired in many scenarios such as the cross-linking of independently poured concrete installations or providing tension in “post-tensioning” to repair a concrete installation using tensile strengthening features. The application of metal structure for the tensile reinforcement is typically placed across a mechanical failure zone such as a fissure or crack where the concrete installation has mechanically failed.

[0055]An apparatus 100...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com