Method for fabricating timepiece components including a decorative coating of aventurine

a technology of aventurine and decorative coating, which is applied in the field of fabricating timepiece components including aventurine decorative coating, can solve the problems of difficult preparation and assembly of aventurine dials, unusable thin slices, and large waste of aventurine dials, and achieves the effect of improving the level of the upper surface, facilitating the process, and generally good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

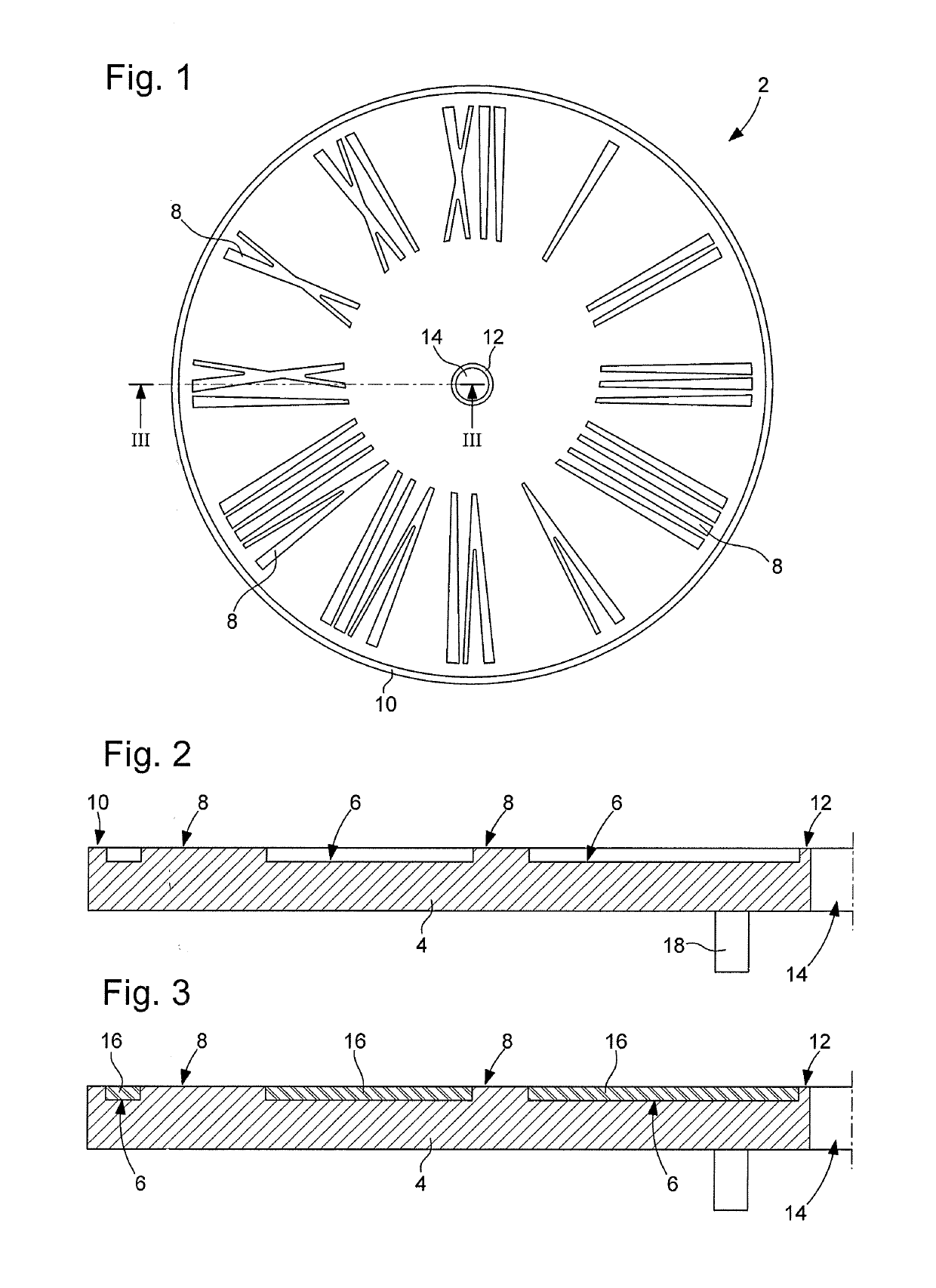

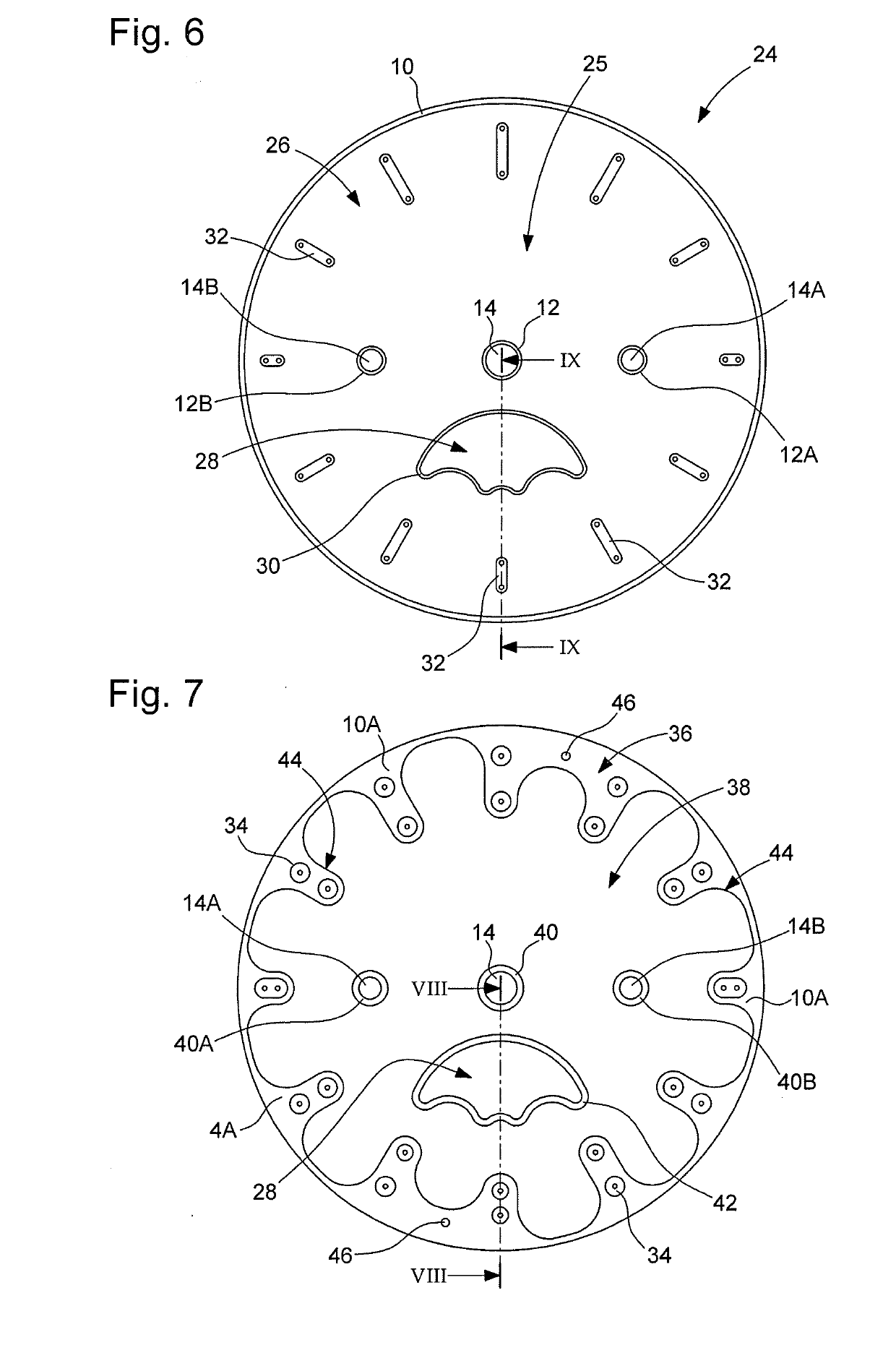

[0036]Referring to FIGS. 1 to 5, there will be described an implementation of the method for fabricating a display element, in particular a watch dial, according to the invention.

