Analyte sensors having a signal-to-noise ratio substantially unaffected by non-constant noise

a technology of analyte sensor and non-constant noise, applied in the field of analyte sensor, can solve the problems of likely diabetic behavior, inhibiting the ability of diabetics to make educated insulin therapy decisions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0435]Resistance Domain Configurations to Increased the Analyte Signal Reduce Non-Constant Noise

[0436]Transcutaneous sensors, with electrode, interference, enzyme and resistance (polyurethane blend) domains, were built and tested in non-diabetic hosts. The control and test sensors were built as described in U.S. Publication No. 2006-0020187, which is incorporated herein by reference in its entirety, with the following exception: the resistance domain of the test sensors was formed of 3 layers of a 60% ChronoThane® H (CardioTech International, Wilmington, Mass., USA; the PEO concentration of ChronoThane® H is about 25%) polyurethane blend solution, as compared to a single layer of a 45% ChronoThane® H polyurethane blend solution in the control sensors. Test and control sensors were implanted bilaterally in the abdomens of non-diabetic host volunteers, for a period of about 7 days.

[0437]FIG. 8 illustrates exemplary test results from one test sensor, over a period of about 7 days, afte...

example 2

[0440]A Lubricious Coating Configured to Reduce Non-Constant Noise

[0441]Control and test sensors, with electrode, enzyme and resistance domains, were built as described in U.S. Patent Publication No. US-2006-0020187-A1, including a resistance domain formed using a polyurethane polymer blend having about 8 wt. % PEO, as described in the section entitled “Polyurethane Polymer Material” above. A lubricious coating was applied to the test sensors by dipping them one time into a solution of HydroMed™ (CardioTech International, Inc., Wilmington, Mass., USA) and drying. The control and test sensors were tested in vitro (see Table 1, below). The test sensors (with the lubricious coating) had a substantially increased sensitivity (m) but with no corresponding increase in constant noise (b), when compared to control sensors (no lubricious coating). Accordingly, it was shown that application of a lubricious coating over a polyurethane blend resistance domain of a glucose sensor can (in vitro) ...

example 3

[0443]Discontinuous Hydrophilic Overcoat on Resistance Domain Configured to Reduce Non-Constant Noise

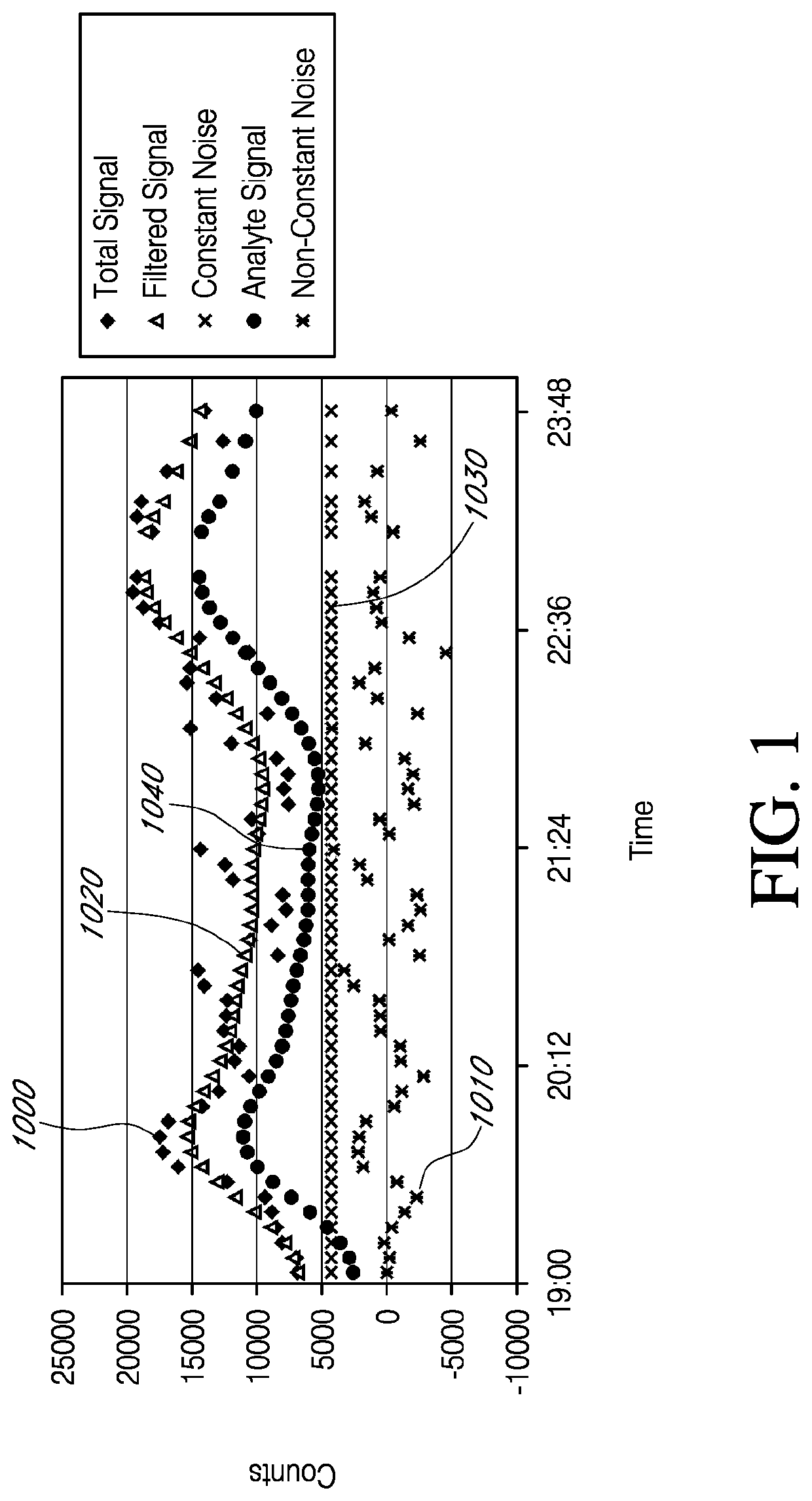

[0444]To determine if a hydrophilic overcoat on the resistance layer can increase the analyte signal component and / or reduce the non-constant noise component, test and control sensors were build and tested in volunteer human hosts, over a period of 3 days. Both the test and control sensors included an electrode layer, an enzyme layer and a polyurethane blend resistance domain. The polyurethane blend used to form the resistance domain included 8% hydrophile (i.e., PEO). After fabrication, the test sensors were sprayed (one time) in a solution of 5% ChronoThane® H (about 25% PEO; CardioTech International, Wilmington, Mass., USA) and cured. Test and control sensors were implanted bilaterally in the abdomens of the volunteer human hosts. FIG. 10 is a graph showing test results from one exemplary sensor. Components of the Total Signal 1000 were determined, as described in Example 1. The Y...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com