Electric gear pump

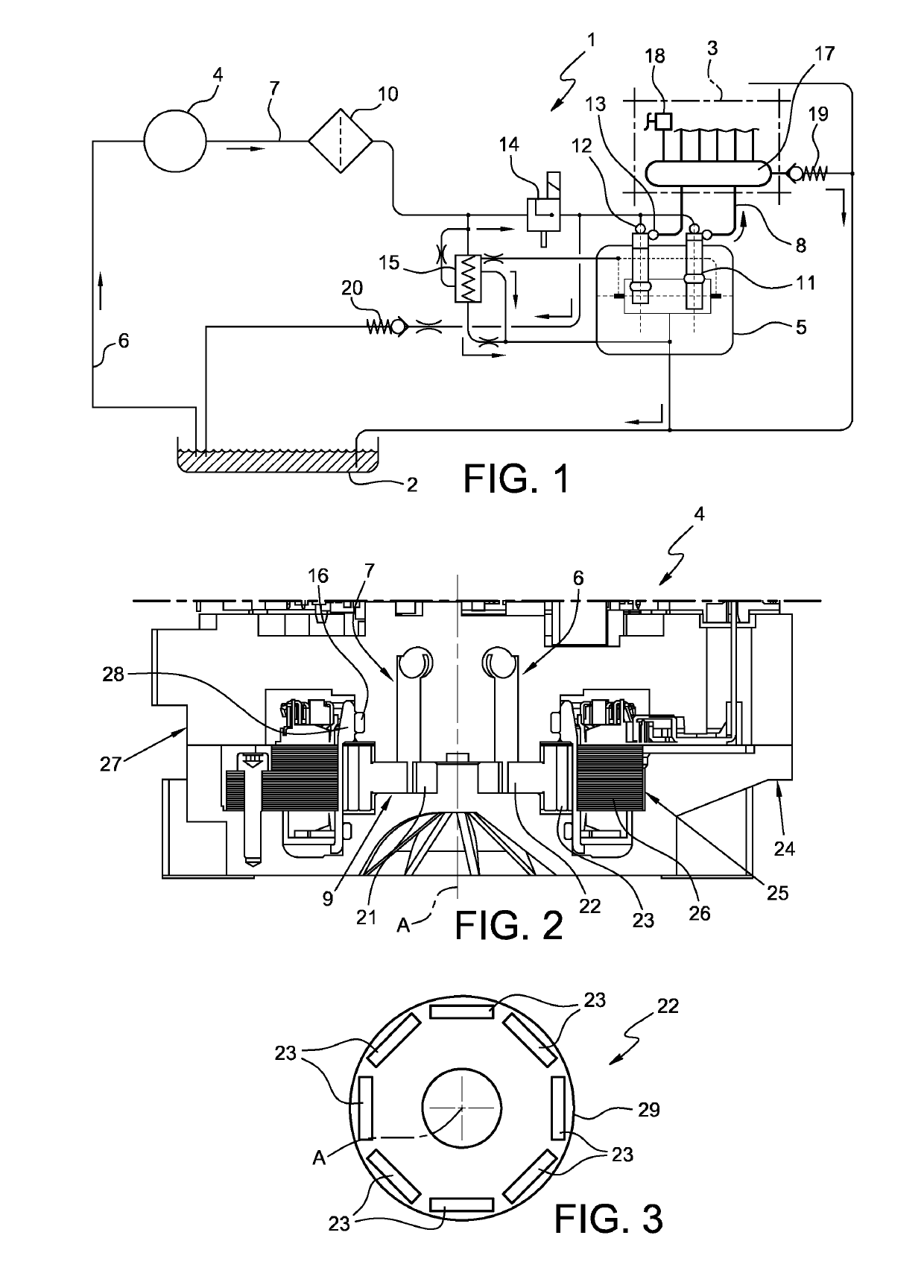

a gear pump and electric technology, applied in the direction of rotary/oscillating piston pump components, machines/engines, liquid fuel engines, etc., can solve the problems of difficult placement of magnets inside the internal spur rotor as described above, and the internal surface of mechanical machining of the external surface of the rotor does not always achieve the circularity tolerance required. , to achieve the effect of improving the circularity and simple and quick positioning of magnets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