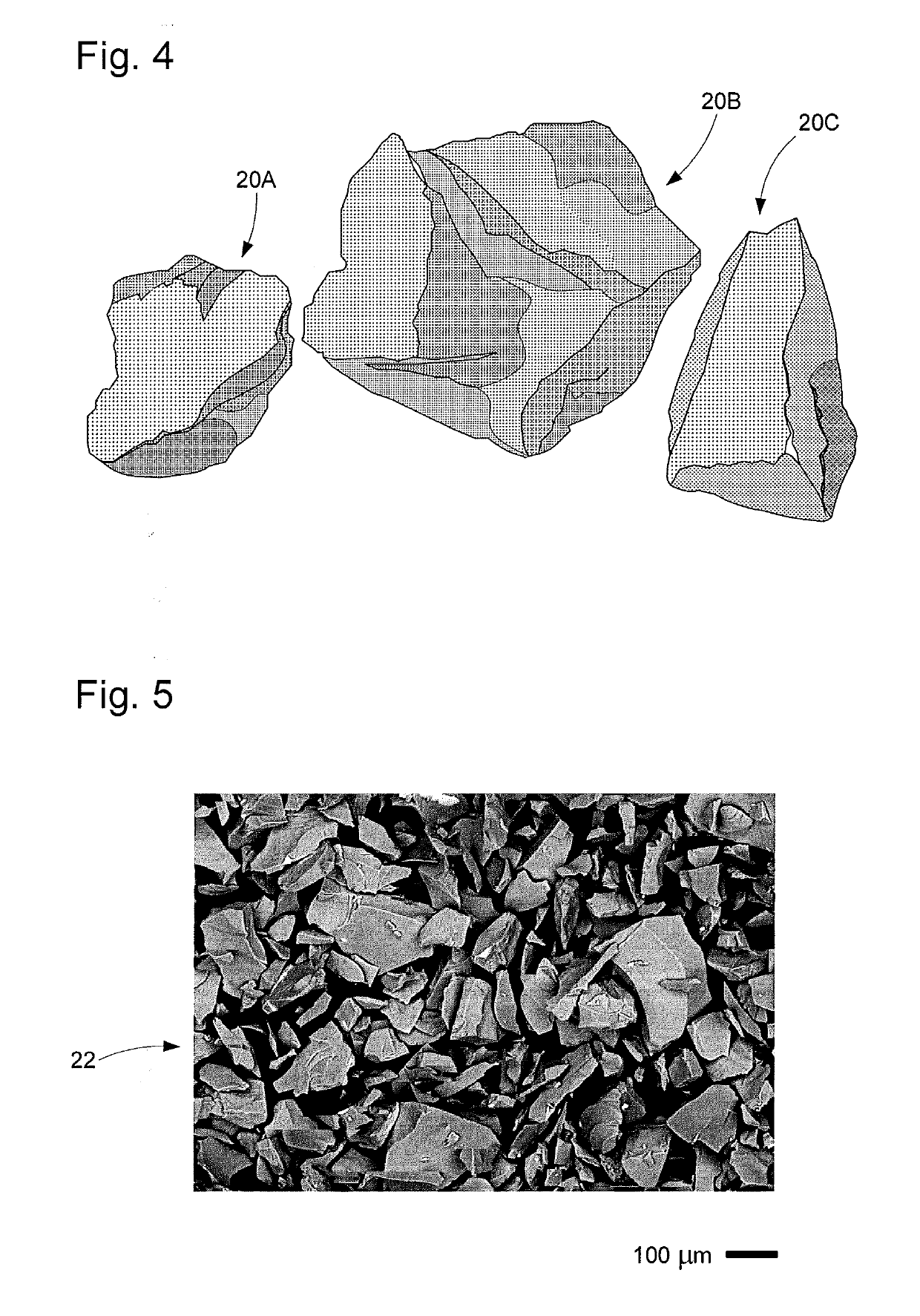

[0037]To fabricate dial 2, firstly, there is made a support 4 with a stiff base having the general shape of a disc. This support 4 is formed of a material having a melting temperature higher than 1000° C. A surface 6, intended to receive a decorative coating, is machined in the support on its upper side, i.e. on the side of the dial that is visible once incorporated inside a watch case. In the variant represented in the Figures, the support is metal, particularly made of gold or silver, and has motifs 8 intended to be visible in the finished product, these motifs being integral with the base of the support. In this variant, motifs 8 are the Roman numerals from I to XII. Thus, the number of motifs is relatively high and some of these motifs, namely the V and the X, have a contour with a complex shape with sh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com