Geothermal system operable between heat recovery and heat storage modes

a geothermal system and heat storage technology, applied in geothermal energy generation, domestic heating, light and heating apparatus, etc., can solve the problems of difficult control of the connection zone between the wells, high cost of drilling the wells, and difficulty in properly connecting the two wells at depth, so as to improve the overall efficiency of heat recovery throughout the thermal storage and recovery process, and recover heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

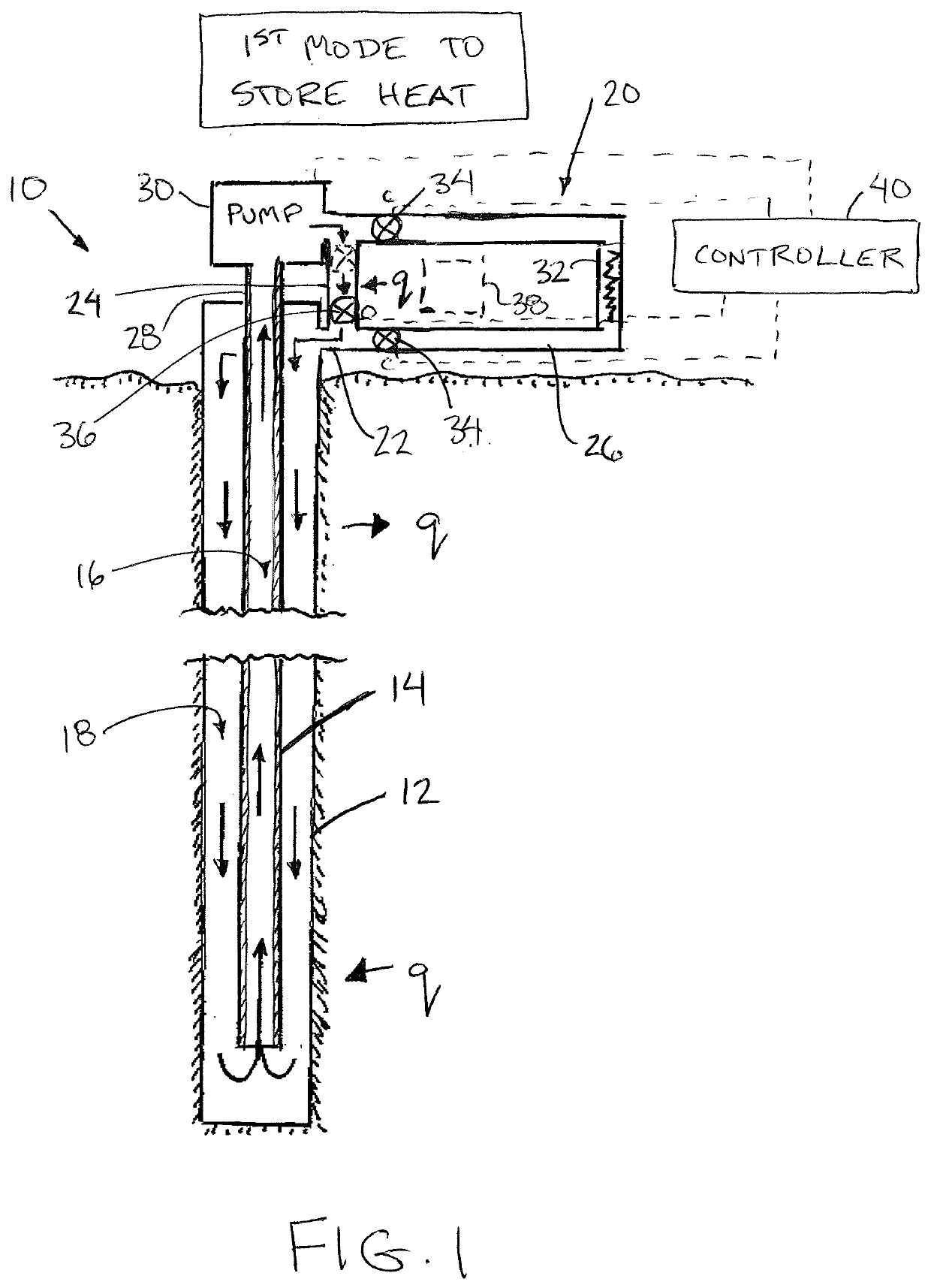

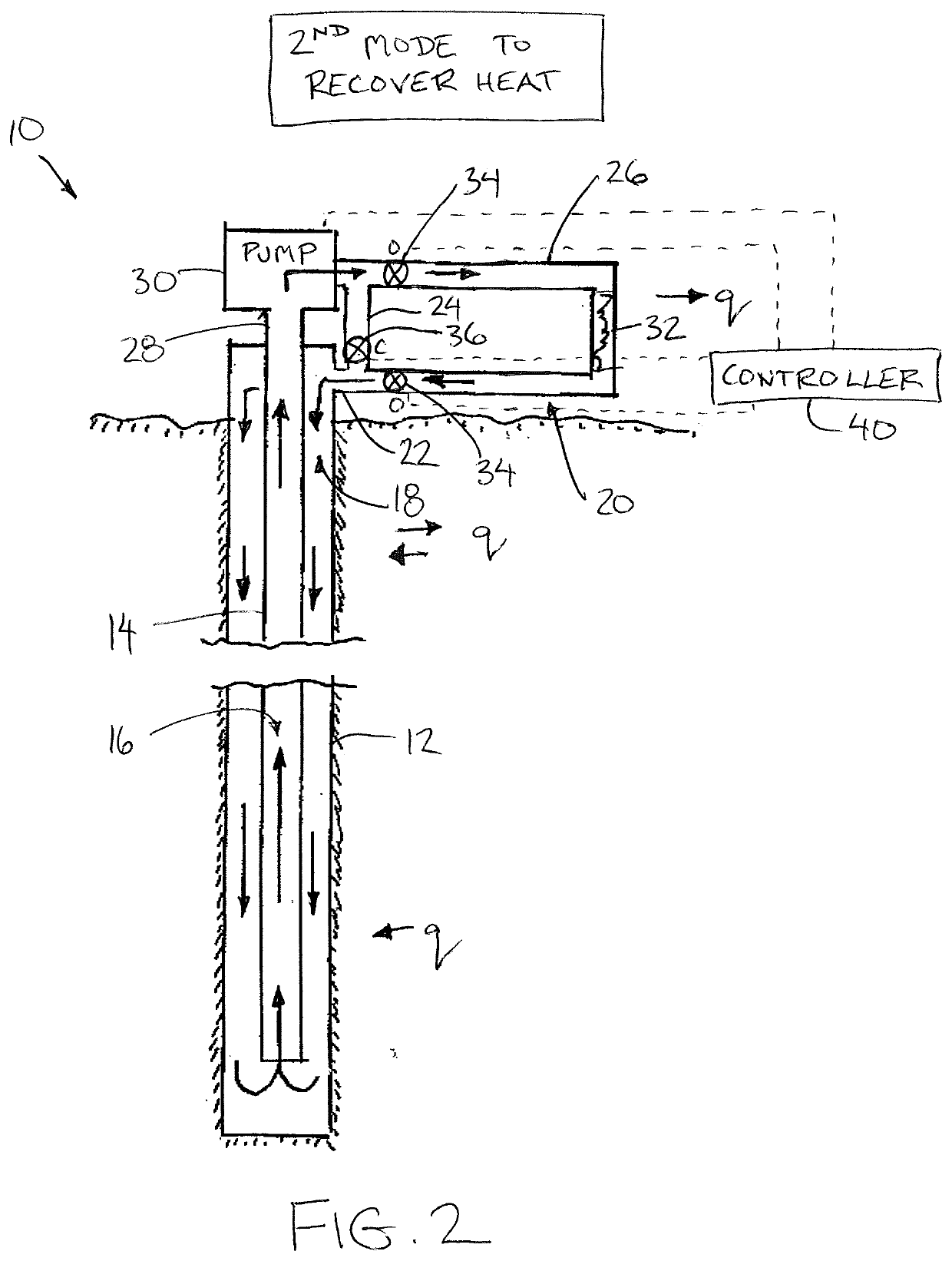

[0044]Referring to the accompanying figures there is illustrated a geothermal system 10 installed in the ground such that the ground is used as a heat source and / or heat sink. In the illustrated embodiment, the geothermal system is installed within a reclaimed hydrocarbon wellbore in which the existing well casing of the wellbore defines an outer pipe 12. The well casing is plugged at a location above a production zone of the wellbore to define a bottom end of the outer pipe 12 such that the outer pipe extends longitudinally downward from a top end at a surface of the ground heat source to the bottom end which is closed. Alternatively, any borehole formed in the ground and lined with an outer pipe may be used.

[0045]An inner pipe 14 is installed within the outer pipe 12 in which the inner pipe has an outer diameter which is less than the inner diameter of the outer pipe so as to define an annular space between the inner and outer pipes extending along the length of the pipes. The inn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com