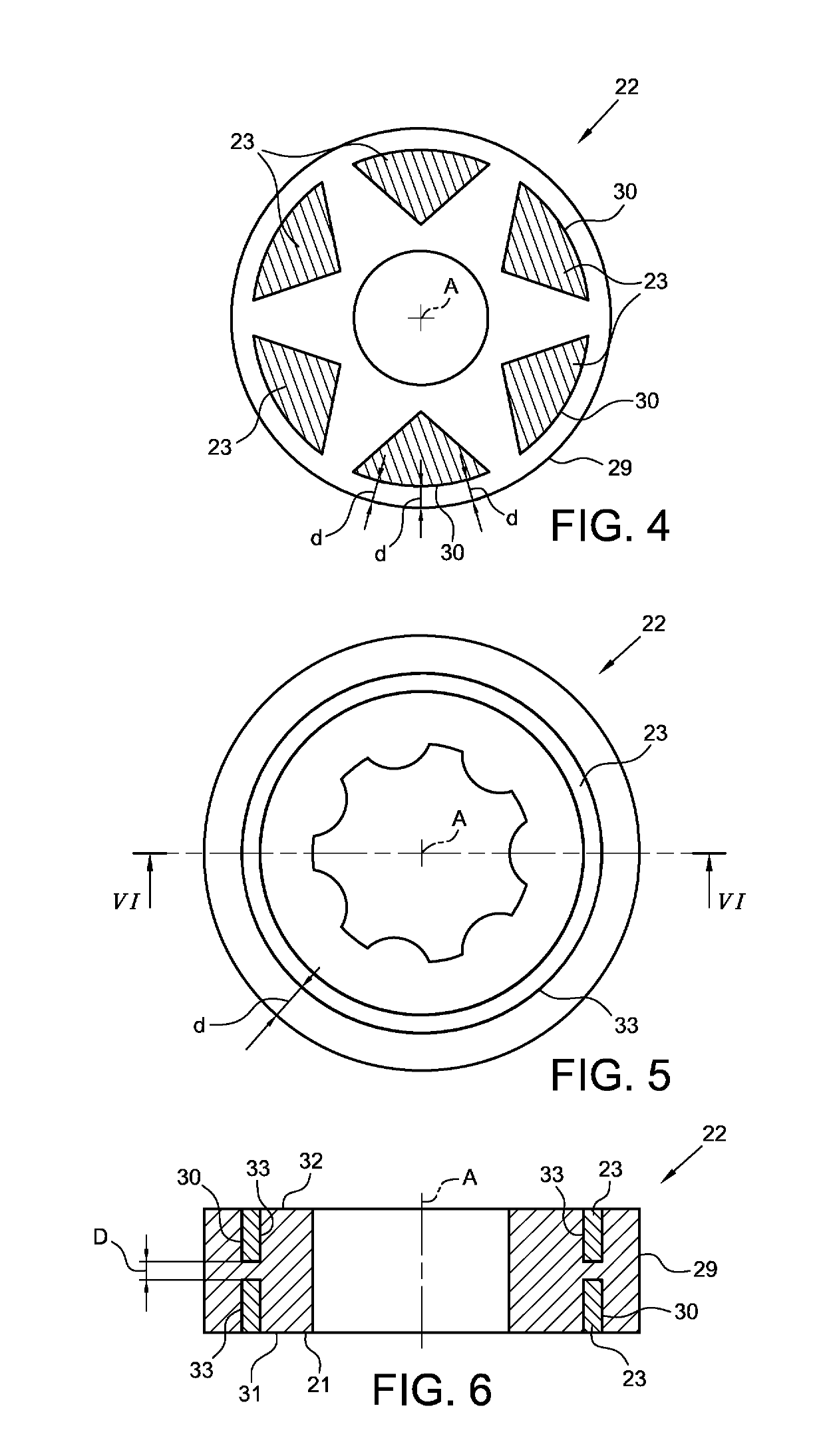

[0054]FIG. 4 is a schematic view of an internal spur rotor 22 according to the invention in which homogeneous distribution of material, or a constant distance d measured radially, is guaranteed between the magnets 23 and the corresponding portions of the external surface 29 of the internal spur rotor 22. This technical effect is achieved in the embodiment of FIG. 4 by virtue of a plurality of magnets 23 arranged along the circular periphery of the internal spur rotor 22 in which said magnets have an external surface 30 which, viewed from a plane orthogonal to the axis A, coincides with an arc of a circle centred on said axis A.

[0055]Such magnets may be provided embedded in the internal spur rotor 22 or inserted in special seats made on the lower and / or upper surface of the internal spur rotor 22. For the sake of clarity in FIG. 4, the internal spurs of the rotor 22 have not been shown.

second embodiment

[0056]FIG. 5 is a schematic view of an internal spur rotor 22 according to the invention in which homogeneous distribution of material, or a constant radial distance d, is guaranteed between the magnets 23 and the external surface 29 of the internal spur rotor 22. According to this embodiment, the magnets 23 are made in the form of a ring concentric with the axis A so as to guarantee along the internal periphery of the internal spur rotor 22 a homogeneous distribution of material, or a constant radial distance d, between the magnets 23 and the external surface 29 of the rotor.

[0057]FIG. 6 is a view in section of the internal spur rotor of FIG. 5 along the section line VI-VI. As can be seen, according to this embodiment, the internal spur rotor 22 comprises a first annular seat 33 made on the upper surface 32 and a first annular seat 33 made on the lower surface 31, in which said seats 33 are aligned in the axial direction A.

[0058]The distance between the seats in the axial direction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com